Under normal conditions, the radioactive element uranium is a metal having a large atomic (molecular) mass - 238.02891 g / mol. According to this indicator, he ranks second, because. only plutonium is heavier than it. Obtaining uranium is associated with the successive implementation of a number of technological operations:

- rock concentration, its crushing and precipitation of heavy fractions in water

- concentrate leaching or oxygen purge

- transfer of uranium to a solid state (oxide or tetrafluoride UF 4)

- obtaining uranyl nitrate UO 2 (NO 3) 2 by dissolving raw materials in nitric acid

- crystallization and calcination to obtain oxide UO 3

- reduction with hydrogen to obtain UO 2

- obtaining tetrafluoride UF 4 by adding gaseous hydrogen fluoride

- reduction of uranium metal with magnesium or calcium

uranium minerals

The most common U minerals are:

- Nasturan (uraninite) - the most famous oxide, which is called "heavy water"

- Carnotite

- Tuyamunit

- Thorbernite

- Samarskit

- brannerite

- Casolite

- slander

Uranium production

According to the Russian company Rosatom, one of the world leaders in the global uranium market, over 3,000 tons of uranium were mined on the planet in 2014. At the same time, according to representatives of the mining division of this state corporation, the volume of Russian reserves of this metal is 727.2 thousand tons (3rd place in the world), which guarantees an uninterrupted supply of the necessary raw materials for many decades.

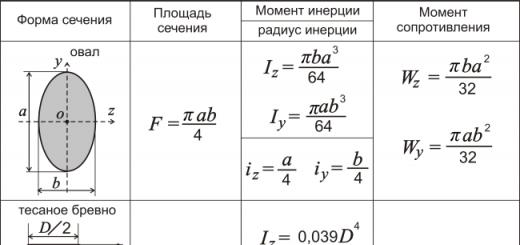

Main Chemical properties uranium are presented in the table:

The element U, like curium and plutonium, is an artificial element of the actinide family. Its chemical properties are in many ways similar to those of tungsten, molybdenum and chromium. Uranium is characterized by variable valency, as well as a tendency to form (UO 2) + 2 - uranyl, which is a complex ion.

Uranium enrichment methods

As you know, natural U contains 3 isotopes:

- 238U (99.2745%)

- 235U (0.72%)

- 234U (0.0055%)

Uranium enrichment is understood as an increase in the proportion of the 235U isotope in the metal, the only one that is capable of an independent nuclear chain reaction.

To understand how uranium is enriched, it is necessary to take into account the degree of its enrichment:

- content 0.72% - can be used in some power reactors

- 2-5% - used in most power reactors

- up to 20% (low enriched) - for experimental reactors

- more than 20% (highly enriched or weapons-grade) - nuclear reactors, weapons.

How is uranium enriched? There are many methods for enriching uranium, but the following are the most applicable:

- electromagnetic - acceleration elementary particles in a special accelerator and their twisting in a magnetic field

- aerodynamic - blowing gaseous uranium through special nozzles

- gas centrifugation - the uranium gas in the centrifuge moves and by inertia pushes heavy molecules to the walls of the centrifuge

- gas diffusion method of uranium enrichment - "sifting" of light isotopes of uranium through small pores of special membranes

The main scope of uranium is fuel for nuclear reactors, reactors nuclear power plants, nuclear power plants. In addition, the 235U isotope is used in nuclear weapons, while the unenriched metal with a high proportion of 238U makes it possible to obtain secondary nuclear fuel - plutonium.

Uranium, as a chemical element, was discovered in 1789, and its radioactive properties were revealed at the end of the 19th century. In the last century, uranium has only been used to make nuclear weapons. And nowadays it is widely used in many industries, for example, it is added in small quantities to glass for coloring. But to a greater extent it is used to create electrical energy.The scariest on the planet

Characteristics of uranium ores

Uranium ores are natural formations containing metal in significant concentrations. Often, other radioactive elements, such as polonium and radium, are found in the ore along with uranium.

- coarse-grained - in diameter over 25 mm;

- medium-grained - from 3 to 25 mm;

- fine-grained - from 0.1 to 3 mm;

- fine-grained - from 0.015 to 0.1 mm;

- dispersed - less than 0.015 mm.

The size of the grains determines how the enrichment will be carried out.

uranium ore classified according to the content of impurities;

- uranium-molybdenum;

- uranium-cobalt-nickel-bismuth;

- uranium-vanadium;

- monoore.

According to the chemical composition, ore is distinguished:

- silicate;

- carbonate;

- sulfide;

- iron oxide;

- caustobiol.

The chemical composition determines how the rock will be processed. For example:

- uranium is separated from carbonate ores by a soda solution;

- from silicate - acid;

- from iron oxide - by blast-furnace smelting.

Ore is classified by uranium content:

- very rich - contains over 1% of the metal;

- rich - from 1 to 0.5%;

- medium - from 0.5 to 0.25%;

- ordinary - from 0.25 to 0.1%;

- poor - less than 0.1%.

From the rock, which contains uranium in the range of 0.01 - 0.015%, the metal is extracted as a by-product.

Uranium deposits in Russia

- Zherlovoye - located in the Chita region, the reserves are estimated at 4137 thousand tons. In terms of metal content - molybdenum - 0.082% uranium and 0.227% molybdenum. Pure uranium is only 3485 tons;

- Argunskoye - located in the Chita region. Category C1 ore reserves are 13,025 thousand tons, of which 27,957 tons are uranium, and 7,990 thousand tons are category C2, of which 9,481 tons are pure uranium. This is the largest deposit. It provides 93% of the total Russian production volume;

- Istochnoye, Dybrynskoye, Kolichkanskoye, Koretkondinskoye are deposits located in the Republic of Buryatia. In this area, the explored reserves are about 17.7 thousand tons, and the predicted resources are 12.2 thousand tons;

- Khiagdinskoye is located in Buryatia. Uranium ore reserves - 11.3 thousand tons.

According to experts, the most promising deposits in Russia are currently at the development stage:

- Elkonskoye - located in Yakutia, according to forecasts, there are 346 thousand tons of ore;

- Malinovskoe - in Western Siberia;

- Vitim and Aldan - in Eastern Siberia;

- Far East - located on the coast of the Sea of \u200b\u200bOkhotsk;

- In Karelia near Onega and Ladoga lakes.

The total uranium reserves in Russia are estimated at 800 thousand tons.

How uranium ore is mined

Uranium deposits in Russia are developed in two ways:

- open;

- underground.

The extraction of uranium by the open method is carried out in the case when the layers of useful rock lie not deep underground.

For the extraction of ores, machinery is used:

- bulldozers - for opening the rock;

- bucket loaders;

- dump trucks for transportation.

An obligatory condition for open pit mining in Russia is its subsequent closure. It is carried out by covering layers, and reclamation is carried out on the restored surface.

The open method is safer and cheaper. It is believed that the level of radiation in such a development is much lower. But the quality of the ore is also low.

Higher grade ore is mined underground. It consists in the equipment of mines or adits. Today, technical capabilities do not limit production in depth, but exceeding two kilometers makes production unprofitable.

Higher grade ore is mined underground. It consists in the equipment of mines or adits. Today, technical capabilities do not limit production in depth, but exceeding two kilometers makes production unprofitable. The main problem of underground mining is radon emissions - radioactive gas. It can spread rapidly and create high concentrations in the mine atmosphere. One radon atom lives for 5 days. The main task in the design of the mine is to provide an effective ventilation system. So that gas atoms do not accumulate, but rise to the surface. Often ventilation systems and pipes are used not to supply oxygen to the mine, but to remove radon. Air is supplied artificially. The PIMCU mine in Russia consumes 1410 m 3 of air per minute. The ventilation units operate continuously, even when the mine is not in operation.

The underground leaching method is a modern progressive technology. Its use causes the least damage to the ecology of the region. The essence of the method is as follows:

- a well is being drilled;

- an alkaline composition is pumped into it;

- after interaction with uranium rock, the metal is leached;

- uranium-rich chemical composition pumped to the surface.

Despite the significant advantages, this method can only be used in sandstone and below the groundwater level.

The situation in the world

Today, uranium mining is carried out only in 28 countries of the world. At the same time, 90% of the deposits are located in 10 countries that are leaders in terms of production volumes.

First place Australia

Main characteristics:

- proven reserves - 661,000 tons (31.18% of global reserves);

- deposits - 19 large. The most famous:

- Olympic Dam - 3,000 tons per year are mined;

- Beaverley - one thousand tons per year;

- Honemun - 900 tons.

- production cost - $40 per kilogram;

- major mining companies:

- Paladin Energy;

- Rio Tinto;

- BHP Billiton.

Second place in terms of production in Kazakhstan

Basic data:

- proven reserves - 629,000 tons (11.81% of global reserves);

- deposits - 16 large. The most famous:

- Korsan;

- Irkol;

- Budenovskoye;

- Western Mynkuduk;

- Southern Inkai;

- production cost - $40 per kg;

- production volume - 22574 tons per year;

- the mining company is Kazatomprom (producing 15.77% of the global volume).

Third place for Russia

Indicators:

Fourth place - Canada

Indicators:

- proven reserves – 468,000 tons (8.80% of global reserves);

- deposits - 18 large. The most famous:

- MacArthur River;

- Waterbury;

- production cost - $34 per kilogram;

- production volume - 9332 tons per year;

- mining company - Cameco (produces 9144 tons of uranium per year).

Fifth place - Niger

- proven reserves - 421,000 tons (7.9% of global reserves);

- Place of Birth:

- Imuraren;

- Arlit;

- Madauela;

- Azelite;

- production cost - $35 per kilogram;

- production volume - 4528 tons per year.

The second five countries in terms of uranium reserves are as follows:

- South Africa - 297,000 tons;

- Brazil - 276,000 tons;

- Namibia - 261,000 tons;

- USA - 207,000 tons;

- China - 166,000 tons.

According to experts, by 2025 the number of nuclear power plants. This growth will provoke greater demand for uranium - an increase of 44% (80-100 thousand tons). Therefore, there is a worldwide trend towards the use of secondary sources of uranium:

- gold;

- phosphates;

- copper;

- lignite-bearing rocks.

Video: How uranium is mined

A feature of the development of uranium deposits is the possibility of using for them both conventional mining methods of extraction (open pit and underground), and methods of underground (borehole, block) and heap leaching. Prevalence in the world various ways uranium mining: underground 37%, open pit 24%, associated mining 18%, downhole in-situ leaching 12%, undetermined 7%.

In the mining and production of uranium, various precautions are taken to protect the health of personnel:

- - Dust levels are carefully controlled to minimize the ingestion of γ- or α-emitting substances. Dust is the main source of radioactive exposure. It typically contributes 4 mSv/yr to the annual dose received by personnel.

- - The external radioactive exposure of personnel in mines, factories and waste disposal sites is limited. In practice, the level of external exposure from ore and waste is usually so low that it has little effect on increasing the allowable annual dose.

- - Natural ventilation of open deposits reduces the level of exposure from radon and its daughter isotopes. The level of exposure from radon does not exceed 1% of the level allowed for continuous exposure of personnel. Underground mines are equipped with ventilation systems to achieve the same level. In Australian and Canadian underground mines, the average exposure dose is ~3 mSv/year.

- - There are strict hygienic standards for the work of personnel with uranium oxide concentrate, because it is chemically toxic, like lead oxide. In practice, precautions are taken to protect the respiratory system from the ingress of toxins, similar to those used when working in lead smelters.

Let us dwell on the main methods of extracting uranium raw materials in more detail.

Mine method of uranium mining- one of the main ways of uranium production. The organization of work is similar to the methods of mining other metals, but there are differences. Uranium ores occur most often in the form of narrow layers, which leads to the formation of a mine in the form of branched drifts. Since the development of uranium ore is carried out on the same horizon with the formation of drifts and treatment blocks located near the main haulage, the formation of dust is largely localized. The absence of air circulation from one block to another does not cause their mutual pollution, and the formation of dust in uranium mines is not great.

During the operation of underground uranium mines, the mine waters are constantly pumped out and sent to the hydrometallurgical plant in a closed technological water circulation system. Powerful ventilation does not allow the concentration of radon in the air. If ventilation is turned off after the end of the work shift, then the atmospheric concentrations of radon and its daughter products increase sharply, and therefore, before the start of the next shift, these concentrations must be reduced to the maximum allowable

The main danger to uranium miners comes from inhaling air containing radon released from the ore. IN uranium ores, except for uranium, contains all other members of the radioactive series, in which it is the parent nuclide. The following elements of this family pose the greatest danger to the health of miners: 222 Rn, 21t *Pb, 211 Bi and 21 "Po. The content of radon in the atmosphere of the mine is determined by the rate of emanation, the rate of ventilation and the half-life of radon. The immediate progeny of radon decay have a short half-life and quickly accumulate in the atmosphere, even if radon enters the mine without progeny.

Due to the fact that the relative hazard of radon daughter products is greater than the hazard of radon itself, control over radioactive contamination air in uranium mines can be carried out by the products of its decay. As an acceptable working level of the content of the daughter products of radon decay in the mine atmosphere, the value of "latent energy", equal to 1.3 * 105 MeV / l of air, is proposed.

Open pits (some of them up to 500 m deep) are a popular way to mine uranium. It is believed that the radiation hazard of such quarries for miners is much less than underground mines. However, for environment open pit mining of uranium can pose a serious danger due to dust entrainment. Landscape changes, vegetation disturbance, adverse impacts on local fauna are inevitable consequences open development. It is a difficult task to backfill the quarry with waste rock and recultivate after the completion of mining operations.

There are rules and laws that define measures to protect the environment, stipulate requirements such as preliminary

environmental impact assessments; gradual implementation of a restoration program, including restoration of landscapes and forest areas, planting of endogenous flora, restoration of endogenous wildlife; as well as checking the compliance of the state of the environment with existing regulations.

Rice. 4. Extraction of uranium by underground leaching.

Mining by dissolution

(in situ leaching) involves introducing an alkaline or acidic liquid (such as sulfuric acid) through wells into a uranium ore deposit and pumping it back out. This method does not require removal of the ore from the mining site, but can only be used where the uranium deposits are located in an aquifer in permeable rock and not too deep (-200 m).

The advantages of this technology are the reduced risk of accidents and exposure for personnel, low cost, and not much space required for waste storage. The main disadvantages are the risk of diversion of leaching fluids from the uranium deposit and subsequent contamination of groundwater, and the impossibility of restoring natural conditions in the leaching zone after the completion of operations. The resulting contaminated mixture is either transferred to reservoirs or sent to deep liquidation wells.

Leaching - extraction of one or more components from ores, concentrates, production waste aqueous solution containing an alkali, acid or other reagent, as well as using certain types of bacteria; special case extraction from the solid phase. Usually leaching is accompanied chemical reaction, as a result of which the extracted component passes from a form that is insoluble in water to a soluble one.

Underground leaching - leaching at the place of occurrence of uranium ores. It involves injecting sulfuric acid into the ore mass and eliminates the problem of tailings storage, but under adverse conditions can cause groundwater pollution.

Leaching is based on the ability of the extracted substance to dissolve better than the rest. Solvents - a solution of ammonia, acids, alkalis, metal chlorides or chlorine, sulfates, etc. Leaching may be accompanied by the oxidation of the extracted material in order to convert sparingly soluble compounds into easily soluble ones (oxidative leaching). As an oxidizing agent, gases (air, oxygen), liquid and solid are used. inorganic substances(HN0 3 , Mn0 2 , KMn0 4 and others), bacteria (bacterial leaching).

Borehole underground leaching is used in the development of reservoir deposits. The conditions for its applicability are the high permeability and water content of the ore-bearing medium. When using this method, the field is divided into polygons, drilled successively by systems of injection and extraction wells, and there are two or three or more extraction wells for one injection well. The leaching time of uranium from rocks at each test site is 1^-3 years. Depending on the composition of the working solutions used, an acid uranium leaching scheme (solutions of sulfuric acid) and a carbonate scheme (solutions of sodium and ammonium carbonates-bicarbonates) are distinguished.

In-situ leaching consists in supplying a leaching solution underground directly into the ore body or into a layer of specially prepared ore and pumping the solution that has seeped through the ore layer to the surface. There are two main options for underground leaching - downhole (shaftless) and mine (block). In underground mines, old or specially created mines, prepared underground chambers with collapsed ore are used, and adits or drifts are used to collect the production solution.

Underground leaching, usually used at an ore body depth of no more than 100 m, makes it possible to involve low-grade uranium ores in the mining industry, drastically reduce the volume of capital investments and the construction time of enterprises, increase labor productivity by several times, and significantly reduce harmful effect on nature (not to disturb the landscape, to drastically reduce the amount of solid waste and harmful substances carried to the surface of the earth, and it is relatively easy to restore waste areas).

Underground borehole leaching is a method of developing ore deposits without raising the ore to the surface by selectively transferring natural uranium ions into a productive solution directly in the subsoil. This method is carried out by drilling wells through uranium ore bodies, supplying a solution to uranium ore bodies, lifting uranium-containing solutions to the surface and extracting uranium from them in sorption ion-exchange units, adding acid to mother liquors and pumping them back into the bowels. During borehole leaching, there is no change in the geological state of the subsoil, since the mining mass is not excavated.

In the process of borehole leaching, less than 5% of radioactivity passes into a mobile state in the subsoil and is brought to the surface, compared with 100% with traditional methods of uranium mining. There is no need to build tailings for storing waste with a high level of radiation. The natural hydrogeochemical environment in uranium deposits is usually capable of self-healing from technogenic impact. Due to the gradual restoration of natural redox conditions, a slow but irreversible process of reclamation of groundwater in ore-bearing aquifers occurs. There are methods of significant intensification of this process, accelerating reclamation tenfold.

Nevertheless, the borehole leaching method is quite dangerous from an environmental point of view. Leaching uranium-containing solution can flow out of the ore body of the zone through fractures in the rock or ruptures in waterproofing layers and then spread through the aquifer. This can lead to groundwater contamination at long distances from the mine. In addition to uranium, leaching solutions also dissolve other minerals, as a result of which not only uranium becomes mobile, but also elements: radium, arsenic, vanadium, molybdenum, cadmium, nickel, lead, etc., and they are concentrated a thousand times. Minerals precipitate out of solution during the in-situ leaching process, forming calcite, gypsum and other minerals. The resulting precipitation can reduce or even completely block the flow of solution through uranium-bearing areas, leading to unpredictable results or premature closure of the mine.

Borehole leaching produces large quantities Wastewater and solutions to be disposed of in an environmentally sound manner. These include wash water and liquid waste from the uranium enrichment plant. These fluids are mixed and re-injected into the same groundwater used in uranium mining, or injected into a deep aquifer far away from other groundwater users. These liquid wastes contain high concentrations of radionuclides and heavy metals, and the area of their distribution needs to be restored after the closure of the mine.

Heap leaching is the process of obtaining useful components by dissolving prepared (crushed poor ores or tailings of a processing plant) and placed in a special pile of mineral raw materials, followed by their separation (precipitation) from circulating solutions.

Heap leaching is used to process ores containing readily soluble useful components; such ores must be relatively porous and inexpensive. Occasionally, heap leaching is used to treat tailings resulting from prior mining processes. To load the ore, a slightly inclined surface is prepared, impervious to leaching solutions. Drainage basins are created along and across this surface for drainage. After loading, the ore is poured with an amount of leaching solution sufficient to saturate its entire thickness. The solution penetrates between the ore particles and produces the dissolution of useful components. After a certain period of time, the material is dried and the crust formed by the dissolved valuable components is removed, and the treated loose rock is washed into the drainage system.

Percolation leaching is used in the processing of ores that do not grind well when crushed and do not contain natural sludge or clay. This is a rather slow process. Seepage leaching is carried out in tanks that are well suited for loading and unloading. The bottom of the tank should be an effective filter, allowing the pumping and pumping of the solution through it. The tanks are loaded with crushed ore of a certain size fraction. Then the leaching solution is pumped into the tank and absorbed into the ore After the required holding time has elapsed, the solution with the leached components is pumped out, and the ore is washed to remove the remaining leaching solution.

During the leaching process, emissions of dust, radon and leaching liquid are possible. After the completion of the leaching process, especially if the ore contains iron sulfide, then after its access to water and air, continuous bacterial production of acid in the dumps can begin, which leads to spontaneous leaching of uranium for many centuries with contamination of groundwater.

In the last few years, the topic of nuclear energy has become increasingly relevant. For the production of atomic energy, it is customary to use a material such as uranium. It is a chemical element belonging to the actinide family.

The chemical activity of this element determines the fact that it is not contained in a free form. For its production, mineral formations called uranium ores are used. They concentrate such an amount of fuel that allows you to calculate the production of this chemical element economically rational and profitable. On the this moment in the bowels of our planet, the content of this metal exceeds the reserves of gold in 1000 times(cm. ). In general, the deposits of this chemical element in the soil, aquatic environment and rock are valued at more than 5 million tons.

In the free state, uranium is a gray-white metal, which is characterized by 3 allotropic modifications: rhombic crystal, tetragonal and body-centered cubic lattices. The boiling point of this chemical element is 4200°C.

Uranium is a chemically active material. In air, this element slowly oxidizes, easily dissolves in acids, reacts with water, but does not interact with alkalis.

Uranium ores in Russia are usually classified according to various criteria. Most often they differ in terms of education. Yes, there are endogenous, exogenous and metamorphogenic ores. In the first case, they are mineral formations formed under the influence of high temperatures, humidity and pegmatite melts. Exogenous uranium mineral formations occur in surface conditions. They can form directly on the surface of the earth. This is due to the circulation of groundwater and the accumulation of precipitation. Metamorphogenic mineral formations appear as a result of the redistribution of initially spaced uranium.

According to the level of uranium content, these natural formations can be:

- super-rich (over 0.3%);

- rich (from 0.1 to 0.3%);

- ordinary (from 0.05 to 0.1%);

- poor (from 0.03 to 0.05%);

- off-balance sheet (from 0.01 to 0.03%).

Modern applications of uranium

Today, uranium is most commonly used as a fuel for rocket engines and nuclear reactors. Given the properties of this material, it is also intended to increase the power of a nuclear weapon. This chemical element has also found its application in painting. It is actively used as yellow, green, brown and black pigments. Uranium is also used to make cores for armor-piercing projectiles.

Uranium ore mining in Russia: what is needed for this?

The extraction of radioactive ores is carried out by three main technologies. If ore deposits are concentrated as close as possible to the surface of the earth, then it is customary to use open technology for their extraction. It involves the use of bulldozers and excavators that dig large holes and load the resulting minerals into dump trucks. Then it goes to the processing complex.

With a deep occurrence of this mineral formation, it is customary to use underground mining technology, which provides for the creation of a mine up to 2 kilometers deep. The third technology differs significantly from the previous ones. In-situ leaching for the development of uranium deposits involves drilling wells through which sulphuric acid. Next, another well is drilled, which is necessary for pumping the resulting solution to the surface of the earth. Then it goes through a sorption process, which allows collecting salts of this metal on a special resin. The last stage of the SPV technology is the cyclic treatment of the resin with sulfuric acid. Thanks to this technology, the concentration of this metal becomes maximum.

Deposits of uranium ores in Russia

Russia is considered one of the world leaders in the extraction of uranium ores. Over the past few decades, Russia has consistently been in the top 7 leading countries in this indicator.

The largest deposits of these natural mineral formations are:

The largest uranium mining deposits in the world - leading countries

Australia is considered the world leader in uranium mining. More than 30% of all world reserves are concentrated in this state. The largest Australian deposits are Olympic Dam, Beaverley, Ranger and Honeymoon.

Australia's main competitor is Kazakhstan, which contains almost 12% of the world's fuel reserves. Canada and South Africa each contain 11% of the world's uranium reserves, Namibia - 8%, Brazil - 7%. Russia closes the top seven with 5%. The leaderboard also includes countries such as Namibia, Ukraine and China.

The world's largest uranium deposits are:

| Field | The country | Start processing |

| Olympic Dam | Australia | 1988 |

| Rossing | Namibia | 1976 |

| MacArthur River | Canada | 1999 |

| Inkai | Kazakhstan | 2007 |

| Dominion | South Africa | 2007 |

| Ranger | Australia | 1980 |

| Kharasan | Kazakhstan | 2008 |

Reserves and production volumes of uranium ore in Russia

Explored reserves of uranium in our country are estimated at more than 400,000 tons. At the same time, the indicator of predicted resources is more than 830 thousand tons. As of 2017, there are 16 uranium deposits operating in Russia. Moreover, 15 of them are concentrated in Transbaikalia. The Streltsovskoye ore field is considered the main deposit of uranium ore. In most domestic deposits, mining is carried out by the mine method.

- Uranus was discovered in the 18th century. In 1789, the German scientist Martin Klaproth managed to produce metal-like uranium from ore. Interestingly, this scientist is also the discoverer of titanium and zirconium.

- Uranium compounds are actively used in the field of photography. This element is used to color positives and enhance negatives.

- The main difference between uranium and other chemical elements is natural radioactivity. Uranium atoms tend to change independently over time. At the same time, they emit rays invisible to the human eye. These rays are divided into 3 types - gamma, beta alpha radiation(cm. ).

In a message from the Ambassador of Iraq to the UN Mohammed Ali al-Hakim dated July 9, it says that at the disposal of extremists ISIS (Islamic State of Iraq and the Levant). The IAEA (International Atomic Energy Agency) hastened to declare that the nuclear substances used by Iraq earlier have low toxic properties, and therefore materials captured by the Islamists.

A U.S. government source familiar with the situation told Reuters that the uranium stolen by the militants is likely not enriched and therefore unlikely to be used to make nuclear weapons. The Iraqi authorities officially notified the United Nations about this incident and called for "preventing the threat of its use," RIA Novosti reports.

Uranium compounds are extremely dangerous. About what exactly, as well as about who and how can produce nuclear fuel, says AiF.ru.

What is uranium?

Uranium is a chemical element with atomic number 92, a silvery-white shiny metal, periodic system Mendeleev is designated by the symbol U. In its pure form, it is slightly softer than steel, malleable, flexible, contained in earth's crust(lithosphere) and in sea water and rarely found in its pure form. Nuclear fuel is made from uranium isotopes.

Uranium is a heavy, silvery-white, shiny metal. Photo: Commons.wikimedia.org / Original uploader was Zxctypo at en.wikipedia.

Radioactivity of uranium

In 1938 the German physicists Otto Hahn and Fritz Strassmann irradiated the nucleus of uranium with neutrons and made a discovery: capturing a free neutron, the nucleus of the uranium isotope is divided and releases enormous energy due to the kinetic energy of the fragments and radiation. In 1939-1940 Julius Khariton And Yakov Zel'dovich for the first time theoretically explained that with a slight enrichment of natural uranium with uranium-235, it is possible to create conditions for continuous fission atomic nuclei, that is, to give the process a chain character.

What is enriched uranium?

Enriched uranium is uranium produced by technological process of increasing the proportion of the 235U isotope in uranium. As a result, natural uranium is divided into enriched uranium and depleted uranium. After the extraction of 235U and 234U from natural uranium, the remaining material (uranium-238) is called "depleted uranium", since it is depleted in the 235th isotope. According to some reports, about 560,000 tons of depleted uranium hexafluoride (UF6) are stored in the United States. Depleted uranium is half as radioactive as natural uranium, mainly due to the removal of 234U from it. Due to the fact that the main use of uranium is energy production, depleted uranium is a low-use product with low economic value.

Nuclear power uses only enriched uranium. The uranium isotope 235U has the greatest application, in which a self-sustaining nuclear chain reaction is possible. Therefore, this isotope is used as fuel in nuclear reactors and in nuclear weapons. Separation of the isotope U235 from natural uranium is a complex technology that few countries can implement. Uranium enrichment allows the production of atomic nuclear weapons - single-phase or single-stage explosive devices in which the main energy output comes from nuclear reaction fission of heavy nuclei to form lighter elements.

Uranium-233, artificially produced in reactors from thorium (thorium-232 captures a neutron and turns into thorium-233, which decays into protactinium-233 and then into uranium-233), may in the future become a common nuclear fuel for nuclear power plants (already now there are reactors using this nuclide as fuel, for example KAMINI in India) and production atomic bombs(critical mass about 16 kg).

The core of a 30 mm caliber projectile (GAU-8 guns of the A-10 aircraft) with a diameter of about 20 mm from depleted uranium. Photo: Commons.wikimedia.org / Original uploader was Nrcprm2026 at en.wikipedia

Which countries produce enriched uranium?

- France

- Germany

- Holland

- England

- Japan

- Russia

- China

- Pakistan

- Brazil

10 countries providing 94% of the world's uranium production. Photo: Commons.wikimedia.org / KarteUrangewinnung

Why are uranium compounds dangerous?

Uranium and its compounds are toxic. Aerosols of uranium and its compounds are especially dangerous. For aerosols of water-soluble uranium compounds, the maximum allowable concentration (MPC) in the air is 0.015 mg / m³, for insoluble forms of uranium, the MAC is 0.075 mg / m³. When it enters the body, uranium acts on all organs, being a general cellular poison. Uranus is practically irreversible, like many others heavy metals, binds to proteins, primarily to the sulfide groups of amino acids, disrupting their function. The molecular mechanism of action of uranium is associated with its ability to inhibit the activity of enzymes. First of all, the kidneys are affected (protein and sugar appear in the urine, oliguria). With chronic intoxication, hematopoietic and nervous system disorders are possible.

The use of uranium for peaceful purposes

- A small addition of uranium gives a beautiful yellow-green color to the glass.

- Sodium uranium is used as a yellow pigment in painting.

- Uranium compounds were used as paints for painting on porcelain and for ceramic glazes and enamels (colored in colors: yellow, brown, green and black, depending on the degree of oxidation).

- At the beginning of the 20th century, uranyl nitrate was widely used to enhance negatives and stain (tint) positives (photographic prints) brown.

- Alloys of iron and depleted uranium (uranium-238) are used as powerful magnetostrictive materials.

Isotope - varieties of atoms of a chemical element that have the same atomic (ordinal) number, but different mass numbers.

Group III element of the periodic table, belonging to the actinides; heavy weakly radioactive metal. Thorium has a number of applications in which it sometimes plays an indispensable role. The position of this metal in the periodic system of elements and the structure of the nucleus predetermined its use in the field of peaceful use of atomic energy.

*** Oliguria (from the Greek oligos - small and ouron - urine) - a decrease in the amount of urine separated by the kidneys.