Carbon nanotubes (CNTs) are a promising material that is planned to be used in a wide range of industries - from the production of bicycles to microelectronics. However, even minimal damage to the atomic structure of CNTs leads to a drop in their strength by 50%. This calls into question the possibility of building a space elevator from a material based on carbon nanotubes.

10/16/2015, Andrey Barabash 29

A team of researchers from Stanford University may have made a scientific breakthrough that could change the lives of amputees. Scientists have developed an artificial skin substitute that can sense touch and transmit this information to the nervous system. This technology could be used to create futuristic prostheses that will be built into the human body. nervous system. In addition, this technology will allow people not only to feel touch, but also to determine their strength.

The third state of carbon (except diamond and graphite) is revolutionizing the world of new technologies.Here are excerpts from several articles (with links to them).

http://www.nsu.ru/materials/ssl/text/news/Physics/135.html

Many of the promising areas in materials science, nanotechnology, nanoelectronics, and applied chemistry have recently been associated with fullerenes, nanotubes, and other similar structures, which can be called the general term carbon frame structures. What is it?

Carbon frame structures are large (and sometimes gigantic!) molecules consisting exclusively of carbon atoms. One can even say that carbon framework structures are a new allotropic form of carbon (in addition to the long-known ones: diamond and graphite). main feature of these molecules - this is their skeletal form: they look like closed, empty inside the "shell".

Finally, the variety of applications that have already been devised for nanotubes is striking. The first thing that suggests itself is the use of nanotubes as very strong microscopic rods and threads. As the results of experiments and numerical simulations show, the Young's modulus of a single-layer nanotube reaches values of the order of 1-5 TPa, which is an order of magnitude greater than that of steel! True, at present, the maximum length of nanotubes is tens and hundreds of microns - which, of course, is very large on an atomic scale, but too small for everyday use. However, the length of nanotubes obtained in the laboratory is gradually increasing - now scientists have already come close to the millimeter limit: see the work, which describes the synthesis of a multilayer nanotube 2 mm long. Therefore, there is every reason to hope that in the near future, scientists will learn how to grow nanotubes that are centimeters and even meters long! Of course, this will greatly affect future technologies: after all, a “cable” as thick as a human hair, capable of holding a load of hundreds of kilograms, will find countless applications.

The unusual electrical properties of nanotubes will make them one of the main materials of nanoelectronics. Prototypes of field-effect transistors based on a single nanotube have already been created: by applying a blocking voltage of several volts, scientists have learned to change the conductivity of single-layer nanotubes by 5 orders of magnitude!

Several applications of nanotubes in the computer industry have already been developed. For example, prototypes of thin flat displays based on a nanotube matrix have been created and tested. Under the action of a voltage applied to one end of the nanotube, electrons begin to be emitted from the other end, which fall on the phosphorescent screen and cause the pixel to glow. The resulting image grain will be fantastically small: on the order of a micron!

http://brd.dorms.spbu.ru/nanotech/print.php?sid=44

An attempt to photograph nanotubes using a conventional camera with a flash led to the fact that the block of nanotubes emitted a loud pop in the light of the flash and, flashing brightly, exploded.

The dumbfounded scientists claim that the unexpectedly discovered phenomenon of "explosiveness" of tubes can find new, completely unexpected uses for this material - up to and including use as detonators to undermine warheads. And also, obviously, it will call into question or make it difficult to use them in certain areas.

http://www.sciteclibrary.com/rus/catalog/pages/2654.html

Opens the prospect of significantly extending the life of rechargeable batteries

http://vivovoco.nns.ru/VV/JOURNAL/VRAN/SESSION/NANO1.HTM

Carbon nanotube structures - new material for emission electronics.

http://www.gazetangn.narod.ru/archive/ngn0221/space.html

Back in 1996, it was discovered that individual carbon nanotubes can spontaneously twist into cords of 100-500 fiber-tubules, and the strength of these cords turned out to be greater than that of diamond. More precisely, they are 10-12 times stronger and 6 times lighter than steel. Just imagine: a thread with a diameter of 1 millimeter could withstand a 20-ton load, hundreds of billions of times greater than its own weight! It is from such threads that you can get heavy-duty cables of great length. From equally light and durable materials, it is possible to build an elevator frame - a giant tower three times the diameter of the Earth. Passenger and cargo cabins will go along it at tremendous speed - thanks to superconducting magnets, which, again, will be suspended on carbon nanotube ropes. The colossal cargo flow into space will allow the active exploration of other planets to begin.

If someone is interested in this project, details (in Russian) can be found, for example, on the site http://private.peterlink.ru/geogod/space/future.htm. Only there is not a word about carbon tubes.

And on http://www.eunet.lv/library/win/KLARK/fontany.txt you can read Arthur Clarke's novel "Fountains of Paradise", which he himself considered his best work.

http://www.inauka.ru/science/28-08-01/article4805

According to experts, nanotechnology will make it possible by 2007 to create microprocessors that will contain about 1 billion transistors and will be able to operate at a frequency of up to 20 gigahertz with a supply voltage of less than 1 volt.

nanotube transistor

Created the first transistor, consisting entirely of carbon nanotubes. This opens up the prospect of replacing conventional silicon chips with faster, cheaper, and smaller components.

The world's first nanotube transistor is a Y-vol nanotube different shapes, which behaves like a familiar transistor - the potential applied to one of the "legs" allows you to control the passage of current between the other two. At the same time, the current-voltage characteristic of the “nanotube transistor” is almost ideal: current either flows or not.

http://www.pool.kiev.ua/clients/poolhome.nsf/0/a95ad844a57c1236c2256bc6003dfba8?OpenDocument

According to an article published May 20 in the scientific journal Applied Physics Letters, IBM specialists have improved carbon nanotube transistors. As a result of experiments with various molecular structures, the researchers were able to achieve the highest conductivity to date for carbon nanotube transistors. The higher the conductivity, the faster the transistor works and the more powerful integrated circuits can be built based on it. In addition, the researchers found that the conductivity of carbon nanotube transistors is more than double that of the fastest silicon transistors of the same size.

http://kv.by/index2003323401.htm

A group of professor at the University of California at Berkeley Alex Zettl (Alex Zettl) made another breakthrough in the field of nanotechnology. Scientists have created the first smallest nanoscale motor based on multi-walled nanotubes, as reported in Nature on July 24. The carbon nanotube acts as a kind of axis on which the rotor is mounted. The maximum dimensions of a nanomotor are about 500 nm, the rotor has a length of 100 to 300 nm, but the nanotube-axis has a diameter of only a few atoms, i.e. about 5-10 nm.

http://www.computerra.ru/hitech/tech/26393/

The Boston-based company Nantero has recently announced the development of a fundamentally new type of memory cards based on nanotechnology. Nantero Inc. actively engaged in the development of new technologies, in particular, pays considerable attention to finding ways to create non-volatile random access memory (RAM) based on carbon nanotubes. In his speech, a company representative announced that they are one step away from creating 10 GB memory boards. Due to the fact that the structure of the device is based on nanotubes, it is proposed to call the new memory NRAM (Nonvolatile (non-volatile) RAM).

http://www.ixs.nm.ru/nan0.htm

One of the results of the study was the practical use of the outstanding properties of nanotubes to measure the mass of extremely small particles. When a particle to be weighed is placed at the end of the nanotube, the resonant frequency decreases. If the nanotube is calibrated (i.e., its elasticity is known), it is possible to determine the mass of the particle from the shift of the resonant frequency.

http://www.mediacenter.ru/a74.phtml

Among the first commercial applications will be the addition of nanotubes to paints or plastics to make these materials electrically conductive. This will allow replacing metal parts with polymer ones in some products.

Carbon nanotubes are an expensive material. Now CNI sells it for $500 per gram. In addition, the technology for cleaning carbon nanotubes - separating good tubes from bad ones - and the method of introducing nanotubes into other products need to be improved. Some challenges may require a Nobel-level discovery, says Joshua Wolf, managing partner at nanotechnology venture firm Lux Capital.

Researchers became interested in carbon nanotubes because of their electrical conductivity, which turned out to be higher than that of all known conductors. They also have excellent thermal conductivity, chemical stability, extreme mechanical strength (up to 1,000 times stronger than steel) and, most surprisingly, semiconducting properties when twisted or bent. To work, they are given the shape of a ring. The electronic properties of carbon nanotubes can be similar to those of metals or semiconductors (depending on the orientation of the carbon polygons relative to the axis of the tube), i.e. depend on their size and shape.

http://www.ci.ru/inform09_01/p04predel.htm

Metallic conductive nanotubes can withstand current densities 102-103 times higher than conventional metals, and semiconductor nanotubes can be electrically turned on and off by means of a field generated by an electrode, allowing the creation of FETs.

IBM scientists have developed a method called "constructive destruction" that allowed them to destroy all metal nanotubes while leaving the semiconductor ones intact.

http://www.pr.kg/articles/n0111/19-sci.htm

Carbon nanotubes have found another use in the fight for human health - this time, Chinese scientists have used nanotubes to clean drinking water from lead.

http://www.scientific.ru/journal/news/n030102.html

We regularly write about carbon nanotubes, but in fact there are other types of nanotubes, obtained from various semiconductor materials. Scientists can grow nanotubes with exactly the right wall thickness, diameter, and length.

Nanotubes can be used as nanopipes for transporting liquids, they can also act as syringe tips with a precisely calibrated amount of nanodroplets. Nanotubes can be used as nanodrills, nanotweezers, tips for scanning tunneling microscopes. Nanotubes with sufficiently thick walls and small diameters can serve as supporting supports for nanoobjects, while nanotubes with large diameters and thin walls can serve as nanocontainers and nanocapsules. Nanotubes made from silicon-based compounds, including silicon carbide, are especially good for making mechanical products because these materials are strong and elastic. Also, solid-state nanotubes can be used in electronics.

http://www.compulenta.ru/2003/5/12/39363/

The research division of the IBM Corporation announced an important achievement in the field of nanotechnology. IBM Research specialists have managed to make carbon nanotubes glow - an extremely promising material that underlies many nanotechnological developments around the world.

The light-emitting nanotube is only 1.4 nm in diameter, 50,000 times thinner than a human hair. It is the smallest solid-state light-emitting device ever made. Its creation was the result of a program to study the electrical properties of carbon nanotubes, conducted at IBM over the past few years.

http://bunburyodo.narod.ru/chem/solom.htm

In addition to the creation of metal nanowires already mentioned above, which is still far from being implemented, the development of so-called cold emitters on nanotubes is popular. Cold emitters are a key element of the flat-panel TV of the future, they replace the hot emitters of modern cathode ray tubes, and also allow you to get rid of the gigantic and unsafe overclocking voltages of 20-30 kV. At room temperature, nanotubes are capable of emitting electrons, producing a current of the same density as a standard tungsten anode at almost a thousand degrees, and even at a voltage of only 500 V. (And X-rays require tens of kilovolts and a temperature of 1500 degrees (nan))

http://www.pereplet.ru/obrazovanie/stsoros/742.html

High values of the modulus of elasticity of carbon nanotubes make it possible to create composite materials that provide high strength at ultrahigh elastic deformations. From such material it will be possible to make ultra-light and heavy-duty fabrics for clothing for firefighters and astronauts.

For many technological applications, the high specific surface area of the nanotube material is attractive. During growth, randomly oriented helical nanotubes are formed, which leads to the formation of a significant number of nanometer-sized cavities and voids. As a result, the specific surface area of the nanotube material reaches values of about 600 m2/g. Such a high specific surface opens up the possibility of their use in filters and other devices of chemical technology.

http://www.1september.ru/ru/him/2001/09/no09_1.htm

A nanocable from the Earth to the Moon from a single tube could be wound on a reel the size of a poppy seed.

In terms of strength, nanotubes are 50-100 times stronger than steel (although nanotubes are six times less dense). Young's modulus - a characteristic of a material's resistance to axial tension and compression - is on average twice as high for nanotubes as for carbon fibers. The tubes are not only strong, but also flexible, and in their behavior do not resemble brittle straws, but hard rubber tubes.

A filament with a diameter of 1 mm, consisting of nanotubes, could withstand a load of 20 tons, which is several hundred billion times its own mass.

An international group of scientists has shown that nanotubes can be used to create artificial muscles, which, with the same volume, can be three times stronger than biological ones, are not afraid of high temperatures, vacuum, and many chemical reagents.

Nanotubes are an ideal material for the safe storage of gases in internal cavities. First of all, this applies to hydrogen, which would have been used long ago as a fuel for cars, if bulky, thick-walled, heavy and unsafe for pushing hydrogen storage cylinders did not deprive hydrogen of its main advantage - a large amount of energy and released per unit mass ( only about 3 kg of H2 is required per 500 km of a car run). It would be possible to fill the "gas tank" with nanotubes stationary under pressure, and extract the fuel - by slightly heating the "gas tank". In order to surpass ordinary gas cylinders in terms of mass and volume density of stored energy and (mass of hydrogen related to its mass together with the shell or to its volume together with the shell), nanotubes with relatively large diameter cavities - more than 2-3 nm are needed.

Biologists have managed to introduce small proteins and DNA molecules into the cavity of nanotubes. This is both a method for obtaining catalysts of a new type and, in the long term, a method for delivering biologically active molecules and drugs to various organs.

Stronger than a radial tire? All indications are that the advent of TUBALL carbon nanotubes in the tire industry will revolutionize even more than the advent of silicon in the 1990s, comparable to the discovery of the radial tire after the war. Even a small number of these amazingly small tubes with a diameter of one nanometer (1 billionth of a meter), with walls as thin as one (!) carbon atom, can improve the performance of any rubber. on an incredible scale. The history of this invention, born in the very heart of Siberia, is both grandiose and original.

In 1945, for the first time in history, a nuclear bomb was used. It was then that people learned that matter is a storehouse of enormous energy. At that stage, the main difficulty was - proper energy extraction. It is the need to work with carbon nanotubes at the atomic level that makes them both unusual in their characteristics and difficult to synthesize.

Not to die like an idiot...

Starting to look at such advanced technologies with a minimum of knowledge is a guarantee that you will not understand anything in this study, even if you think you know what carbon is. Probably more than 500,000 years ago, our ancestors began to use it for heating or cooking on charcoal. Approximately 3 centuries ago, the beginning of the use of coal (stone) and the steam engine marked the beginning of the era of industry. However, this prehistoric period in the history of carbon has nothing to do with modern nanochemistry...

In a broad sense, everything that grows and lives on earth depends on carbon. And a person who is 65% water, 3% nitrogen, 18% carbon and 10% hydrogen is a perfect example of this. In nature, there are more than a million compounds from a combination of carbon and hydrogen, and we should not forget that after coal, the main source of energy for us is hydrocarbons: in general, it is not so easy to do without irreplaceable carbon.

In its natural state, it has only two crystalline and very different forms: diamond and graphite. The first is a prestigious, extremely rare and hard material, the second is greasy to the touch, a much less exclusive type of carbon, mined in the amount of about one and a half million tons per year. Few people know that a diamond over time (a very long period!) breaks down into graphite, which is ultimately the most stable form of carbon. We are well acquainted with this black or gray mineral, it is worth remembering, for example, Chinese ink or pencil lead. Today, among other things, graphite helps to ensure the safety of nuclear power plants, and also gives us millions of electric batteries. It is he who is the indisputable ancestor of all forms of structures from carbon atoms, which a person will subsequently create.

From micrometer...

Such useful lubricating properties of graphite, resembling carbon "yarrow" or "thousand-layer" in its structure, are due to the ease with which the layers slide over each other. These flat and extremely thin layers resemble "honeycombs" in their shape, which consist of closely adjacent hexagonal rings, the top of each of which is a carbon atom bonded to its three neighbors. There are even layers one atom thick! Such a special structure facilitates (everything is relative!) access to carbon atoms. The huge potential of graphite has long been known, but the use of all the positive qualities of graphite is hindered by a number of problems that arise when working with graphite at the atomic level. The first pitfall is that it will be possible to clearly see such structures only after the advent of new powerful electron microscopes with high resolution.

Initially, chemists viewed carbon through the prism of the ease with which it turns into fiber. When connecting long and flat microcrystals and aligning them along parallel lines, it is possible to synthesize fibers with a diameter of 5-10 microns. Assembly of 1, 3, 6, 12, 24, 48 thousand of these carbon fibers depending on the type of use for which they were intended,

helps to synthesize surprisingly strong threads, despite their weightlessness. In an effort to restore the textile industry, which had suffered during the war, since 1959 the Japanese have been developing carbon fiber. The first research center would later become Toray, which is still one of the world's largest companies.

A brief overview of the exceptional qualities of single-walled nanotubes: conductive properties are better than copper, while they are five times lighter and 100 times stronger than steel, their length is a million times their diameter, and 1 gram of developed surface covers the area of 2 basketball courts!

A brief overview of the exceptional qualities of single-walled nanotubes: conductive properties are better than copper, while they are five times lighter and 100 times stronger than steel, their length is a million times their diameter, and 1 gram of developed surface covers the area of 2 basketball courts!

These new fibers were not entirely useful for traditional textiles, but given their exceptional mechanical properties, they were quickly appreciated by the military and aviation industries. Today, the latest generation of civil aircraft is made up of more than 50% carbon fiber, and the A380 would not be able to fly at all without it... And everywhere that efficiency and light weight are required - sporting goods, sailboats and racing cars, prosthetics, etc. .d. You can no longer do without carbon fiber.

...to nanometer

However, we had to wait until 1985, when man created the 3rd crystalline form of carbon, this time completely artificial, fullerenes. The scale changes drastically and immersion into the depths of infinitely small quantities begins, the micron of the fiber is replaced by the nanometer. The prefix "nano" ("nein" in Greek) means 1 billionth of a meter. When you play with atoms on the nanometer scale, you have to divide the micron dimension by 1,000! The discovery of fullerenes took place in the laboratory, when astrophysicists tried to find an answer to the question about the nature of the origin of long carbon-containing chains found in space.

Based on their knowledge of molecules confined to two-dimensional flat layers of graphite, chemists have been able to create new 3-D molecules that are still 100% carbon, but take on more diverse and interesting shapes: spheres, ellipsoids, tubes, rings, etc. d. What was the creation method used for this? Evaporation in a neutral environment of a graphite disk by means of laser ablation under very specific conditions. The idea itself, as well as its implementation, is far from being within the power of everyone ... Which was officially recognized in 1996, when Nobel Prize in Chemistry, an Anglo-American team of inventors consisting of Kroto, Curl, Smalley. And it was fair.

The very first product obtained with this generation method originally had the shape of a soccer ball! Like the ball, the structure was broken into 20 hexagons, and just like graphite, it was connected to 12 pentagons. This structure, called C60, is only 0.7 nanometers thick and has an internal space of only one nanometer, which is 200 million times smaller than a real soccer ball! However, it is this feature associated with the Anglo-Saxon culture of the research team that will lead to the assignment of a very original name to the product. In honor of the architect Buckminster Fuller, the inventor of geodesic spheres, C60 was called "footballene" for some time, then became the first buckminsterfullerene, and later was reduced (fortunately!) to fullerene.

After the door to the creation of an innovative material was opened, the process began: numerous research groups rushed to obtain fullerenes, inventing various methods for its synthesis. The most diverse forms of fullerene began to appear, more effective than the previous ones, with qualities as different as they were outstanding! It is now believed that there are more than 250,000 types of fullerons (and this is not the end!), which can be useful in any industry: pharmaceuticals, cosmetics, electronics, photovoltaics, lubricants, etc. After money, nanoparticles are the most used things in the world.

And then there are nanotubes and, finally, graphene.

Following the C60, it was possible to get "footballs" of 70, 76, 84, 100, 200 atoms, and even 20, and this was just the beginning. Under the influence of temperature, carbon molecules are divided (one has only to learn how to do this), and their constituent atoms are reunited in an endless variety of forms, and it seems that any configurations are possible. Balls, megatubes, nanotubes, dimers, polymers, nanoonions, etc., the huge family of fullerenes is constantly growing, but small nanotubes remain the main hope for serious industrial development.

If 1959 and 1985 are generally accepted dates for the birth of carbon fiber and fullerenes, then nanotubes appeared somewhere between 1991 and 1993. In 1991, the Japanese pioneer Sumio Iijima (NEC) obtained the first multilayer nanotubes during his fullerene synthesis research, the number of graphene layers in which ranged from 2 to 50. He re-obtains them in 1993, but now they are nanotubes with one wall, and at the same time Donald S. Bethune, IBM (Donald S. Bethune), each in his own way.

At this stage modern history carbon, a material appears that forms the walls of a single-walled nanotube (single wall), that is, graphene. This is the famous two-dimensional crystal, with a flat layer in the form of a honeycomb and only one atom thick, the layering of which forms graphite. In fact, what seemed simple, given its natural origin, was not, so we had to wait for 2004, when the Dutchman André Geim was able to isolate this carpet (or rather a grid?) One atom thick in one original way. He used duct tape to peel off matter layer by layer until a layer was 1 atom thick. Of course, other methods for obtaining graphene were also discovered, but for this Geim shared the Nobel in 2010 with Konstantin Novoselov, a Briton of Russian origin, who, like him, worked in the UK.

From a conventional point of view, in the future, graphene will revolutionize our lives. According to some, this is a technological upheaval comparable in scope to the transition from the Bronze Age to the Iron Age! Graphene, which is both flexible and elastic, conducts electricity better than copper. Colorless graphene is 6 times lighter than steel, and also 100 or even 300 times stronger. This unique one can do everything: despite his size, he can strengthen almost everything. It is 1 million times thinner than a hair - 3 million layers of graphene stacked together, no thicker than 1mm. However, the entire planet, starting with Europe, is spending billions to learn how to synthesize such layers to the right size at affordable prices. Unfortunately, not everyone has managed to achieve this yet!

Single wall nanotube

In the meantime, the launch of the serial synthesis of graphene has not been established, another form of fullerene with walls made of graphene has begun to gain momentum: a nanotube. Initially, Iijima (Iijima) received it using two graphite electrodes: when electricity creates a plasma of 6000° C: the anode (+) evaporates and a blackish deposit, i.e. nanotubes, forms on the cathode (-). In addition to this method of "arc discharge plasma sputtering", there are others: at high and medium temperature, in a gaseous state. The results are different, although, immediately after their release, the carbon atoms immediately begin to reunite, forming bizarre shapes. Thus, most of the synthesized nanotubes, as heirs of the fullerene family, are "closed" at the ends with one or two hemispherical caps. These "soccer halves" can be kept or removed to open both ends of the tube and fill it with other products to make it even more interesting.

Multiwalled nanotubes (MW, multiwall) resemble Russian nesting dolls in their structure: many tubes with decreasing diameter, twisted into each other, or one layer twisting around itself like a scroll. There are also gaps, holes in cellular or other structures with 5 or 7 sides, and sometimes impurities, deposits from metal catalysts, which are indispensable in this operation: then, before using such nanotubes, they need to be purified or restored. Single wall (SW, single wall) can also have a very different structure (spiral or not), which gives them a great advantage in terms of mechanical or electrical characteristics and gives them the properties of a conductor or semiconductor, etc.

Mastering the method of nanotube synthesis is not a journey along a long and calm river, but an extremely complex process, which consists in working with a very small amount of material at a high level of costs. There are still quite a number of difficulties, and it is still very difficult to get around them. This was revealed in 2013, when the chemical giant Bayer lost a lot of money by closing, just three years after opening, its plant in Leverkusen for the synthesis of 200 tons of nanotubes in year. It seems that this decision was driven by technical (carbon fiber and Kevlar are still in the ranks) and commercial competition, as well as a reassessment of demand, both in terms of its volume and growth rates.

OCSiAl, child of the silicone taiga

Like many great modern inventions with numerous creators, the discovery of nanotubes is not only due to Iijima and Bethune. Many teams worked on this issue, sometimes they were not even familiar with each other and used different methods. A more careful study of the history of the issue indicates that in 1952, Soviet scientists Radushkevich and Lukyanovich were already conducting research on tubes measuring 50 nanometers, and in 1976 Oberlin, Endo and Koyama studied hollow fibers and single-walled carbon nanotubes (single wall nano carbon tubes, abbreviated SWCNT). In 1981, Soviet scientists obtained an image of curling graphene, single-walled tubes in the range from 0.6 to 6 nm.

The Cold War and the protection of industrial secrets slowed down the dissemination of information about nanotubes, which explains the appearance on the world market of the Russian company OCSiAl, located in Akademgorodok, research city 20 km from Novosibirsk, in the heart of Siberia. It was conceived and created in 1957 by Academician Lavrentiev, Doctor of Physical and Mathematical Sciences. Nikita Khrushchev patronized the creation of the best conditions for the life and work of the elite Soviet science. Abandoned due to the collapse of the USSR, Akademgorodok was revived later in a new, more modern and capitalist form. This city of 60,000 inhabitants is today home to world-class startups. In 2006, a new technopark was created in it. Dynamics, creativity and a high concentration of advanced enterprises allow us to call Akademgorodok "Silicon Taiga" - by analogy with the Silicon Valley of California...

The very name OCSiAl is a hint at the chemical symbols of the main elements with which the company works: O - oxygen, C6 - carbon with its atomic number 6, Si - silicon, Al - aluminum.

Three Musketeers OCSiAl

As tradition requires, there were four Musketeers of the founders of OCSiAl! Even if officially Mikhail Predtechensky is only a Senior Vice President, the author of the synthesis technology, he is still key person companies and people of the future. It was this scientist and inventor who was able to finalize a “plasma-chemical” reactor capable of synthesizing single-walled carbon nanotubes of the highest quality in large volumes, and, therefore, at market prices, which no one has yet been able to do. This scientist, the bearer of the most advanced technology, was joined by three other co-founders, financiers and managers of the same high level: Yuri Igorevich Koropachinsky, Oleg Igorevich Kirilov and now living in Israel Yuri Zelvensky. They were able to identify the potential of the world market (estimated at 3 billion dollars!) and raise the 350 million dollars required to found OCSiAl in 2009, and then in 2013 registered patents and built the Graphetron 1.0 reactor, capable of synthesizing 10 tons of single-walled carbon nanotubes per year.

Graphetron 1.0 was put into circulation in 2014. And in 2016, the company already had 260 people on its staff, of which 100 people are scientists of the highest level working in the laboratories of Akademgorodok. The rest of the company's staff are engineers and merchants who sell branded nanotubes under the TUBALL trademark around the world. Initially, offices were opened in Columbus, Incheon, Mumbai, Shenzhen, Hong Kong, Moscow to enter all major markets. The company headquarters is located in Luxembourg. The team consists of specialists from a wide variety of profiles, since there are a large number of industries (and very diverse ones) whose products can “stimulate” TUBALL. Technical and commercial specialists are confident in the quality and wide range of possibilities for using TUBALL. Marketing OCSiAl sets a fairly high target bar for them. In 2017, it is planned to launch a second reactor capable of synthesizing 50 tons per year. Short-term projections are exponential based on 800 tons in 2020 and 3,000 tons in 2022.

And if the first two graphetrons begin to synthesize 60 tons each in Akademgorodok from 2018, then the third should, in theory, appear closer to Europe and its main markets. And since according to the main specifications requires "a lot of energy and gas", bets are already being made about the future location: why not in Luxembourg, since the company's headquarters are located here?

Clear Superiority

One could consider such forecasts too optimistic and be afraid to fly into the pipe, as happened with Bayer, but no one in Luxembourg is afraid of this - TUBALL single-walled carbon nanotubes are so superior in their characteristics to multilayer nanotubes. This is what Christoph Siara, Director of Marketing and Sales, Ocsial Europe, and Jean-Nicolas Helt, Lead Development and Customer Support, Elastomers, OCSiAl Europe, are convinced of. You can't tell by the name of Christophe Ciara that he is German. Christoph was educated as a lawyer. Living in France since 1983, career transitions from one cutting-edge industry to another have given him the experience to master the most complex technologies with understanding. When Christophe Ciara talks about nanotubes, he can be mistaken for a real chemist. Engineer Jean-Nicolas Elt is from France. He graduated in environmental physics from the University of Nancy, then from the ESEM of Orléans. Thanks to his excellent education, he was able to join Goodyear in Luxembourg. In 17 years of operation, he boasts several major achievements in the tire industry for heavy trucks and passenger cars. In 2015, he joined OCSiAl as a project manager, and it was he who said that TUBALL nanotubes could bring something valuable to the tire industry.

Christophe Ciara explains that the introduction of TUBALL single-walled carbon nanotubes is a significant breakthrough for the industry when compared to their predecessors, multi-walled nanotubes. With their diameters ranging from 25 to 40 nm, consisting of several twisted layers, these multilayer nanotubes are quite rigid in nature, which has had a negative impact on their mechanical properties. Unlike multi-walled nanotubes, TUBALL single-walled carbon nanotubes are thin, on the order of 1.5 nm, and very long > 5 microns: “They are 3,000 times longer than wide, which becomes clearer with this example: this is your garden irrigation hose 100 meters long!

This means that there is also the linguistic side of the issue, because the names "serpentine", "noodles", "hollow and long carbon fiber" look much more suitable than a tube. But still, a nanotube is much simpler!

Other aspects in which TUBALL has no rivals: its 1 nm thick layer is absolutely even, amorphous carbon< 10 %, остаточные неорганические примеси (Fer) < 15 % заключены в капсулах, то есть не действуют. В отличие от своих конкурентов TUBALL не требует никакой очистки. Кроме того к отличительным чертам нанотрубок TUBALL можно отнести: содержание углерода >85%, band ratio G/D (Raman spectrometry) > 70, which confirms excellent conductivity. All results are confirmed by independent laboratories, one of which is Intertek (May 2014).

Incredible growth and significant improvement in all parameters with synthetic nitrile rubber hermetic seals.

All the difference is in the process

Graphetron 1.0 Mikhail Predtechensky is probably one of those machines that will revolutionize the 21st century. It's about about a reactor capable of processing large volumes using precursors and inexpensive catalysts. How it works? This is an absolute secret, which is very well guarded. Christophe Ciara and Jean-Nicolas Helt laughingly assured that they did not know anything about this and never would. And the very first of all the papers for employment, which they signed, like all the staff, was a non-disclosure agreement! " Graphetron 1.0 » are going to show during scientific conference in November, but we bet it won't do us any good. But the most important thing is that it allows you to establish a continuous flow of synthesis of single-walled carbon nanotubes. High Quality reasonably priced. There is an estimate that these annual 10 tons represent today 90% of the world's synthesis of single-walled nanotubes. From 2017, the company plans to start synthesizing 50 tons more nanotubes!

Prices for TUBALL products? - It's forbidden to talk about it. Trade secret. Only now the company's brochures reveal it: there is a feeling that this is very far from the correct estimates, but at least it gives an idea of the approximate cost of nanotubes: shipping from Novosibirsk costs $8 per gram for a small order volume, $2 for large order. OCSiAl modestly assures that it has reduced the price by at least 25 times.

This frenetic race to increase production is due to the versatility of TUBALL. OCSiAl sells not just carbon nanotubes, but an almost universal additive capable of providing an explosive increase in the characteristics of approximately 70% of useful materials on our planet.

Versatile additive, incredible performance

Mentioning the properties of TUBALL is almost the same as doing splits: the further you dive into the depths that are visible only under a microscope, the higher you get to the heights of efficiency! Let's go through briefly: its thermal stability is maintained up to 1,000°C, it is 100 times stronger than steel, and its area exceeds any reasonable understanding: 1 gram of the developed surface of a TUBALL nanotube covers 2 basketball courts, that is, 3,000 m 2 .

All this would be of little use without one additional fundamental property - its amazing ability to disperse. Thanks to its very thin and long tubes, TUBALL creates numerous networks that blend invisibly with other elements and make them stronger. Thus, some ridiculous volume of TUBALL, from 1/1,000 to 1/10,000 of the total weight, is enough to give the characteristics of the material an explosive growth. The Single Walled Nanotube (SW) is the real SOLUTION for many of the technological breakthroughs of the 21st century.

A small bottle with 1 gram of TUBALL, which OCSiAl puts in the visitor's hand so that he can better "appreciate" the product, is a 100% success guarantee when they start talking about its contents in detail: 1015 pieces, that is, 1,000,000,000,000,000 ( one million billion) tubes! If they are put end to end to each other, then the resulting length will be approximately 50 million kilometers!

Everything that TUBALL is capable of, OCSiAl briefly presents in one diagram in the form of a beautiful flower with numerous petals. By choosing its properties, conductivity, strength, chemical neutrality, transparency, etc., or adding them together, one opens up a large number of possible applications. TUBALL is truly the "universal amp" it claims to be.

And to facilitate the use of a conductive additive, TUBALL nanotubes are rarely supplied in powder form. They are offered in much more convenient options for application: in the form of a liquid, polymer, oil, rubber, etc. even in the form of a suspension in solvents. This ensures ease of mixing and dispersion. For example, 50 grams of TUBALL nanotubes dissolved in 50 kg of epoxy or polyester immediately provide materials with conductivity, which is very practical for floors that can even be colored!

Flexibility - security

Ready-to-use concentrates have another advantage: ensuring safety when working with nanotubes. Their primary form and very small size allow them to enter the very heart of the cells of the human body, so precautions must be taken, even if carbon is not toxic to humans. The nanotubes introduced into the matrix cannot evaporate in the atmosphere, which makes their use safe and reassures those who are afraid of carcinogenic effects, like from asbestos. World Organization Health (WHO) suggests that nanotubes are similar to fibers. However, the characteristics of TUBALL single-walled carbon nanotubes are very different from those of multi-walled carbon nanotubes, which we mentioned at the very beginning. “To be completely clear,” sums up Christophe Ciara, “if MWCNTs are the golf club, TUBALL SWCNTs are the water hose. The solid shape and the presence of roughness allow MWCNTs to enter and attach to the cell. But at the same time, the rigid and inflexible shape of multi-walled nanotubes creates a number of problems that can be avoided by using flexible and long single-walled TUBALL nanotubes, which, due to their characteristics, do not penetrate into the cell itself.

OCSiAl is very attentive to the study of this problem, therefore, it follows all the research conducted in the world. In particular, since 2008 the company has overseen the work of the BAuA, a German government institute that develops industrial standards and, in particular, defines the characteristics of products that ensure the safety of workers. TUBALL was taken in its simplest form - in powder, which is bought by 10% of customers. Nanotubes have received positive results on the safety of their use for environment. There was only one problem: there was no way to clean the air of nanotubes through filtration, because, due to their too small size, they elude all materials known to us! In the meantime, a solution is being searched for (it is being worked on), OCSiAl does not forget the precautionary principle, proposing to use the most effective types of protection for the TUBALL powder form, which in themselves are already mandatory when working with the most dangerous chemicals: a mask that covers the entire face, overalls, gloves, boots. For the liquid composition of the substance, glasses, gloves and overalls are sufficient.

OCSiAl also cares about the integrity of the life cycle of its products. The news is encouraging, because once embedded in a matrix and then in new materials, nanotubes remain there. Having received every possible degree of protection against the danger they can carry, TUBALL nanotubes become a "normal" chemical agent that is subject to the most stringent regulations recently introduced. Thus, with pleasure, but without much surprise, OCSiAl received the REACH certificate in October, which allows it to supply up to 10 tons of nanotubes per year to the European market from now on.

The Great Tire Revolution

From the very beginning of tires, all manufacturers have been looking for technologies that could enhance the characteristics of the material. From additives such as clay and talc to carbon, we are still striving to improve tire durability. The advent of silicon in 1991 completely changed the situation on the market. Silicon allows rubber to be given universal proportions that adapt to specific loads. Silicon has become an essential ingredient for tire performance, but it's nothing compared to the dramatic leap that will come with TUBALL's entry into the tire industry.

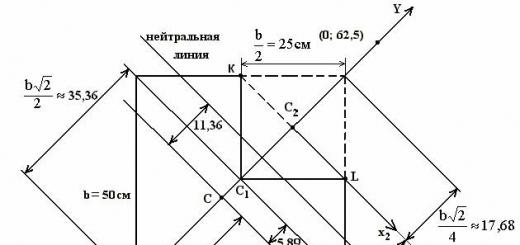

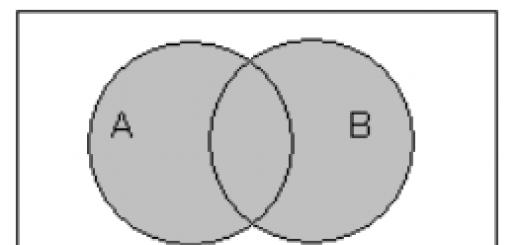

With over 17 years of experience at Goodyear under his belt, Jean-Nicolas Helt is heading straight to the point. The diagram on page 53 shows the dispersion of TUBALL in tire compounds. On the left, two black carbon particles appear to be quite isolated in the polymer cube. The central picture shows the results of strengthening the product using multi-walled carbon nanotubes - rather short, solid and packaged. Looking at the picture, you can see that the gain turned out to be quite weak and ineffective. On the right, TUBALL, at a ratio of only 1/1,000 to the total weight, fills the cube 100% with a very dense network of single-walled carbon nanotubes that are tightly intertwined with each other. Thus, this mini-filler has a great reinforcing effect due to the fact that it is highly structured and allows to increase the cohesion of the components. In any case, such reinforced connections have the best effect, allowing to reduce the mobility of components, and, therefore, their wear. It is quite logical that this A 3D network of single-wall carbon nanotubes forms a second skeleton in the tire's rubber to slow down tire wear. In addition, TUBALL is chemically neutral, making it more resistant to heat, UV and hydrocarbon contamination than other raw materials.

“Careful,” says Jean-Nicolas Elt, “TUBALL handles soot in the same way as silicon. The tire retains its basic characteristics, moreover, with the addition of even very small amounts of single-walled carbon nanotubes, the characteristics begin to improve significantly. Another advantage of TUBALL is thatthat it is an extremely strong conductor, so it is possible to make a bus tire 100% silicon, but still 100% static-conductive, instead of being insulated. This eliminates the need for a bead of NdC rubber at the equator of a premium tire tire to dissipate static electricity into the ground.” This is another significant gain.

Diagram A. The blue spiders represent the performance of the classic mixture, the pink areas show the gain that can be obtained by adding silicon. Circuits to be compared with the following circuit B, which addresses this issue with the addition of TUBALL.

Scheme B. The principle is the same as in the previous scheme A, the scale of values is the same. It can be concluded that pink surfaces showing performance improvement with the addition of TUBALL.

Polymers with the addition of TUBALL

TUBALL has the same effect on polymers as it does on reinforcing fillers. Thus, engineers can easily develop tires "a la carte", adding this or that polymer, maintaining this or that characteristic, which will not be worsened by the powerful development of other indicators. For example, the imperfections of some tires on dry or wet surfaces can be compensated for with TUBALL. And for motorcycle tires, it will also be a good option, as it will simultaneously improve grip and wear. “It can improve anything,” Jean-Nicolas Helt summarizes briefly. But what's the price? Given the negligible amount to add to the mix (a few thousandths of the total weight) and the reasonable cost of TUBALL, Jean-Nicolas Elt believes that the manufacturing cost will increase from $2 to $3 per tyre, which is comparatively expensive but bearable for premium tyres. , which should be the first to adopt TUBALL, because, for them, increasing efficiency is in the first place. And this is absolutely true, because big number manufacturers are already looking towards TUBALL, especially after receiving positive results from tests conducted in independent laboratories, for example, in the world's No. 1 laboratory Smithers. That's when all OCSiAl's claims were tested and confirmed, including the fact that exceeding the small amounts prescribed by TUBALL does not bring any improvement. “You don’t need to add more than you need,” is the conclusion!

The conclusion also states that dosing TUBALL for mixtures is very simple, since the process itself does not change (mixing, extrusion, boiling, etc.) and you only need to open the TUBALL tank to pour its contents into the Banbury mixer. OCSiAl supplies its TUBALL MATRIX 603 to the market already in the form of a ready-to-use concentrate - nanotubes mixed with synthesized rubbers (natural, styrene butadiene, nitrile butadiene, etc.) plus tridecyl alcohol ethoxylate (TDAE) process oil, which most often used for tires. TUBALL is also available as a suspension in huge number solvents (MEK, isopropanol, ethylene glycol, ethyl acetate, N-methylpyrrolidone, glycerin or even water). Ideal in terms of safety, these formulations are extremely easy to use.

Simple and perfect to use, this solution can be made even easier by adding TUBALL to the polymer at the time of its polymerization: no more additional steps during mixing! This method of injecting a polymer at the moment of birth "shifts" the problem from the manufacturer to the supplier of the synthesized rubber, but OCSiAl has already thought about this, having begun cooperation with LANXESS. In other words, TUBALL is preparing to enter the tire industry through two doors at once, which means that its advancement will go even faster.

Even if the addition of natural rubbers can only occur at the moment of mixing, the use of TUBALL will achieve chic prospects even if it is added directly during the manufacturing process to other synthesized rubbers, isoprene or nitrile butadiene. The latter made a real leap in the industry, moving to a new level of gasket strength in all areas ... Simply put, the market for tires, industrial rubber (latex surgeons' gloves switched to TUBALL), polymers, elastomers, composites, batteries, photovoltaics, flexible screens, magnetic inks, antistatic concrete, paints, ceramics, copper, semiconductors, stained glass, adhesive tapes, etc. are all target areas where TUBALL can be applied. And now we better understand all the prospects of the project " Graphetron 50" aimed at delivering an explosive performance boost for 70% of existing products in the industry...

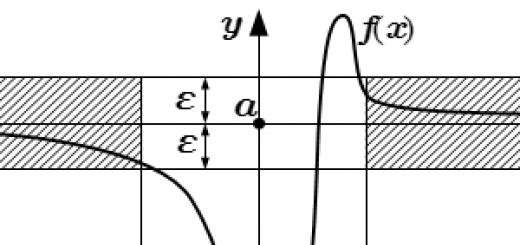

Scheme C. The straight line below is the classic compounds, the green dotted line is the mixtures with the addition of silicon, while the blue transverse line shows the improvement in tire performance with the addition of TUBALL.

Already competition...

For those who still have doubts about the advantages offered to tire manufacturers by using TUBALL, Jean-Nicolas Elt presents three schemes. The first two are classic "spiders" that compare the "efficiency" of three different types of tires - conventional, enhanced with silicon and tires with the addition of TUBALL. The first table (A) visualizes in the form of zones of light pink color, the breakthrough achieved through the use of silicon is certainly important, but still far from affecting the entire range of tire characteristics.

The second (B) is based on the same principle, but this time, the light pink TUBALL zones take up most of the area, showing a significant increase in performance in almost all parameters. Moreover, the low volumes of material used are surprising: 0.2% in natural rubber concentrate, 0.1% for the other two, in the form of oil concentrate.

The third scheme (C) has long been known in the specialized press. The two straight lines determine the characteristics of the "soot" mixtures (bottom, in dark blue) and the performance of "silicon", which are more effective, which are highlighted in green dotted lines. The third straight line, which runs clearly from above, visualizes mixtures with the addition of TUBALL - highlighted at the top blue color. The graph clearly shows the advantages provided by single-walled carbon nanotubes.

Some manufacturers are already ready to get ahead of the curve by announcing the use of nanocarbon. This does not mean that other manufacturers are no longer using nanocarbon, although they do not talk about it ... Since the beginning of the year, bicycle tire manufacturer Vittoria has been selling tires with the addition of graphene, the base material for TUBALL nanotubes (return to the beginning of the article if you have already forgotten! ). Vittoria uses it as layers embedded in the tire and claims to have found the hitherto unattainable compromise: improving rolling resistance while also achieving tire puncture resistance, a characteristic so important to cyclists. "Improve everything at once" - now the competition confirms the words of Jean-Nicolas Elta...

The second piece of news came from China, where Sentury Tire and Huago reached an agreement in August to make graphene-infused tires. We don't know how yet, but either way, the technology will be exactly different from the Vittoria tires. News like this indicates overall progress: rolling resistance and mileage times 1.5. And here are two representatives of the company showed their graphene "first-born" at a major meeting of carbon specialists "GrapChina" on September 22. At the same time and at the same meeting, the manufacturer Shangdong officially announced that it will now produce graphene-added tires. And all those who use it cite that it was invented Nobel laureates. This is an argument that TUBALL cannot claim, even if nanotubes were invented before graphene!

We bet that the amount of news of this kind will grow very quickly. 2016 marks the starting point for carbon in the tire industry. And this shift has just begun, and OCSiAl, with its nanotubes, is at the forefront of this transformation. And this is a process worthy of our attention... For many years to come...

Jean Pierre Gosselin

Single-walled carbon nanotubes were discovered in 1993. Two articles were published simultaneously in one issue of the journal Nature, in which researchers from Japan Ichihashi and Sumio Iijima, as well as scientists from IBM, published results on the possibility of synthesizing single-walled carbon nanotubes using metal catalysts. Carbon nanotubes are champions, champions among other materials.

Consider physical properties. Conductivity. The electrical conductivity of carbon nanotubes is much higher than that of copper and silver. In addition, ballistic conduction is observed at a distance of several micrometers. On the other hand, carbon nanotubes are a remarkable semiconductor material that can be compared with silicon in terms of its characteristics. Using single-walled carbon nanotubes, it is possible to obtain transistors in which the mobility of charge carriers significantly exceeds the mobility in traditional silicon transistors. In addition, single-walled nanotubes make it possible to obtain transistors on flexible and transparent substrates. Single-walled carbon nanotubes have remarkable thermal properties, better than those of diamond: thermal conductivity in tubes is about 2 times higher. In addition, single-walled carbon nanotubes are an efficient field emitter of cold electrons.

The thermal stability of carbon nanotubes is quite high: you can, without fear of destroying them, heat up to 1500 degrees Celsius, while their main competitor - organic conductors - begin to break down already at a temperature of about 150 degrees Celsius. Carbon nanotubes are very light material. On the other hand, they have a high specific strength - 25 times higher than that of high-strength steel. This is almost the only material from which it would be possible to create a space elevator, connecting a satellite rotating in geostationary orbit with the Earth, in the form of a cable, on which it would be possible to lift loads into space. The addition of carbon nanotubes to polymers makes it possible to obtain composites in which the mechanical properties change, and very strong composite materials are obtained, in which the electrical conductivity also varies. If the material is covered with a layer of carbon nanotubes, then a layer can be obtained that will protect and shield the material from electromagnetic waves.

What can be said about energy applications: carbon nanotubes can be used as an anode in lithium batteries, as supercapacitors, and, in addition, they are efficient elements in solar cells - on dyes, as well as on heterojunctions, where the silicon π-layer has been replaced single-walled nanotubes. In addition, it is possible to make various gas and optical sensors of a fairly wide spectral range from carbon nanotubes. Carbon nanotubes can be used as transparent electrodes and transistors. I would like to talk about this in a little more detail, but later.

I would like to talk about the conductivity of carbon nanotubes. As I said, single-walled carbon nanotubes are both a good metal conductor and a wonderful semiconductor. The type of conductivity is determined by the symmetry group. If we know the chirality indices, then we can predict the metallic properties of a carbon nanotube. If the difference between these indices is 0 or a multiple of 3, we get carbon nanotubes that have metallic properties, while all other nanotubes will be semiconductor. Obviously, 1/3 of carbon nanotubes are metallic and 2/3 are semiconductor. Unfortunately, none of the currently available methods makes it possible to synthesize carbon nanotubes with a certain chirality. What to say about chirality - it is impossible to obtain carbon nanotubes even with a certain metallicity.

According to the methods of carbon atomization, all methods for the synthesis of carbon nanotubes can be divided into physical and chemical. The physical method is based on the evaporation and sublimation of carbon. We know that graphite has a very low pressure. saturated vapors, therefore, in order to evaporate graphite, it must be heated to a temperature above 3000 kelvins. Solar energy, induction heating, laser ablation, or electric arc discharge can be used for this. This method was very popular in the early days of carbon nanotube research, but, unfortunately, high temperatures do not allow one to control the properties of the resulting material. Therefore, in recent years there has been a trend towards the study of single-walled carbon nanotubes - more precisely, the methods of their production - by chemical methods. This method is based on the decomposition of carbon compounds - these can be hydrocarbons, alcohols, ketones, any organic, carbon monoxide.

In its turn, chemical methods I would divide it into the synthesis of carbon nanotubes on substrates and in the gas phase. Synthesis of carbon nanotubes on substrates is the most common method. It allows you to get carbon nanotubes: you can take an inert substrate, form catalyst nanoparticles on it, place such a substrate in a reactor for a certain time (usually 5, 10, 20 or 30 minutes), and then enjoy the images obtained on your substrate in an electron microscope . On the other hand, the aerosol method is not based on the use of a substrate, and all processes of carbon nanotube formation occur in the gas phase. There is a serious time limit here, since about 10–12 seconds elapse between the input and output of steam into the reactor. During this time, everything should happen: the decomposition of the catalyst precursor (usually either iron pentacarbonyl or ferrocene is used in such methods), then the formation of nanometer-sized catalytic particles, from 1 to 5 nanometers, the decomposition or decomposition of carbon components on the catalyst surface and the growth of carbon nanotubes . Everything takes 12 seconds.

The aerosol method for studying carbon nanotubes was first proposed in 1999 at the University of Houston. I have also been involved in the synthesis of carbon nanotubes by the aerosol method for about 13 years. I believe that this method is the most promising of all, as it allows to obtain high-quality carbon nanotubes without unused catalytic particles, without amorphous carbon, that is, a product that is ready for widespread use when it leaves the reactor. After the reactor, carbon nanotubes are deposited on a filter. Then they can be transferred to any other substrate. This process takes literally a matter of seconds, but allows you to very quickly get high-quality transparent electrodes.

In our work, we have used carbon nanotubes in many areas, from filters to electronics. I will give a few examples. Aerosol filters. Through a film of carbon nanotubes, a gas stream containing aerosol particles that we want to get rid of passes quite easily without creating resistance. In addition, nanopores make it possible to filter almost all objects. We measured the characteristics of such a filter and found that the quality factor of filters made from single-walled carbon nanotubes is an order of magnitude higher than that of commercially available analogues. In addition, we used carbon nanotubes as electrochemical sensors - standard dopamine tests allowed us to determine a sensitivity level of less than 100 millinanomoles over a fairly wide range - about 4 orders of magnitude in concentration. The carbon nanotube film is a remarkable laser absorber that allows one to obtain 200 femtosecond pulses. In addition, carbon nanotubes can be used as a flow meter, air heater, incandescent lamp and other devices. We have also created a thermoacoustic loudspeaker using freely suspended carbon nanotubes. In addition, transparent electrodes have excellent properties, which I believe will be on the market soon, because transparent electrodes based on single-walled carbon nanotubes have excellent characteristics, comparable to indium oxide doped with tin.

Single-walled carbon nanotubes can and will most likely be used in electronics as transparent electrodes. In English it is called ITO replacement- replacement of tin-doped indium oxide, this is the material that is used in 75% of mobile phones and gadgets. It is known that indium is a rare-earth material, in addition, tin-doped indium oxide is a rather brittle material that cannot be used for flexible and transparent electronics, while single-walled carbon nanotubes, more precisely films made of them, can be bent into several tens of thousands times with virtually no change in surface resistance. In addition, thin-film field-effect transistors can be made from our material, which have remarkable characteristics at the level of traditional silicon technologies, and sometimes even exceed them, with an on-to-off current ratio of 106 and 108 and with a charge carrier mobility of the order of 1000 or more square centimeters per volt. for a second.

The aerosol method for the synthesis of carbon nanotubes and the preparation of films deposited on a filter is a unique opportunity for the preparation of components for flexible and transparent electronics. Deposition occurs at room temperature, this technology does not require a vacuum, it is quite fast and cheap. Our goal is to create a large-scale production of carbon nanotubes with the possibility of using roll technology for use in flexible and transparent electronics.

Fullerenes and carbon nanotubes. Properties and application

In 1985 Robert Curl, Harold Kroto and Richard Smalley completely unexpectedly discovered a fundamentally new carbon compound - fullerene , whose unique properties have caused a flurry of research. In 1996, the discoverers of fullerenes were awarded the Nobel Prize.

The basis of the fullerene molecule is carbon- this unique chemical element, characterized by the ability to combine with most elements and form molecules of the most diverse composition and structure. From school course chemistry, you certainly know that carbon has two main allotropic states- graphite and diamond. So, with the discovery of fullerene, we can say that carbon acquired another allotropic state.

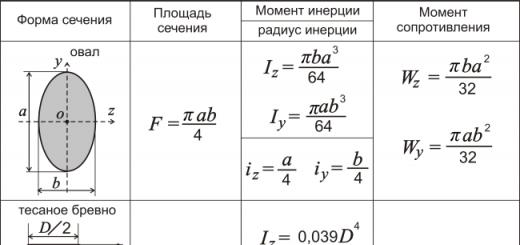

Let us first consider the structures of graphite, diamond, and fullerene molecules.

Graphitehas layered structure (Fig.8) . Each of its layers consists of carbon atoms covalently bonded to each other in regular hexagons.

Rice. 8. Structure of graphite

Neighboring layers are held together by weak van der Waals forces. Therefore, they easily slide over each other. An example of this is a simple pencil - when you run a graphite rod over paper, the layers gradually "peel" from each other, leaving a mark on it.

Diamondhas a three-dimensional tetrahedral structure (Fig.9). Each carbon atom is covalently bonded to four others. All atoms in the crystal lattice are located at the same distance (154 nm) from each other. Each of them is connected with others by a direct covalent bond and forms in a crystal, no matter what size it is, one giant macromolecule

Rice. 9. Diamond structure

Due to the high energy of C-C covalent bonds, diamond has the highest strength and is used not only as a precious stone, but also as a raw material for the manufacture of metal-cutting and grinding tools (perhaps readers have heard about diamond processing of various metals)

Fullerenesgot their name from the architect Buckminster Fuller, who designed these structures for use in architectural construction (which is why they are also called buckyballs). Fullerene has a frame structure, very reminiscent of a soccer ball, consisting of “patches” of 5 and 6-corner shapes. If we imagine that carbon atoms are located at the vertices of this polyhedron, then we will get the most stable C60 fullerene. (Fig. 10)

Rice. 10. Fullerene structure C60

In the C60 molecule, which is the most famous and also the most symmetrical representative of the fullerene family, the number of hexagons is 20. In this case, each pentagon borders only on hexagons, and each hexagon has three common sides with hexagons and three with pentagons.

The structure of the fullerene molecule is interesting in that a cavity is formed inside such a carbon "ball", into which, due to capillary properties it is possible to introduce atoms and molecules of other substances, which makes it possible, for example, to transport them safely.

As fullerenes were studied, their molecules were synthesized and studied, containing a different number of carbon atoms - from 36 to 540. (Fig. 11)

a B C)

Rice. 11. Structure of fullerenes a) 36, b) 96, c) 540

However, the diversity of carbon framework structures does not end there. In 1991, a Japanese professor Sumio Iijima discovered long carbon cylinders, called nanotubes .

Nanotube - This is a molecule of more than a million carbon atoms, which is a tube with a diameter of about a nanometer and a length of several tens of microns . In the walls of the tube, carbon atoms are located at the vertices of regular hexagons.

Rice. 13 Structure of a carbon nanotube.

a) general view of the nanotube

b) a nanotube torn at one end

The structure of nanotubes can be imagined as follows: we take a graphite plane, cut out a strip from it and "glue" it into a cylinder (in fact, of course, nanotubes grow in a completely different way). It would seem that it could be simpler - you take a graphite plane and turn it into a cylinder! - however, before the experimental discovery of nanotubes, none of the theorists predicted them. So scientists could only study them and be surprised.

And there was something to be surprised about - after all, these amazing nanotubes of 100 thousand.

times thinner than a human hair turned out to be an extremely durable material. Nanotubes are 50-100 times stronger than steel and have six times less density! Young's modulus - the level of resistance of the material to deformation - for nanotubes is twice as high as for conventional carbon fibers. That is, the tubes are not only strong, but also flexible, and in their behavior do not resemble brittle straws, but hard rubber tubes. Under the action of mechanical stresses exceeding the critical ones, nanotubes behave quite extravagantly: they do not "tear", do not "break", but simply rearrange!

Currently, the maximum length of nanotubes is tens and hundreds of microns - which, of course, is very large on an atomic scale, but too small for everyday use. However, the length of the resulting nanotubes is gradually increasing - now scientists have already come close to the centimeter line. Multilayer nanotubes 4 mm long have been obtained.

Nanotubes come in a variety of shapes: single-walled and multi-layered, straight and helical. In addition, they demonstrate a whole range of the most unexpected electrical, magnetic, and optical properties.

For example, depending on the specific folding scheme of the graphite plane ( chirality), nanotubes can be both conductors and semiconductors of electricity. The electronic properties of nanotubes can be purposefully changed by introducing atoms of other substances into the tubes.

Voids inside fullerenes and nanotubes have long attracted attention

scientists. Experiments have shown that if an atom of some substance is introduced into the fullerene (this process is called "intercalation", i.e. "introduction"), then this can change its electrical properties and even turn the insulator into a superconductor!

Is it possible to change the properties of nanotubes in the same way? It turns out yes. Scientists were able to place a whole chain of fullerenes with gadolinium atoms already embedded in them inside the nanotube. The electrical properties of such an unusual structure were very different from both the properties of a simple, hollow nanotube and the properties of a nanotube with empty fullerenes inside. It is interesting to note that special chemical designations. The structure described above is written as [email protected]@SWNT, which means "Gd inside C60 inside a Single Wall NanoTube (Single Wall NanoTube)".

Wires for macro devices based on nanotubes can pass current with little or no heat, and the current can reach a huge value - 10 7 A / cm 2 . A classical conductor at such values would instantly evaporate.

Several applications of nanotubes in the computer industry have also been developed. As early as 2006, flat-screen emission monitors based on a nanotube matrix will appear. Under the action of a voltage applied to one end of the nanotube, the other end begins to emit electrons that fall on the phosphorescent screen and cause the pixel to glow. The resulting image grain will be fantastically small: on the order of a micron!(These monitors are covered in the Peripherals course.)

Another example is the use of a nanotube as the tip of a scanning microscope. Usually such a point is a sharply sharpened tungsten needle, but by atomic standards such sharpening is still quite rough. A nanotube, on the other hand, is an ideal needle with a diameter of the order of several atoms. By applying a certain voltage, it is possible to pick up atoms and entire molecules located on the substrate directly under the needle, and transfer them from place to place.

The unusual electrical properties of nanotubes will make them one of the main materials of nanoelectronics. Prototypes of new elements for computers were made on their basis. These elements provide a reduction in devices compared to silicon devices by several orders of magnitude. Now the question of which direction the development of electronics will go after the possibilities of further miniaturization of electronic circuits based on traditional semiconductors are completely exhausted (this may happen in the next 5-6 years) is being actively discussed. And nanotubes are given an indisputably leading position among promising candidates for the place of silicon.

Another application of nanotubes in nanoelectronics is the creation of semiconductor heterostructures, i.e. metal/semiconductor structures or the junction of two different semiconductors (nanotransistors).

Now, for the manufacture of such a structure, it will not be necessary to grow two materials separately and then "weld" them together. All that is required is to create a structural defect in the nanotube during its growth (namely, to replace one of the carbon hexagons with a pentagon) by simply breaking it in the middle in a special way. Then one part of the nanotube will have metallic properties, and the other part will have the properties of semiconductors!