Ecologists public organization The Green Patrol visited the Moscow Oil Refinery and took wastewater samples, which were sent for analysis to an independent state chemical laboratory. Already in the fall, the refinery will start operating new treatment facilities "Biosfera": a modern biological complex will expand the composition of the plant's water treatment plants and will destroy almost all pollutants. After the launch of the "Biosphere", environmentalists will again come to the refinery, make a new sampling and analysis of wastewater - in order to compare them with the first sample. This will make it possible to verify the effectiveness of the new treatment complex and the environmental technologies used at the plant.

Construction of the complex treatment facilities"Biosphere" is one of the stages of modernization of the enterprise and an important part of the environmental protection program, which the owner of the plant, Gazprom Neft, has been implementing since 2011. The territory of the plant, where the Biosphere is now being built, was previously considered environmentally unfavorable. But for last years the situation has changed radically: according to Andrei Nagibin, chairman of the board of the all-Russian public organization Green Patrol, the Moscow Oil Refinery may well qualify for a Green Certificate.

This decision will be made after studying the information and monitoring the operation of the installation. But the openness of the enterprise and the demonstrated technologies have already been appreciated by us today, - Andrey Nagibin said. - The Moscow Oil Refinery has been under our close attention for several years. In the 90s, it was a real environmental threat to the city. Of particular concern was air pollution and groundwater pollution accumulated over 70 years on the territory of the enterprise, in the so-called "Black Sea", oil sludge. Today, on the site of this foul-smelling sludge reservoir, we see modern biological treatment facilities built. Already now there are no sharp unpleasant odors on the territory of the enterprise. There are no runoffs into the river, all open evaporation surfaces have been eliminated, water is purified with an efficiency of 95%, and after the launch of the Biosphere, there will be an almost closed cycle of water consumption.

Biosphere will use a unique technology for domestic oil refining for multi-stage wastewater treatment. First, wastewater will be driven through reliable mechanical treatment facilities that are already in operation. Then - through the "Biosphere": water will pass through the blocks of flotation, biological treatment, membrane and carbon filters, reverse osmosis unit.

Biosphere treatment facilities use special bacteria that can absorb and process oil residues, says Yuri Erokhin, head of the industrial safety and ecology department of the Moscow Oil Refinery. - In the final, purified water will pass through several hundred tons of activated carbon, as well as membranes, the pores of which are the size of a water molecule.

The plant's experts have calculated that after putting the "Biosphere" into operation, the enterprise will reduce water consumption by two and a half times. Almost 75% of the purified water will be reused in production - thus creating a practically closed cycle of its consumption.

Fundamental changes at the Moscow Refinery in the field of ecology began back in 2011 with the advent of a new owner, Gazprom Neft, - says Roman Pukalov, director of environmental programs at the Green Patrol organization. - Over the years, emissions of pollutants into the atmospheric air have been significantly reduced, a system of integrated control over their concentrations has been introduced, a huge buffer pond, the so-called "Black Sea", has been completely eliminated, and a complex of closed mechanical treatment facilities has been built. The company does not dump its wastewater into the Moscow River, but cleans it on its own and then directly transfers it to the city's wastewater treatment facilities. After the launch of the Biosphere, the load on the city's wastewater treatment facilities should be significantly reduced.

By the way, the launch of the Biosphere treatment facilities is included federal program events of the Year of Ecology in Russia.

Real, tangible benefits for the country's ecology are already being brought by practical measures, such as the launch of the Biosphere at the Moscow Oil Refinery, says Andrey Nagibin, chairman of the board of the all-Russian public organization Green Patrol. - It is gratifying to note that the process of environmental modernization has been going on at the Moscow Oil Refinery for several years, regardless of the Year of Ecology, and will continue in the future.

HELP "KP"

250 billion rubles have been invested in the modernization of the Moscow Oil Refinery of the Gazprom Neft companies. Since 2011, thanks to the reconstruction of wastewater treatment plants, the enterprise has reduced the impact of production on environment, and reduced emissions by 36%. It is planned that after the implementation of the next stage of environmental protection measures, by 2020 the impact of the plant on the environment will be reduced to almost zero.

Photo: Press Service of the Mayor and the Government of Moscow. Denis Grishkin

Thanks to the new Biosfera treatment facilities, the plant will be able to purify water from pollution by 99.9 percent, as well as reduce water intake from the Moskva River by two and a half times due to the reuse of treated water.

The Moscow Oil Refinery (MNPZ) in Kapotnya launched a new wastewater treatment plant "Biosfera". The project was implemented as part of a large-scale environmental program to modernize the enterprise.

“Since 2011, we have been implementing a large-scale program to improve the environment and quality of refinery products. Your products have helped reduce emissions by 20 percent from cars that take to the streets by the millions every day – by High Quality, environmental friendliness of the oil products that you produce,” he said during an inspection of the new treatment facilities.

Another important project of the enterprise concerns the discharge of water into the Moscow River. The Mayor of Moscow explained: “Today we are launching a plant that will provide complete water purification, so that the effluents will be generally cleaner than today in the Moscow River.”

The program of environmental modernization of the Moscow Oil Refinery has been in operation since 2011 and includes five major projects. These are improving the efficiency of wastewater treatment, reducing harmful emissions into the atmosphere, increasing the ecological class of automotive fuel and, accordingly, reducing the harmful effects of cars on the environment, reclaiming the plant’s territory, as well as creating an environmental control and monitoring system.

At the first stage of modernization, from 2011 to 2015, about 50 percent of environmental projects were implemented. This made it possible to reduce harmful effect plant on the environment about twice. At the second stage, from 2016 to 2020, it will be halved.

Arkady Yegizaryan, General Director of the enterprise, said that the refinery is to build a combined Euro+ oil refining unit, which will reduce gas emissions into the atmosphere by another 15 percent. “We have now completed the construction of the Biosphere, we are launching it. As Sergei Semenovich said, this is almost complete cleaning - by 99.9 percent - of our wastewater, the water will be very clean. We will return 75 percent of it to the circulation cycle, thereby reducing the fence from the Moscow River by two and a half to three times and, accordingly, the discharge into the Moscow River, ”he specified, adding that the river embankment near Kapotnya would be improved before July next year.

Pure water

Last year, the liquidation of obsolete open treatment facilities and oil sludge storage facilities was completed here. They were replaced by closed mechanical treatment facilities. A major overhaul of the water supply and sewerage systems was also carried out.

As a result, the enterprise completely eliminated the discharge of untreated wastewater and eliminated surface evaporation from treatment facilities. The level of purification was brought up to 95 percent, and the content of oil products in wastewater was reduced by six times.

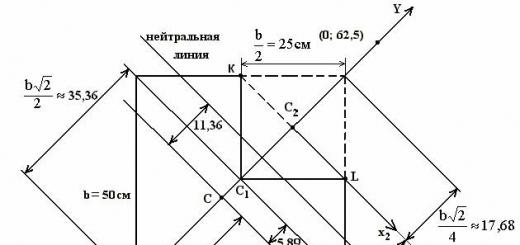

In the fall of this year, the plant completed The final stage creation of a wastewater treatment system. New biological treatment facilities "Biosfera" with a capacity of up to 1,400 cubic meters of water per hour were built at the plant. They consist of a two-stage flotation unit, a membrane biofilter, a reverse osmosis system (purification of impurities at molecular level), coal filters and centrifuges for dehydration of activated sludge and oil sludge.

Here, after passing through closed mechanical treatment facilities, wastewater from the Moscow Refinery enters. First, they are mixed to average the composition in tanks with a volume of 10 thousand cubic meters. Then, in the flotation unit, all mechanical impurities and oil products are knocked out from the effluents with a powerful air flow.

After that, the water passes into the central part of the "Biosphere" - a membrane biofilter. It is designed to remove suspended solids, organic compounds and biogenic elements (nitrogen and phosphorus). It is here that wastewater is mixed with sludge, which contains bacteria that can absorb and process oil residues. The sludge is filtered out of the water on membranes with pores thinner than a human hair.

At the end of the production chain, pressurized water is sequentially passed through carbon filters and reverse osmosis systems. At these stages, waste water passes through 200 tons of activated carbon and 1,440 special membranes, the size of which is not larger than a water molecule.

These treatment facilities guarantee almost complete, up to 99.9 percent, removal of all pollutants from factory effluents, which significantly exceeds regulatory requirements and corresponds to the best world indicators.

In addition, up to 75 percent of treated water will be returned to the production cycle. Accordingly, the water intake from the Moscow River will be reduced by two and a half times.

"Biosphere" is a unique ecological structure that has no analogues in our country. The project was developed in Russia on the basis of advanced technologies for domestic oil refining. More than 50 percent of the equipment is Russian-made.

According to experts, no more than 2,000 installations for the treatment of industrial effluents are currently operating on a membrane bioreactor worldwide, since this is the most expensive, but at the same time the most efficient technology. Investments in the project for the construction of treatment facilities at the plant amounted to more than nine billion rubles.

Fresh air

To reduce harmful emissions into the atmosphere, the Moscow Oil Refinery decommissioned a small bitumen plant. It was transferred to the technology of closed bottling, which made it possible to eliminate the unpleasant odor that arose during bitumen bottling.

Sulfur production units were reconstructed here, significantly reducing emissions of hydrogen sulfide and sulfur dioxide. All technological installations began to operate on environmentally friendly gas fuel.

From 2011 to 2015, the plant reduced air emissions by 36 percent.

Currently, the Moscow Oil Refinery is building a new Euro+ combined oil refining unit, which will replace the obsolete equipment of the small technological ring of the 1960s (five facilities). Its projected capacity is six million tons of oil per year. "Euro+" runs on environmentally friendly gas fuel, it is more compact, energy efficient, with a minimum of communications, joints and connections. Thanks to the installation, the plant will be able to reduce emissions from each ton of refined oil by up to 11 percent.

In addition, productivity will be doubled, energy efficiency will increase, and the area occupied by the installation will be reduced by 15 percent. The depth of oil refining will increase to 85 percent. The interval between scheduled repairs will increase from two to four years, which will ensure more stable operation of the enterprise.

Completion of the Euro+ construction is scheduled for 2018.

Pure land

By 2015, the plant eliminated production waste accumulated during the Soviet period (until 1991).

Pure gasoline

From 2011 to 2013, a catalytic cracking gasoline hydrotreating unit and a light naphtha isomerization unit were built at the plant. In addition, the diesel fuel hydrotreating unit was reconstructed.

In 2013, the Moscow Refinery switched to the production of motor fuel (gasoline and diesel fuel) of the Euro-5 environmental class. When using it, car engines emit five times less sulfur compounds compared to Euro-4.

Environmental control and monitoring

An integrated system for monitoring the state of air, water and the geological environment has been created on the territory of the enterprise and its environs. Also, eight chimneys are equipped with automated systems for local environmental monitoring of industrial emissions. And in residential areas adjacent to the Moscow Oil Refinery, air pollution is assessed at the automatic control stations Kapotnya and Golovachevo.

Capital Oil Refinery—80 years old

The Moscow Oil Refinery was commissioned in 1938. Next year, the capital's largest industrial enterprise will celebrate its 80th anniversary.

In the late 1970s and 1980s, a partial technical and environmental modernization was carried out here.

Now the plant annually processes more than 11 million tons of oil. The depth of processing is 72.3 percent. It produces 30 types of products and more than 60 grades of gasoline, diesel and jet fuel. Since 2013, manufactured products have been compliant with the Euro-5 environmental standard. The share of Moscow Oil Refinery in the eco-fuel market of the capital region is 38 percent.

The Moscow Oil Refinery is the largest supplier of bitumen for road construction in Russia and the largest taxpayer among industrial enterprises in the capital. The labor collective has about two thousand employees. The average salary is 103 thousand rubles.

Start-up and commissioning tests of the Biosfera innovative complex of biological treatment facilities have begun at the Gazprom Neft Moscow Oil Refinery. Moscow Mayor Sergei Sobyanin and Chairman of the Management Board of Gazprom Neft Alexander Dyukov visited the new production facility of the Moscow Refinery.

Construction of the "Biosphere" installation - environmental project a comprehensive program for the modernization of Gazprom Neft's oil refining assets, one of the key priorities of which is the gradual reduction of the production load on the environment. The construction of "Biosfera" by order of the Government of the Russian Federation is included in the federal action plan for the Year of Ecology in Russia. Investments by Gazprom Neft in the project amounted to 9 billion rubles.

Completion of the construction of Biosfera is an important stage of the program of environmental modernization of the plant and its final stage in terms of minimizing the impact on aquatic environment. A unique technological system developed by domestic engineers will complete the formation of the plant's water treatment complex and increase the efficiency of wastewater treatment to 99.9%. Through the use of modern technologies, Biosfera will ensure a closed water consumption cycle and significantly reduce the load on the city's wastewater treatment infrastructure. The Moscow Oil Refinery will reduce the intake of river water by 2.5 times, and 75% of treated effluents will be returned back to production.

“The Moscow Oil Refinery is implementing a large-scale environmental program, as a result of which the level of the enterprise's impact on the environment should decrease by about 4 times. Today the next stage of modernization has been completed. Wastewater treatment facilities "Biosfera" have been built, which will ensure the most complete purification of wastewater. In addition, the company will reduce water intake from the Moskva River by 2.5 times due to the reuse of treated water within a closed cycle. This is good news for all residents of the capital and the Moscow region. Especially for those who live near the plant and go for walks in parks located in the lower reaches of the Moskva River,” said Moscow Mayor Sergei Sobyanin.

Alexander Dyukov, Chairman of the Management Board of Gazprom Neft, noted: “The Moscow Refinery is by no means the only petrochemical enterprise operating within the boundaries of Moscow, but today it is the undisputed leader in terms of the scale of changes and the dynamics of production modernization. The projects that Gazprom Neft is implementing at the Moscow Refinery solve the company's priority tasks of minimizing the impact of production on the environment, improving the technological level and operating efficiency of the refinery. By investing in innovative environmental solutions, implementing modern digital production management technologies, we set new standards for industrial and environmental safety which will determine the further development of the entire Russian oil refining”.

Reference

"Biosfera" is a multi-stage wastewater treatment system, where industrial effluents enter after preliminary treatment at the operating mechanical treatment facilities of the Moscow Oil Refinery. At the first stage, water passes through the pressure flotation unit, where all the remaining mechanical impurities and oil products are knocked out with a powerful air flow. After the flotators, the water passes to the central part of the plant - the membrane bioreactor.

Here, wastewater is mixed with sludge, which contains microorganisms that can absorb and process oil residues. They are adapted to this environment and were grown especially for Biosfera at the Lyubertsy treatment facilities of Mosvodokanal. After the sludge has fulfilled its function, it is filtered through thousands of membranes, the pore diameter of which is smaller than a human hair. This is the most advanced water treatment solution in existence. In addition, the tank is completely waterproofed, all exhaust gases are specially treated at photoionization stations, which guarantee the complete removal of odors and pollutants. The air is first cleaned on filters, and then disinfected with ultraviolet light.

In the final stage, purified water is successively passed under pressure through 200 tons of activated carbon, and then through 1440 reverse osmosis membranes, the cell size of which is not larger than a water molecule. Only after that, purified water is returned to production, and filtered oil products are recycled. Part of the purified water is transferred through pipes directly to the city's wastewater treatment plant. The enterprise has no open drains to the Moscow River. Even rainwater is collected in the storm sewer system and treated.

Start-up and commissioning tests of the Biosfera innovative complex of biological treatment facilities have started at the Gazprom Neft Moscow Oil Refinery.

Moscow Mayor S. Sobyanin and Chairman of the Board of Gazprom Neft A. Dyukov visited the new production facility of the Moscow Refinery.

Completion of the construction of the "Biosphere" is the final stage of work to minimize the impact of the enterprise on the aquatic environment as part of the program of environmental modernization of the Moscow Oil Refinery.

Moscow Mayor S. Sobyanin stressed: “The Moscow Refinery is implementing a large-scale environmental program, as a result of which the level of the enterprise's impact on the environment should decrease by about 4 times. Today the next stage of modernization has been completed. Wastewater treatment facilities "Biosfera" have been built, which will ensure the most complete purification of wastewater. In addition, the company will reduce water intake from the Moskva River by 2.5 times due to the reuse of treated water within a closed cycle. This is good news for all residents of the capital and the Moscow region. Especially for those who live near the plant and go for walks in the parks located in the lower reaches of the Moskva River.”

Indeed, a unique technological system developed by domestic engineers will complete the formation of the plant's water treatment complex and increase the efficiency of wastewater treatment to 99.9%. Besides:

75% of the water used will be returned to the production cycle.

The consumption of fresh river water will decrease by 2.5 times and the load on the city's wastewater treatment facilities of Mosvodokanal will be reduced.

These are grandiose indicators that directly affect the growth of the environmental friendliness of the enterprise's water consumption.

A. Dyukov, Chairman of the Board of Gazprom Neft, noted: “The Moscow Refinery is by no means the only petrochemical enterprise operating within the boundaries of Moscow, but today it is the undisputed leader in terms of the scale of changes and the dynamics of production modernization. The projects that Gazprom Neft is implementing at the Moscow Refinery address the company's priority tasks of minimizing the impact of production on the environment, improving the technological level and operating efficiency of the refinery. By investing in innovative environmental solutions, introducing modern digital production management technologies, we are setting new standards for industrial and environmental safety, which will determine the further development of the entire Russian oil refining industry.”

Recall that the construction of Biosfera began in October 2015. This is an environmental project of a comprehensive program for the modernization of oil refining assets of Gazprom Neft.

The construction of the "Biosphere" by order of the Government of the Russian Federation is included in the federal action plan for the Year of Ecology in Russia.

Investments - more than 9 billion rubles.

According to the associate professor of the Department of Biotechnology of the Russian University of Chemical Technology named after D.I. Mendeleev, Ph.D. Kuznetsova A.E., despite the high cost compared to other options, the MBR treatment technology is promising primarily for the treatment of domestic and industrial wastewater, especially in urban areas, since it can significantly increase the productivity of treatment facilities, increase their compactness and reduce occupied areas.

He also noted that in the world, due to the emergence of a new generation of membranes and an increase in the cost of urban land, there is a rapid growth in treatment plants with MBR - annually by 10-30%.

The complex includes a 2-stage flotation unit, a carbon filter, a membrane bioreactor, as well as reverse osmosis and dehydration systems.

In March 2016, the installation of RVS-1000 steel tanks for preliminary wastewater treatment began.

In June 2016, the Moscow Refinery began installation of RVS-10000 tanks to collect industrial wastewater and balance it in composition before being fed into the treatment system.

In August 2016, the installation of a carbon filter unit began to remove organic compounds and oil products from industrial effluents.

In December 2016, the installation of the flotation system equipment was completed (according to the pressure flotation technology, in which contaminants are removed from the water using air flow). In total, 6 devices were installed with a total capacity of more than 5 thousand m3/hour.

Specialist of the Department of Industrial Water Treatment Projects "NPK Mediana-Filter" M. Zavyalova spoke about the uniqueness of the project: “BOS “Biosfera” is designed to treat the production effluent of the Moscow Oil Refinery, and is a whole complex of new generation facilities. All effluents sequentially pass through flotation units, biological treatment units, membrane and carbon filters, and a reverse osmosis unit. All equipment is designed to maintain a stable mode of operation in different operating modes.

The membrane bioreactor planned in this unit will provide efficient biological wastewater treatment, and the unit for deep post-treatment of wastewater based on reverse osmosis units will provide highly purified water for reuse by the enterprise. After the launch of the complex, the volume of waste water will be significantly reduced and, as now, it will flow directly to the treatment facilities of Mosvodokanal. BOS “Biosfera” are unique treatment facilities and have no analogues in Russia.”

Throughout the entire period of construction of the complex at the Moscow Oil Refinery, indicators of water use efficiency have been steadily increasing. Now Biosfera will start operating at full capacity, and further modernization of the Moscow Oil Refinery will continue as planned until 2020.

Ahead of the launch of the most modern combined oil refining unit Euro+

- Vertical version from 0.6 - 2 m 3 / day. (energy saving, does not work all the time)

- Horizontal version from 0.6 - 300 m 3 / day. (works all the time)

The system is volatile, it works constantly, in case of a power outage it works offline for up to a week, the degree of purification drops. The minimum service life is 50 years. It is made of high-strength polypropylene, the Czech production. High degree purification of HBSW up to 98% of technical effluents.

The biological treatment station "BIOSPHERA" needs maintenance no more than once a year - the rest of the time it is completely autonomous in operation. VOC is equipped with a system of protection against large debris.

Were held laboratory research for wastewater treatment VOC "BIOSPHERE" Results of the study:

| NAME | before cleaning | after cleaning |

| Suspended solids (mg/l) | 168.9±1.1 | 2.5±0.1 |

| Oil products (mg/l) | 2,9 | 0,03 |

| Ammonium nitrogen (mg/l) | 6,1 | 0,3 |

| BOD5 (mg/l) | 22,3 | 1,6 |

| surfactant (mg/l) | 22,8 | 0,16 |

| Nitrites (mg/l) | 0,4 | less than 0.005 |

| Nitrates (mg/l) | 18.1 | 1,2 |

| Phosphates (mg/l) | 2,8 | 0,1 |

- The cleaning efficiency for suspended solids was -98.5%

- The cleaning efficiency for oil products was -98.96%

- The purification efficiency for ammonium nitrogen was 95%

- BOD Cleaning Efficiency5 was -92.8%

- The cleaning efficiency for surfactants was -94.28%

- The nitrite cleaning efficiency was at least 98.75%

- Phosphate cleaning efficiency was -96.4%

These studies of wastewater treatment are confirmed by certificates.

in horizontal version:

LOS "BIOSPHERE" of horizontal design 0.6 - 60 m 3 / day, from 3 - 300 people of permanent residence.

Water disposal methods: gravity / forced

The stations are equipped with diaphragm compressors "HIBLOW" by the Japanese manufacturer Techno Takatsuki or "SECOH" by the Japanese manufacturer Secoh Sangyo Co Ltd. Inside the system, in a separate sealed compartment, there is a control unit in which the compressor is installed.

The operation of the installation includes the sequential passage of waste water through the sections of mechanical and biological treatment. Effluent first enters the receiving chamber for mechanical treatment, where sand and other insoluble impurities are deposited. Next, the wastewater enters the biological treatment, due to the ability of microorganisms to use some pollutants as a source of nutrition. Biological treatment is carried out in two stages: in the absence of oxygen (anaerobic) and in the presence of dissolved oxygen (aerobic).

Autonomous sewerage, septic tank, LOS "BIOSPHERE" of horizontal design

Particularly important in anaerobic treatment is the removal of nitrogen from the water, which has an extremely negative effect on the fauna of reservoirs. When the effluents pass through an anaerobic bioreactor with a ruff bioload, due to enzymes produced by microorganisms, the formation of an ammonium ion from organic compounds occurs. Nitrogen is used for the growth of microorganisms, and thus part of the inorganic nitrogen passes into the newly formed bacterial cells. Then, wastewater containing ammonium nitrogen enters the aerotank, where the ammonium ion is nitrified by activated sludge microorganisms into nitrite and nitrate forms:

NH4++2O-2 =NO2- +2H2O

2 NO2-+ O-2 = 2 NO3-

In the secondary clarifier, nitrifying activated sludge is deposited, it is recirculated to a septic tank - a sludge mineralization chamber, and the remaining organic compounds are oxidized by nitrates. In this case, free nitrogen is released, which is discharged through the duct.

Further purification is carried out in a brush-loaded biotank, the bottom part of which is equipped with an aerator. Due to the access of oxygen to the load, aerobic microorganisms develop, which are necessary for the absorption and oxidation of contaminants. The next step is to calm the sludge mixture and settling it on the bottom of the tertiary clarifier. The purified wastewater is separated from the activated sludge, which, as it accumulates, is removed from the sump.

Purified water is diverted to the nearest watercourse. If necessary, wastewater can be discharged into a reservoir (a well made of metal or reinforced concrete rings). When discharging treated effluents for fisheries, an additional UV lamp is installed.

Let's consider in more detail the work of Los "BIOSPHERE"

in vertical version:

A submersible Karcher pump (manufacturer Germany) is installed in the vertical execution system. Drainage methods: gravity / forced

Autonomous sewerage, septic tank, VOC "BIOSPHERE" vertical design

Principle of operation:

Wastewater treatment in the BIOSPHERE sewer system takes place in two stages:

1. The first stage consists in the settling of suspended particles in a three-chamber settling tank. The sump consists of 3 separate sections with overflows through which sewage flows flow. The overflows are located in such a way that the wastewater flows at the lowest speed, due to which coarse suspended particles settle to the bottom in each chamber. The first capacity is single-chamber and maximum volume, the second and third are the same. So, for example, the volume of the chambers of the BIOSPHERE 5 installation is 800 l, 400 l and 400 l, and, accordingly, the total volume of the sump is 1.6 m3.

2. The second stage of post-treatment in the bioreactor - from the third chamber, clarified wastewater is pumped into the upper part installations and through the sprayer are evenly sprayed over the entire area of the brush load. Also, at the time of spraying, wastewater is saturated with oxygen. A bioreactor is a structure in which waste water is filtered through a feed material covered with a biological film (biofilm) formed by colonies of microorganisms. Further, part of the water saturated with bioorganisms returns to the first chamber, which makes it possible to accelerate the process of decomposition and sedimentation of suspended particles. The main volume of purified water is returned to the third chamber. The selection for the outlet of purified water from the installation comes from the middle part of the third chamber. This process prevents the sludge from the bottom and dead bacterial colonies floating on the surface from leaving the unit.

The processes of sorption and destruction of sewage contaminants in biological filters are in many respects similar to the processes in soil treatment facilities in irrigation fields and filtration fields. However, the processes of biological oxidation of organic pollutants in biofilters proceed much more intensively due to the increased porosity of the feed material compared to the porosity of soils. So, for example, the porosity of brush loading is ten times higher than the porosity of sand, one of the best natural materials for irrigation fields.

Being filtered through the loading of the biofilter, contaminated water leaves insoluble impurities in it that have not settled in the primary and secondary clarifiers, as well as colloidal and dissolved organic substances sorbed by the biological film. The term "filtration" should not be simplified to understand only the processes of mechanical filtering through the thickness of the feed material. A biofilter is a biological treatment facility with a fixed biomass fixed on the surface of a carrier medium (feed material), which carries out the processes of extraction and complex biological processing of contaminants from wastewater. Biofilm microorganisms in the process of enzymatic reactions oxidize organic substances, while receiving nutrition and energy necessary for their life. Part organic matter microorganisms use as a material to increase their mass. Thus, in the process of metabolic reactions, contaminants are converted into simple compounds (water, mineral compounds and gases), as a result, organic contaminants are removed from the wastewater, denitrification processes take place and the mass of the active biological film in the body of the biofilter increases. The spent and dead film is washed off and removed from the body of the biofilter by the flowing sewage. The oxygen necessary for the biochemical process enters the bulk of the load through the natural ventilation of the filter.

Attention!!! The manufacturer reserves the right to make changes to various design parameters without compromising performance.