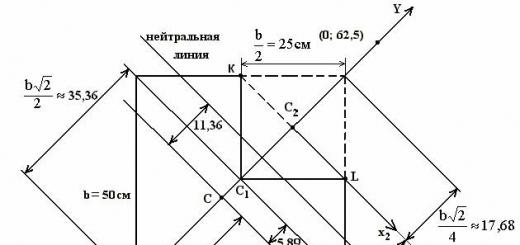

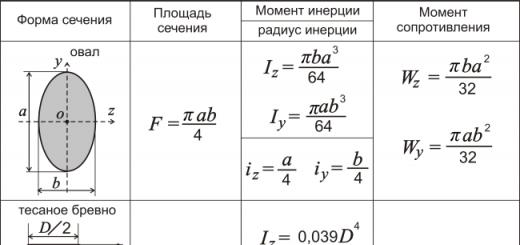

Figure 1: Surfactants: scheme of action

Sodium and potassium salts of higher fatty acids (soaps) are surfactants capable of forming persistent soap films. Surfactants (surfactants) can be located in a certain way at the interface between two phases, for example, such as water - air or water - oil. This behavior of surfactants is explained by the peculiarity of their structure: a surfactant molecule, such as soap, includes both a polar, hydrophilic group capable of ionization, and a non-polar hydrophobic part - hydrocarbon. At the phase boundary, the hydrophilic group is oriented towards water, and the hydrocarbon radical is oriented towards the oil phase or air.

Figure 2: Soap micelles

AT aquatic environment at certain concentration Surfactant molecules no longer exist as isolated particles, but as large aggregates—micelles, in which all hydrocarbon groups are in the center of the micelle, and hydrophilic groups are outside (Fig. 2a). A micelle is capable of “capturing” particles of water-insoluble substances and creating persistent ones, since the micelles are prevented from sticking together by the same charge of their surfaces (Fig. 2b). The washing effect of soaps is based on this principle. Pollution is a fatty film with dust particles. Soaps emulsify dirt, after which the emulsion is easily washed off with water.

Synthetic surfactants and detergents

For the production of soap a large number of Fats are a valuable food and technical product. Meanwhile, other surfaces also have surface activity. organic compounds having a similar structure to soaps.

These include:

- anionic surfactants(For example, sodium salts of alkyl sulfates, alkylsulfonates);

- cationic surfactants(e.g. quaternary alkylammonium salts)

Figure 3: Synthetic surfactant formulas

Anionic and cationic surfactants necessarily contain a long alkyl radical in the molecule (From 12 - From 14)

Synthetic surfactants are obtained in industry from available hydrocarbon raw materials, mainly oil, so they are inexpensive. Another advantage of detergents based on synthetic surfactants is that they can be used in hard water, in which ordinary soaps produce insoluble calcium and magnesium salts, which reduces the effectiveness of the washing action and increases soap consumption.

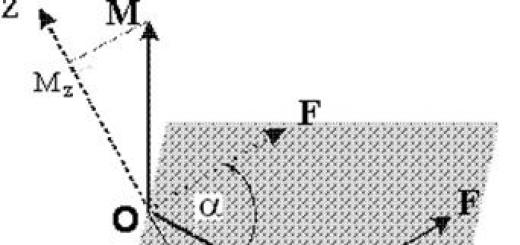

Twins

Figure 4: General formula twins

AT recent times wide application in industry (for example, in textiles) find surfactants twins. In pharmacy, they serve as a synthetic emulsifying base in the manufacture of ointments.

Twins are built according to general principle, like other surfactants, that is, their molecules contain non-polar and polar parts. The basis of the molecule is a cyclic tetrahydric alcohol sorbitan, in which one to three hydroxyl groups are esterified with higher fatty acids. The radicals of these acids make up the non-polar part of the molecule.

The remaining hydroxyl groups form an ether bond with polyethylene glycol residues - (CH 2 CH 2 O) n CH 2 CH 2 OH, where n=40-80. Fragments of polyethylene glycol represent the polar part of the twins.

Bibliography: Organic chemistry, A.P. Luzin, S.E. Zurabyan, N.A. Tyukavkina, 1998

Or CMC), with the achievement of which, when a surfactant is added to a solution, the concentration at the phase boundary remains constant, but at the same time, self-organization of surfactant molecules in a bulk solution (micelle formation or aggregation) occurs. As a result of this aggregation, so-called micelles are formed. A distinctive feature of micelle formation is the turbidity of the surfactant solution. Aqueous solutions of surfactants, during micelle formation, also acquire a bluish tint (gelatinous tint) due to the refraction of light by micelles.

Methods for determining CMC:

- Surface tension method

- Method for measuring the contact angle (wetting angle) with TV. or liquid surface (Contact angle)

- Spindrop/Spinning drop method

Encyclopedic YouTube

-

1 / 5

As a rule, surfactants are organic compounds that have amphiphilic structure, that is, their molecules contain a polar part, a hydrophilic component (functional groups -OH, -COOH, -SOOOH, -O-, etc., or, more often, their salts -ONa, -COONa, -SOOONa and etc.) and a non-polar (hydrocarbon) part, a hydrophobic component. An example of a surfactant is ordinary soap (a mixture of sodium salts of fatty carboxylic acids - oleate, sodium stearate, etc.) and SMS (synthetic detergents), as well as alcohols, carboxylic acids, amines, etc.

Surfactant classification

The use of higher fatty alcohols for the production of surfactants

Surfactant class Type of surfactant Chemical formula Reagent for synthesis Synthesis scheme Sources Nonionic surfactants alkoxylates ethoxylates R−O−(CH 2 CH 2 O) n H ethylene oxide ROH + n(CH 2 CH 2)O → RO−(CH 2 CH 2 O) n H The reaction proceeds in the presence of alkali at temperatures up to 160°C and pressures up to 0.55 MPa. Usually use C 9 -C 15 alcohols in combination with 6-7 moles of ethylene oxide.

:[p. 31, 35] :[p. 137-139] propoxylates R−O−(CH 2 CH(CH 3)O) n H propylene oxide butoxylates R−O−(CH 2 CH(C 2 H 5)O) n H butylene oxide Alkyl glycosides R−(O−C 6 H 10 O 5) n H glucose ROH + nC 6 C 12 O 6 → R−(O−C 6 H 10 O 5) n H+nH 2 O

The reaction proceeds in the presence of sulfonic acids at temperatures up to 140°C. Another option is the preliminary preparation of butyl ethers followed by transesterification. The number of glycosidic groups ranges from 1 to 3.:[p. 38]

:[p. 149]Anionic surfactants Carboxyethoxylates R−O−(CH 2 CH 2 O) n CH 2 COOH chloroacetic acid RO(CH 2 CH 2 O) n H + ClCH 2 COOH → RO(CH 2 CH 2 O) n CH 2 COOH + HCl The reaction proceeds in the presence of alkali, the acid is isolated by acidification of the aqueous solution and separation of the aqueous-salt phase.

:[p. 40]

:[p. 126-127]Phosphates and polyphosphates ROP(OH) 2 O; (RO) 2 P(OH)O phosphorus(V) oxide 3ROH + P 2 O 5 → ROP(OH) 2 O + (RO) 2 P(OH)O Addition of powdered phosphorus oxide to anhydrous alcohols in an anhydrous medium at 50-70°C with vigorous stirring.

:[p. 54]

:[p. 122-123]Sulfosuccinates ROC(O)CH 2 CH(SO 3 Na)COOH; ROC(O)CH 2 CH(SO 3 Na)COOR maleic anhydride, sodium sulfite ROH + (COCH=CHCO)O → ROC(O)CH=CHCOOH

ROC(O)CH=CHCOOH + Na 2 SO 3 → ROC(O)CH 2 CH(SO 3 Na)COONa

Etherification of alcohols with raspberry anhydride (T up to 100 ° C) and further addition to sodium sulfite ether by heating.:[p. 52-53] Alkyl sulfates R-O-SO 3 H sulfuric acid, sulfur(VI) oxide, chlorosulfonic acid ROH + SO 3 → ROSO 3 H

Direct sulfonation of alcohols with subsequent neutralization of the solution with alkali.:[p. 55-56] Alkyl ether sulfates R−(CH 2 CH 2 O) n OSO 3 H Some other alcohols are also used in the production of surfactants: glycerin (esters with fatty acids - emulsifiers), sorbitol (sorbitans), monoethanolamine and diethanolamine (alkanolamides).

Effect of surfactants on environmental components

Surfactants are divided into those that are rapidly destroyed in environment and those that are not destroyed and can accumulate in organisms in unacceptable concentrations. One of the main negative effects of surfactants in the environment is a decrease in surface tension. For example, in the ocean, a change in surface tension leads to a decrease in the retention of CO 2 and oxygen in the body of water. Only a few surfactants are considered safe (alkylpolyglucosides), since their degradation products are carbohydrates. However, when surfactants are adsorbed on the surface of earth/sand particles, the degree/rate of their degradation decreases many times over. Since almost all surfactants used in industry and households have a positive adsorption on particles of earth, sand, clay, under normal conditions they can release (desorb) heavy metal ions held by these particles, and thereby increase the risk of these substances entering the human organism.

Surfactants (surfactants) are chemical substances, which are able to concentrate at the phase boundaries and reduce the surface (interfacial) tension. Surfactants are used in pharmaceutical and cosmetic products, in the production of shampoos and foaming agents.

Chemical structure of surfactants

A surfactant molecule consists of a hydrophobic hydrocarbon radical and a hydrophilic polar (functional) group, i.e. the molecule is amphiphilic, as a result of which it has a high adsorption capacity. For example, in a water/oil emulsion, at the phase boundary, the hydrophilic group of the surfactant molecule is oriented towards water, and the hydrocarbon part is towards oil. At the same time, the interfacial tension decreases, which ensures the stabilization of oil droplets in water.

The detergent action of surfactants is based on the fact that the surface-active ingredients of lotions, shampoos, soaps are adsorbed on the surface of such contaminants as fat and solid particles, envelop and facilitate their transfer into the washing solution. Surfactants facilitate the spreading of water or products based on them over the skin surface by reducing interfacial tension.

Types of Surfactants

The classification of surfactants is based on the division, depending on the nature of the polar group: non-ionic, which do not dissociate into ions in water, and ionic, which, depending on the charge formed during dissociation in water, are divided into: anionic, cationic, amphoteric.

Anionic surfactants, when dissolved in water, form negatively charged ions with a long hydrocarbon chain (organic anions) and an ordinary cation. Anionic surfactant emulsifiers are very effective:

- when creating oil/water emulsions;

- when dispersing a number of powdered materials;

- when used in foam detergents for high foaming in hard water.

An example of an anionic surfactant that is often used in cosmetic formulations such as detergents is sodium lauryl ethoxysulfate (INCI nomenclature "Sodium Laureth Sulfate"). It is obtained by sulfation of saturated or unsaturated primary higher alcohols, followed by neutralization with sodium hydroxide, ammonia or triethanolamine. It is often produced in the form of a pasty mass containing up to 70% of the main substance.

Cationic surfactants, when dissolved in water, form positively charged ions (organic cations) and a low molecular weight anion. Cationic surfactants include salts of fatty amines and quaternary ammonium bases. Cationic emulsifiers are less effective than anionic emulsifiers, since they reduce surface tension to a lesser extent. But they exhibit bactericidal activity by interacting with cellular proteins of bacteria. Cationic surfactants are actively used in hair care products (shampoos, conditioners, hair conditioners). Aliphatic cationic surfactants with one and two hydrocarbon tails are good antistatic agents and are used in hair cosmetics.

Amphoteric surfactants, depending on the pH of the medium, behave in an alkaline environment as anionic or in an acidic environment as cationic. Their molecules contain functional groups that can have both negative and positive charges. Such surfactants are well compatible with cationic and anionic ones. Amphoteric surfactants are dermatologically gentle on the skin, which is why they are often used in “no tears” baby shampoos and products for sensitive skin. So, for example, in combination with an anionic surfactant sodium lauryl sulfate, almost completely soften its dermatological rigidity. Amphoteric surfactants have good foaming properties.

Betaines are one of the varieties of amphoteric surfactants. They belong to soft and high-foam surfactants. The amphoteric surfactant cocamidopropyl betaine (Dehiton / Betadet) is included in the composition of cosmetics in the production of shampoos, gels and cream-gels, liquid soaps, cleansing bath foams. This surfactant contributes to the compatibility of the cosmetic product with the skin, while improving the viscosity and foaming of this product. Thus, Dechiton, especially in children's foaming products, is an emollient component and contributes to the safety of using a detergent.

Non-ionic (non-ionic) surfactants are surfactants that do not form ions when dissolved in water. They, in comparison with anionic ones, having a weaker foaming ability, have a milder effect on the skin. Such surfactants are often used as emulsifiers, dispersants, solubilizers, as well as co-surfactants, foam stabilizers, wetting agents, etc. Fatty acid diethanolamides can be cited as an example of a nonionic surfactant. They are used in the production of shampoos and foaming detergents in an amount of up to 3% as a refatting agent, foam stabilizer and thickener.

In Russian-made shampoos, to achieve the necessary consumer properties and improve quality, they use various combinations Surfactants depending on the purpose of the cosmetic product.

Surfactants used in the cosmetic industry must comply with the Uniform Sanitary and Epidemiological and Hygienic Requirements for Products Subject to Sanitary and Epidemiological Surveillance (Control).

Benefits of using surfactants:

- lead to the stabilization of the dispersed system, make it impossible for the particles of the dispersed phase to stick together and coagulate;

- facilitate the process of dispersion and obtaining cosmetic compositions;

- improve the wettability and spreadability of cosmetic substances on the skin;

- provide stability of reverse emulsions;

- as part of foaming detergents, they improve their foaming and increase the stability of the foam during use.

Literature

Surfactants and compositions. Directory. Edited by M.Yu. Pletnev 2002. - p.40-44.

Fundamentals of cosmetic chemistry. Basic provisions and modern ingredients. Ed. Puchkova T.V. 2011, pp.122-133.

on several orders higher than in the liquid volume, therefore, even with a negligible content in water (0.01-0.1% by weight), surfactants can reduce surface tension water at the border with air from 72.8 10 -3 to 25·10 -3 J/m 2 , i.e. almost tosurface tension hydrocarbon liquids. A similar phenomenon takes place at the border water solution Surfactant is a hydrocarbon liquid, which creates prerequisites for the formation of emulsions.

Basic quantitative characteristic Surfactant is - the ability of a substance to reduce surface tension at the interface is the derivative of surface tension with respect to surfactant concentration as C tends to zero.

In the volume of the liquid phase, surfactants can contain

- or in the form of individual molecules (truly soluble surfactants),

-or combine into groups of several tens of molecules - The limiting concentration of surfactants in a solution, at which the formation of micelles begins, is called).Surfactant structure

As a rule, surfactants are organic compounds that have amphiphilic structure, that is, their molecules contain a polar part, a hydrophilic component (functional groups -OH, -COOH, -SOOOH, -O-, etc., or, more often, their salts -ONa, -COONa, -SOOONa and etc.) and a non-polar (hydrocarbon) part, a hydrophobic component. An example of a surfactant is ordinary soap (a mixture of sodium salts of fatty carboxylic acids - oleate, sodium stearate, etc.) and SMS(synthetic detergents), as well as alcohols, carboxylic acids , amines, etc.

Surfactant classification

- Ionic surfactants

- Cationic surfactants

- Anionic surfactants

- Amphoteric

- Nonionic surfactants

- Alkyl polyglucosides

- Alkylpolyethoxylates

Anionic surfactants

- contain one or more polar groups in the molecule and dissociate into aqueous solution with the formation of long-chain anions that determine their surface activity. These are the groups: COOH(M), OSO 2OH(M), SO3 H(M), where M is a metal (one-, two-, or trivalent). The hydrophobic part of the molecule is usually represented by saturated or unsaturated aliphatic chains or alkylaromatic radicals.In anionic surfactants, the cation can be not only a metal, but also an organic base. Often it is di- or triethanolamine. Surface activity begins to appear at the length of the hydrocarbon hydrophobic chain C 8 and increases with increasing chain length up to the complete loss of surfactant solubility in water. Depending on the structure of intermediate functional groups and the hydrophilicity of the polar part of the molecule, the length of the hydrocarbon part can reach up to C 18 .

Cationic surfactants

- dissociate in an aqueous solution to form a surface-active cation with a long hydrophobic chain and an anion (usually a halide, sometimes an anion of sulfuric or phosphoric acid).Among the cationic surfactants, nitrogen-containing compounds predominate; nitrogen-free substances are also used: compounds of sulfonium +X- and sulfoxonium +X-, phosphonium +X-, arsonium +X-, iodonium.

Cationic surfactants reduce surface tension less than anionic ones, but they chemically interact with the surface of the adsorbent, for example. with cellular proteins of bacteria, causing a bactericidal effect.

Ampholytic surfactants

– depending on the pH value, they exhibit the properties of cationic or anionic surfactants.They contain a hydrophilic radical and a hydrophobic part in the molecule, capable of being a proton acceptor or donor, depending on the pH of the solution. Typically, these surfactants include one or more basic and acidic groups, and may also contain a nonionic polyglycol group. At certain pH values, naz. isoelectric point, surfactants exist as zwitterions. The ionization constants of acidic and basic groups of truly soluble amphoteric surfactants are very low, but cation-oriented and anion-oriented zwitterions are most common. The cationic group is usually a primary, secondary or tertiary ammonium group, a pyridine or imidazoline residue. Instead of N m.b. atoms S, P, As, etc. Anionic groups are carboxyl, sulfonate, sulfoether or phosphate groups.

Nonionic PA

- high-molecular compounds that do not form ions in an aqueous solution.Their solubility is due to the presence of hydrophilic ether and hydroxyl groups in the molecules, most often the polyethylene glycol chain. When dissolved, hydrates are formed due to the formation hydrogen bond between the oxygen atoms of the polyethylene glycol residue and the water molecules. Due to the breakage of the hydrogen bond with increasing temperature, the solubility of nonionic surfactants decreases, so for them the cloud point is up. the temperature limit of micelle formation is an important indicator. Many compounds containing a mobile H atom (acids, alcohols, phenols, amines) react with ethylene oxide to form nonionic surfactants RO (C2H4O)nH. The polarity of one oxyethylene group is much less than the polarity of any acidic group in anionic surfactants. Therefore, to give the molecule the required hydrophilicity and HLB value, depending on the hydrophobic radical, from 7 to 50 oxyethylene groups are required. Feature nonionic surfactants - liquid state and low foaming in aqueous solutions.

Nonionic surfactants combine well with other surfactants and are often included in formulations.

Due to their detergent, wetting, emulsifying, dispersing and other valuable properties, surfactants are widely used in the production of detergents and cleaners, cosmetics and pharmaceuticals. latex, rubber. polymers, plant protection chemicals, textiles, leather and paper, building materials, corrosion inhibitors, in the extraction, transportation and processing of oil, etc. Most of the surfactants are used for the production of synthetic detergents (SMC).

Surfactants have relatively low toxicity to humans and animals. According to the degree of increase in toxicity, surfactants can be distributed in the following order: nonionic, anionic, cationic. When exposed to the skin and mucous membranes, synthetic surfactants can exhibit irritant and resorptive effects. It has been established that compositions of anionic and nonionic compounds have a less pronounced biological and toxic effect. Nonionic surfactants reduce the adsorption of anionic substances and only in large doses can have a damaging effect on the skin. The greatest danger of surfactants and preparations based on them for people lies in their sensitizing effect, the ability to cause allergic reactions. Sensitization can occur with any route of surfactant entry into the body.

Sources of surfactant entry into the aquatic environmentSurfactants enter water bodies in significant quantities with household (use of synthetic detergents in everyday life) and industrial sewage(textile, oil, chemical industry, production of synthetic rubber), as well as with runoff from agricultural land (included in insecticides, fungicides, herbicides and defoliants as emulsifiers).

The use of surface-active substances (surfactants)

Surfactants are widely used in industry, in agriculture, medicine and life. The world production of surfactants is growing every year, and the share of nonionic substances in the total output is constantly increasing. All types of surfactants are widely used in the production and use of synthetic polymers. The most important area of consumption of micelle-forming surfactants is the production of polymers by emulsion polymerization. The type and concentration of the selected surfactants (emulsifiers) largely determine the technological and physico-chemical properties of the resulting latexes. Surfactants are also used in suspension polymerization. Usually, high molecular weight surfactants are used - water-soluble polymers (volyvinyl alcohol, cellulose derivatives, vegetable adhesives, etc.). By mixing varnishes or liquid oil-and-resin compositions with water in the presence of emulsifiers, emulsions are obtained that are used in the manufacture of plastics, leather substitutes, non-woven materials, impregnated fabrics, water-borne paints, etc. High molecular weight water-soluble surfactants, in addition to being used in the above technological. processes, used as flocculants in various types of water treatment. With their help from sewage, as well as from drinking water remove contaminants in suspension.

The information was borrowed from the following sources:

1) www.wikipedia.org

3) www.hydrodynamictechnology.com

Nonionic surfactants

Compounds that dissolve in water without forming ions are called non-ionic. Their group is represented by polyglycol and polyglycol esters of fatty alcohols (for example, feystenside - Disodium Laurethsulfosuccinate - a fluid liquid consisting of citric acid and fatty alcohols). Non-ionic surfactants are obtained by oxyethylation of vegetable oils (castor, wheat germ, flax, sesame, cocoa, calendula, parsley, rice, St. John's wort). Non-ionic surfactants exist only in liquid or paste form, therefore they cannot be contained in solid detergents (soaps, powders).

Aqueous solutions esters fatty acids is a dispersion micellar solution often referred to as "smart soap" because it emulsifies dirt and grease, removing them from the surface of the skin and hair without damaging the protective mantle.

Properties of non-ionic surfactants

This type of surfactant makes the detergent soft, safe, environmentally friendly (biodegradability of non-ionic tensides is 100%). They stabilize soap suds, have mild thickening properties, have a bradykinase and polishing effect, restoring the outer layers of the epidermis and hair, and help to activate the action of therapeutic additives of the cleansing preparation.

This is the most promising and fastest developing class surfactant. At least 80-90% of these surfactants are obtained by adding ethylene oxide to alcohols, alkylphenols, carboxylic acids, amines, and other compounds with reactive hydrogen atoms. Polyoxyethylene ethers of alkylphenols are the most numerous and widespread group of nonionic surfactants, including more than a hundred trade names, the most well-known preparations are OP-4, OP-7 and OP-10. Typical raw materials are octyl-, ionyl- and dodecylphenols; cr. In addition, cresols, cresol acid, β-naphthol, etc. are used. If an individual alkylphenol is taken into the reaction, the finished product is a mixture of surfactants of the total f-ly RC6H4O (CH2O) mH, where m is the degree of oxyethylation, depending on the molar ratio of the initial components.

All surfactants. can be divided into two categories according to the type of systems they form when interacting with a dissolving medium. One category includes micelle-forming surfactants. in., to the other - not forming micelles. In solutions of micelle-forming surfactants c. above the critical micelle concentration (CMC), colloidal particles (micelles) appear, consisting of tens or hundreds of molecules (ions). Micelles reversibly decompose into individual molecules or ions upon dilution of a solution (more precisely, a colloidal dispersion) to a concentration below the CMC.

Thus, solutions of micelle-forming surfactants. occupy an intermediate position between true (molecular) and colloidal solutions, therefore they are often called semi-colloidal systems. Micellar surfactants include all detergents, emulsifiers, wetting agents, dispersants, etc.

Surface activity is conveniently assessed by the largest decrease in surface tension divided by the corresponding concentration - CMC in the case of micelle-forming surfactants. Surface activity is inversely proportional to CMC:

The formation of micelles occurs in a narrow range of concentrations, which becomes narrower and more defined as the hydrophobic radicals lengthen.

The simplest micelles of typical semi-colloidal surfactants, for example. fatty salts to - t, at concentrations not too exceeding CMC, have a spheroidal shape.

An increase in the surfactant concentration of anisometric micelles is accompanied by a sharp increase in the structural viscosity, leading in some cases to gelation, i.e. complete loss of fluidity.

action of detergents. Soap has been known for thousands of years, but it is only relatively recently that chemists have understood why it has detergent properties. The dirt removal mechanism is essentially the same for soap and synthetic detergents. Let's take it as an example of table salt, conventional soap, and sodium alkylbenzenesulfonate, one of the first synthetic detergents.

When dissolved in water salt dissociates into positively charged sodium ions and negatively charged chloride ions. Soap, i.e. sodium stearate (I), substances similar to it, as well as sodium alkylbenzenesulfonate (II) behave in a similar way: they form positively charged sodium ions, but their negative ions, unlike the chloride ion, consist of about fifty atoms.

Soap (I) can be represented by the formula Na+ and C17H35COO-, where 17 carbon atoms with hydrogen atoms attached to them are stretched out in a winding chain. Sodium alkylbenzenesulfonate (Na+ C12H25C6H4SO3-) has about the same number of carbon and hydrogen atoms. However, they are not located in the form of a winding chain, as in soap, but in the form of a branched structure. The significance of this difference will become clear later. For the washing action, it is important that the hydrocarbon part of the negative ion is insoluble in water. However, it is soluble in fats and oils, and it is thanks to fat that dirt sticks to things; and if the surface is completely free of grease, dirt does not linger on it.

The negative ions (anions) of soap and alkylbenzenesulfonate tend to concentrate at the interface between water and fat. The water soluble negative end remains in the water while the hydrocarbon portion is immersed in the fat. In order for the interface to be the largest, the fat must be present in the form of tiny droplets. As a result, an emulsion is formed - a suspension of droplets of fat (oil) in water (III).

If there is a film of fat on a solid surface, then upon contact with water containing detergent, the fat leaves the surface and passes into the water in the form of tiny droplets. Soap and alkylbenzenesulfonate anions are at one end in water and at the other end in fat. Dirt held by a film of grease is removed by rinsing. So in a simplified form, you can imagine the action of detergents.

Any substance that tends to collect at an oil-water interface is called a surfactant. All surfactants are emulsifiers because they promote the formation of an oil-in-water emulsion, i.e. "mixing" oil and water; all of them have detergent properties and form foam - after all, foam is like an emulsion of air bubbles in water. But not all of these properties are expressed in the same way. There are surfactants that lather profusely but are weak detergents; there are also those that almost do not foam, but are excellent detergents. Synthetic detergents are synthetic surfactants with particularly high detergency. In the industry, the term "synthetic detergent" generally means a composition including a surfactant, bleaches and other additives.

Soaps, alkylbenzenesulfonates and many other detergents, where exactly the anion dissolves in fats, are called anionic. There are also surfactants in which the cation is fat-soluble. They are called cationic. A typical cationic detergent, alkyldimethylbenzylammonium (IV) chloride is a quaternary ammonium salt containing nitrogen bonded to four groups. The chloride anion always remains in water, which is why it is called hydrophilic; hydrocarbon groups associated with a positively charged nitrogen are lipophilic. One of these groups, C14H29, is similar to the long hydrocarbon chain in soap and alkylbenzene sulfonate, but it is attached to the positive ion. Such substances are called "reverse soaps". Some of the cationic detergents have strong antimicrobial activity; they are used as part of detergents intended not only for washing, but also for disinfection. However, if they cause eye irritation, then when they are used in aerosol formulations, this circumstance should be reflected in the instructions on the label.

Another type of detergent is non-ionic detergents. The fat-soluble group in the detergent (V) is something like the fat-soluble groups in alkylbenzenesulfonates and soaps, and the remainder is a long chain containing many oxygen atoms and an OH group at the end, which are hydrophilic. Typically, non-ionic synthetic detergents exhibit high detergency but low lather.

Surfactants (Synthetic Surface Active Substances) are an extensive group of compounds, different in their structure, belonging to different classes. These substances are able to be adsorbed on the interface and consequently lower the surface energy (surface tension). Depending on the properties exhibited by surfactants when dissolved in water, they are divided into anionic substances (the active part is the anion), cationic (the active part of the molecules is the cation), ampholytic and non-ionic, which are not ionized at all.

It is no secret that the main active ingredients of washing powders are surface-active substances (surfactants). In truth, these active chemical compounds, getting into the body, destroy living cells by disrupting the most important biochemical processes.

The future of synthetics? Apparently yes. In confirmation of this, surfactants are being improved more and more, there are so-called non-ionic surfactants, the biodegradability of which reaches 100%. They are more efficient at low temperatures, which is important for gentle washing modes. Since many man-made fibers cannot withstand high temperatures. In addition, washing in more cold water saves energy resources, which is more relevant every day. Unfortunately, most non-ionic surfactants are liquid or pasty and are therefore used in liquid and pasty detergents. In powdered SMS, nonionic surfactants are introduced in the form of additives of 2-6% wt. Important advantages of synthetic surfactants are that they do not form calcium and magnesium salts that are poorly soluble in water. This means that they wash equally well in both soft and hard water. The concentration of synthetic detergents, even in soft water, can be much lower than soaps made from natural fats.

Probably, from household chemicals, we know the most synthetic detergents. In 1970, for the first time in the world, synthetic detergents (SMC) were produced more than ordinary natural soap. Every year its production is decreasing, while the production of SMS is continuously increasing.

For example, in our country, the dynamics of growth in the production of SMS can be displayed by the following data: in 1965 they were produced 106 thousand tons, in 1970 - 470 thousand tons, and in 1975 almost one million tons will be produced.

Why is the production of natural, sound soap, which faithfully served a person for many years, falling so much? It turns out he has a lot of flaws.

Firstly, soap, being a salt of a weak organic acid (more precisely, a salt formed by a mixture of three acids - palmitic, margaric and stearic) and a strong base - sodium hydroxide, hydrolyzes in water: xia (i.e. split by it) into acid and alkali. The acid reacts with hardness salts and forms new salts, already insoluble in water, which fall out in the form of a sticky white mass on clothes, hair, etc. This not very pleasant phenomenon is well known to anyone who has tried washing or bathing in hard water.

Another product of hydrolysis - alkali - destroys the skin (degreases it, leads to dryness and the formation of painful cracks) and reduces the strength of the fibers that make up various tissues. Polyamide fibers (kapron, nylon, perlon). are destroyed by soap especially intensively.

Secondly, soap is a relatively expensive product, since its production requires food raw materials - vegetable or animal fats.

There are other, less significant shortcomings of this until recently, completely indispensable substance in everyday life.

Unlike natural soaps, synthetic detergents have undoubted advantages: greater washing power, hygiene and economy.

About 500 names of synthetic detergents are now known on the international market, produced in the form of powders, granules, flakes, pastes, liquids.

The production of SMS gives a great economic effect. Experiments have shown that one ton of synthetic detergents replaces 1.8 tons of 40% laundry soap made from valuable food raw materials. It is estimated that one ton of CMS saves 750 kg of vegetable fats for the food industry.

The use of SMS in the household can reduce labor costs for hand and machine washing by 15-20% * At the same time, the strength and initial consumer properties of the fabric (whiteness, color brightness, elasticity) are much better than when using ordinary laundry soap.

It must be said that SMS is intended not only for washing clothes. There are special products for washing and cleaning various household items, synthetic toilet soaps, hair washing shampoos, foaming bath additives, into which biostimulants are introduced that have a tonic effect on the body.

The main component of all these products is a synthetic surfactant, the role of which is the same as that of an organic salt in ordinary soap.

However, chemists have long known that an individual substance, no matter how universal it may be, cannot satisfy all the requirements placed on it. Small additions of other accompanying substances help to find very useful qualities in this basic substance. That is why all modern SMS are not individual surfactants, but compositions that may include bleaches, fragrances, foam regulators, biologically active substances and other components.

The second most important component of modern synthetic detergents are condensed, or polymeric, phosphates (polyphosphates). These substances have useful properties: they form water-soluble complexes with metal ions present in water, which prevents the appearance of insoluble mineral salts that occur when washing with ordinary soap; increase the detergent activity of surfactants; prevent sedimentation of suspended particles of dirt on the washed surface; cheap to manufacture.

All these properties of polyphosphates make it possible to reduce the content of the more expensive main component, surfactant, in SMS.

As a rule, any synthetic detergent includes a fragrance - a substance with a pleasant smell, which is transferred to the laundry when using SMS.

Nearly all SMSs contain a substance called sodium carboxymethyl cellulose. It is a high molecular weight synthetic product, soluble in water. Its main purpose is to be, along with phosphates, an antiresorptive, i.e. prevent dirt from settling on already washed fibers.

Most of them have a number of advantages over soap, which has long been used for this purpose. So, for example, surfactants dissolve well and foam even in hard water. The potassium and magnesium salts formed in hard water do not worsen the washing action of surfactants and do not form a white coating on the hair.

The main active ingredients of all washing powders, the so-called. Surfactants (surfactants) are extremely active chemical compounds. Possessing some chemical affinity with certain components of human and animal cell membranes, surfactants, when ingested, accumulate on cell membranes, covering their surface with a thin layer and, at a certain concentration, can cause disturbances in the most important biochemical processes occurring in them, disrupt the function and integrity itself. cells.

In experiments on animals, scientists have found that surfactants significantly change the intensity of redox reactions, affect the activity of a number of important enzymes, and disrupt protein, carbohydrate and fat metabolism. Surfactant anions are especially aggressive in their actions. They can cause gross violations of the immune system, the development of allergies, damage to the brain, liver, kidneys, and lungs. This is one of the reasons Western European countries impose strict restrictions on the use of a-surfactants (anionic surfactants) in laundry detergent formulations. At best, their content should not exceed 2-7%. In the West, more than 10 years ago, they abandoned the use of powders containing phosphate additives in everyday life. In the German, Italian, Austrian, Dutch and Norwegian markets, only phosphate-free detergents are sold. In Germany, the use of phosphate powders is prohibited by federal law. In other countries, such as France, Great Britain, Spain, in accordance with government decisions, the content of phosphates in SMS is strictly regulated (no more than 12%).

The presence of phosphate additives in powders leads to a significant increase in the toxic properties of a-surfactants. On the one hand, these additives create conditions for more intense penetration of a-surfactants through intact skin, promote enhanced degreasing of the skin, more active destruction of cell membranes, and sharply reduce the barrier function of the skin. Surfactants penetrate into the microvessels of the skin, are absorbed into the blood and distributed throughout the body. This leads to a change physical and chemical properties the blood itself and impaired immunity. A-surfactants have the ability to accumulate in organs. For example, 1.9% of the total amount of a-surfactants that got on unprotected skin settles in the brain, 0.6% in the liver, etc. They act like poisons: in the lungs they cause hyperemia, emphysema, in the liver they damage the function of cells, which leads to an increase in cholesterol and intensifies the phenomena of atherosclerosis in the vessels of the heart and brain, disrupts the transmission of nerve impulses in the central and peripheral nervous systems.

But this does not exhaust the harmful effects of phosphates - they are a great threat to our environment. Getting after washing along with sewage into water bodies, phosphates are taken to act as fertilizers. The "harvest" of algae in reservoirs begins to grow by leaps and bounds. Algae, decomposing, secrete into huge quantities methane, ammonia, hydrogen sulfide, which destroy all life in the water. Overgrowth of reservoirs and clogging of slowly flowing waters leads to gross violations of the ecosystems of reservoirs, deterioration of oxygen exchange in the hydrosphere and creates difficulties in providing the population with drinking water. It is also for this reason that many countries have legally banned the use of phosphate SMS.

The traditional disadvantage of surfactants is harshness, expressed in skin irritation, dryness and discomfort after using shampoo or shower gel.

The skin of the hands, in contact with active chemical solutions of washing powders, become the main conductor of the penetration of dangerous chemical agents into the human body. A-surfactants actively penetrate even through intact skin of the hands and, with the assistance of phosphates, enzymes and chlorine, intensively disinfect it. Restoration of normal fat content and moisture of the skin occurs no earlier than after 3-4 hours, and with repeated use due to the accumulation of the harmful effect, the lack of fatty skin coating is felt within two days. The barrier functions of the skin are reduced, and conditions are created for intensive penetration into the body of not only a-surfactants, but also any toxic compounds - bacteriological toxins, heavy metals etc. After several washes with phosphate powders, skin inflammations - dermatitis - often develop. The pipeline of pathological immune reactions is launched.