Smolensk NPP is the city-forming, leading enterprise of the region, the largest in the fuel and energy balance of the region. Annually, the station produces an average of 20 billion kWh of electricity, which is more than 80% of the total amount generated by the energy enterprises of the Smolensk region.

Smolensk NPP operates three power units with RBMK-1000. The first stage belongs to the second generation of nuclear power plants with RBMK-1000 reactors, the second stage - to the third.

Smolensk NPP was repeatedly recognized as the winner of the industry competition "The Best NPP of Russia" (in 1992 and 1993), in 1999 it entered the top three.

In 2000, the nuclear power plant took first place in the competition "Russian Organization of High Social Efficiency"; in 2006 it was awarded the title of "Best NPP in Russia" in an industry competition in the field of safety culture;

in 2007 - the first among Russian nuclear power plants to receive international certificate compliance of the quality management system with the ISO 9001:2000 standard and was recognized as the best NPP in Russia in terms of ensuring social safety and work with personnel.

In 2009, SNPP received a certificate of compliance of the environmental management system with the requirements of the national standard GOST R ISO 14001-2007 and was recognized as the best NPP in Russia in the field of "Physical Protection".

In 2011, Smolensk NPP became the winner in the competition "Best NPP in Russia" based on the results of 2010 and was recognized as the best NPP in terms of safety culture. As part of the implementation of the program to extend the service life of the Smolensk NPP, a major overhaul and modernization of power unit No. 1 was carried out.

In 2011, Smolensk NPP: confirmed the compliance of the occupational safety and health management system with the international standard OHSAS 18001:2007, as well as the compliance of the environmental management system with the national standard GOST R ISO 14001-2007; recognized as the Concern's best plant in the field of safety culture; received a "Certificate of Trust in the Employer" based on the results of an audit by the State Labor Inspectorate for the Smolensk Region.

The nuclear power plant is located in the Smolensk region, the distance to the satellite city (the city of Desnogorsk) is 3 km; to the regional center (city of Smolensk) - 150 km.

Installed electric power — 3000 MW.

Smolensk NPP, news:

Photo of Smolensk NPP:

News

23 April 2019

A judo tournament was held with the support of Smolensk NPP

On April 20, the 24th youth judo wrestling tournament was held, dedicated to the memory of Nikolai Savinich, the founder of the Desnogorsk sports school.

22 April 2019

Smolensk NPP: nuclear scientists for safe work

Smolensk NPP not only creates all the conditions for the safe performance of production tasks, but also carries out extensive information and explanatory work on compliance with labor protection rules and injury prevention.

News 1 - 2 of 534

Home | Previous | 1 | Track. | End | All

SMOLENSK NPP

Location: near the city of Desnogorsk (Smolensk region)

Reactor type: RBMK-1000

Number of power units: 3

Smolensk NPP is the city-forming leading enterprise of the region, the largest in the fuel and energy balance of the region. Annually, the station produces an average of 20 billion kWh of electricity, which is more than 75% of the total amount of electricity generated by the energy enterprises of the Smolensk region. The SPP operates three power units with RBMK-1000 reactors. The first stage belongs to the second generation of nuclear power plants with RBMK-1000 reactors, the second - to the third.

AT 2000 Smolensk NPP took 1st place in the All-Russian competition "Russian Organization of High Social Efficiency".In 2007 nuclear power plant the first among Russian NPPs, was awarded a certificate of compliance of the quality management system with the international standard ISO 9001. In 2009received a certificate of conformity of the environmental management system of the plant with the requirements of the international standard ISO 14001. In the same year, the Smolensk NPP was recognized as the best plant in Russia in the direction of "Physical Protection".

AT 2010 As a result of safe and reliable operation of power units, modernization and introduction of advanced production technologies, preparedness and professionalism of the personnel, Smolensk NPP was recognized as a leader in the corporate competitions "Best NPP in Russia by the end of the year" and "Best NPP in Russia in terms of safety culture".

AT 2011

Smolensk NPP became the winner in the competition "The Best NPP of Russia" based on the results of 2010 and was recognized as the best NPP in terms of safety culture. As part of the implementation of the program to extend the life of the Smolensk NPP, a major overhaul and modernization of power unit No. 1 was carried out.the Certificate of acceptance into operation of the 1st launch complex of KP RAO was signed. In addition, Mr.A group of highly qualified experts in the field of nuclear safety of the International Atomic Energy Agency (IAEA) conducted an OSART mission at the Smolensk NPP to verify the compliance of the plant's safe operation with international standards. Based on the results of the audit, a positive assessment was given and a number of positive practices recommended for implementation at nuclear power plants of the world were noted: high operational reliability of power units, professional training of personnel, and others.

AT 2013 SNPP became the owner of the international environmental certificate and the golden sign "International Ecologists Initiative 100% eco quality", confirming the environmental friendliness of the enterprise. In the same month, Smolensk NPP was awarded the main prize of international ecologists "Global Eco Brand" in the nomination "Leader of Socially and Environmentally Responsible Business".

AT 2016 Smolensk NPP was included in the number of exemplary RPS enterprises in the industry and received the status of "Enterprise - RPS Leader". As well asfor reliability and safety, was recognized as the leader in the corporate competition "The Best NPP in Russia in terms of safety culture"; Smolensk NPP "Best NPP in Russia" according to the results of the 2015 traditional industry competition. In the same year bAn important decision was made - Rostekhnadzor issued licenses, and at the government level a corresponding order was issued to locate two VVER-TOI power units in the Smolensk region, replacing the capacities of existing units that are to be decommissioned.

In 2017, Smolensk NPP was recognized as an environmentally exemplary organization by Rosenergoatom Concern JSC, becoming the winner of the All-Russian competition "Health and Safety", held with the support of the Ministry of Labor and Social Protection of the Russian Federation in two categories at once: "Development and implementation of highly efficient labor protection management systems ” and “Development of measuring instruments, methods, techniques and technologies for assessing working conditions”.

The distance to the satellite city (Desnogorsk) is 3 km, to the regional center (Smolensk) - 150 km.

OPERATING POWER UNITS OF SMOLENSK NPP

| POWER UNIT NUMBER | TYPE OF REACTOR | INSTALLED CAPACITY, M W | LAUNCH DATE |

|---|---|---|---|

| 1 | RBMK-1000 | 1000 | 09.12.1982 |

| 2 | RBMK-1000 | 1000 | 31.05.1985 |

| 3 | RBMK-1000 | 1000 | 17.01.1990 |

| Total installed capacity 3000 MW |

Last week I took a trip to a place I never dreamed of before. For those who often write about large industrial facilities, getting to an operating nuclear power plant is already a holiday. For me, this is a double celebration! For the first time I visited a large and strategically important facility.

Smolensk NPP is located in Desnogorsk. This city is located approximately in the middle between Smolensk and Bryansk, not far from Roslavl.

1. First, some basic information.

2. There are 10 nuclear power plants in Russia. In total, they generate 16% of the electricity in the country.

3. Smolensk NPP was put into operation in 1982. In the future, Solenskaya NPP-2 will be built to gradually decommission the capacities of NPP-1.

4. In order not to rewrite the pictures, I immediately designate the scheme of operation of the SAES.

5. And now we are moving to the territory of the nuclear power plant.

6. The cooling pond is teeming with fish. Its quantity is huge because of the temperature. It's consistently warmer here. Specialists from Moscow specially come to control the amount of fish!

6. Also, algae actively live and multiply here.

7. At the entrance we are met by a large mosaic with Vladimir Ilyich.

8. Is it worth talking about safety at nuclear power plants? Every person in their right mind wants to live. Numerous posters in workplaces, corridors and intermediate rooms are bright, clear and sometimes very motivating.

9. Passage to the territory for the guest only with equipment that is declared in advance. Dressing completely in white clothes. In general, I was pleasantly surprised that it was possible to shoot a lot. In any case, everything cannot be shown, but in my little experience there were already places where there were much more prohibitions.

10. Unfortunately, my stupidity sometimes goes beyond. I managed to forget to remove the polarizing filter for screen shots. So they came out darker than the real one.

11. The NPP control system is a huge shield with a bunch of buttons and levers.

12. To shoot it completely you need to use a 360 camera or ask everyone to step out of the frame and shoot from the very corner.

13. Workplace.

14. If you don't know what it is, you don't represent a nuclear power plant device. These buttons are responsible for controlling the rods - the basis of the reactor.

15. And three red levers nearby - shutdown of all three reactors. I hope that they will not need to be used in extreme circumstances or for prevention.

16.

17. Red lines on the floor - a place where it is dangerous to go. Just in case.

18. Ahead is the most important, most interesting and most desired place by all guests of the nuclear power plant.

19. The central hall, in which the base of the entire station is located - the power unit. We are in one of three such.

20. Before us is the reactor itself. Its upper part is called the plateau. The people (I used to love games about Chernobyl) often called the lid, the surface. Internally, the device resembles a large bunch of pencils. Remember in your school years there were heaps of unsharpened pencils tightened with an elastic band? Here is something similar

21. Under the cells are fuel assemblies in the form of tubes with uranium pellets.

22. To be honest, it was scary to enter the plateau for the first time. It would seem that I can imagine what is under me, others have already gone, but I'm scared. Then he decided anyway. Fine. Feelings are special. I even made a rare photo for myself "at the feet".

23. The height of the room is designed for a calm rise of each part of the structure. And the yellow "pipe" in the middle of the photo will soon generate electricity.

24. As you can see, the design consists of ordinary tubes, inside which are uranium tablets. Now, until they are lowered into the reactor, they do not pose a danger.

25. In order to carry out work on the replacement of parts in the hall there is a special machine.

26. This is a crane that moves throughout the area and drags structural elements. Can be controlled both automatically and manually.

27. Workplace.

28. Waste material remains here for 1.5 years.

29. General form the design is impressive. While I was in this hall, I was reached with an interview. They pulled the first sensations out of me. Then it really seemed to me that everything is compact here. yes, I understand that large object high power with huge weight and large scale. But for some reason, my distorted idea initially expected that everything here would be not just big, but huge.

30. And of course everything is under control.

32.

33. And this is the turbine hall. The place where electricity appears.

34. This layered design generates electrical energy from steam by moving the blades in a turbine at a speed of 3,000 revolutions per minute.

35. All characteristics.

36. The rumble standing here is a little misleading.

37. It may surprise you, but it's not here a large number of people. Those who are - in soundproof rooms. Automation works flawlessly and protects the system in case of emergency.

38.

39. To study everything that is in this picture, I, a humanist, will need to spend a year.

40.

41.

42.

43. Part of the nuclear power plant capacity goes to serve the city.

44. And in the end, let's look briefly into the laboratory of external radiation monitoring. It is no longer at the nuclear power plant, but in the city.

45. So that you understand the level of radiation in the vicinity of the station, I post the table in full. For comparison, in St. Petersburg on the embankments, the indicator from the second column is 0.45, and in Moscow in places 0.60.

46. Numerous tests are still being carried out here of everything that is possible.

47. But I think that it is wrong to rewrite Wikipedia, and it is she who will tell you better about the meaning and purpose of devices.

My gratitude to the organizers of the blog tour, the NPP staff and the security service! I didn't expect to be able to photograph everything that seems interesting!

Thank you for your attention! Stay in touch!

Smolensk NPP is a nuclear power plant, located 3 km from the city of Desnogorsk, Smolensk region, and the largest energy enterprise in the northwestern region of the country's unified energy system with a capacity of 3000 MW. In the period from 1982 to 1990, three power units with RMBC-1000 reactors of an improved design with a number of advanced systems that ensure the safe operation of the NPP came into operation at the Smolensk NPP.

Smolensk NPP operates three power units with RBMK-1000 reactors. The project provided for the construction of two phases, two units with common auxiliary facilities and systems in each, but due to the termination in 1986 (due to the Chernobyl accident) of the construction of the fourth power unit, the second phase remained unfinished.

Ilya Varlamov writes: We arrived in Desnogorsk by bus early in the morning. Part of the group went to photograph the city, the other to fill up on sofas. Immediately after a short press conference, we went to the nuclear power plant. With photography, everything is very strict. Filming is allowed only from certain points under the supervision of the security personnel of the power plant.

Desnogorsk. What does this name tell you? For the average citizen, the word sounds as bright as Opochka, Vykhino or Bologoe - another locality in the vast expanses of our vast country. Residents of the Smolensk region know (the situation obliges) that Smolenskaya is located near the city nuclear power plant. But as soon as you pronounce the word "Desnogorsk" in the company of fishermen, you will hear a chorus of approval, emotional exclamations and cries of joy. For a fisherman, Desnogorsk, as for a climber, Everest, is the place where he flies in his dreams. Still would. Near the city there is a pond with an area of 44 square kilometers, where the water never freezes - this is the SNPP reservoir. The station gives heat to the reservoir all year round. The pond abounds with fish. Bream, crucian carp, pike, white and mottled silver carps, black and white carp, carp, catfish, African telapia and even freshwater shrimp - this is not a complete list of the inhabitants of the SNPP reservoir.

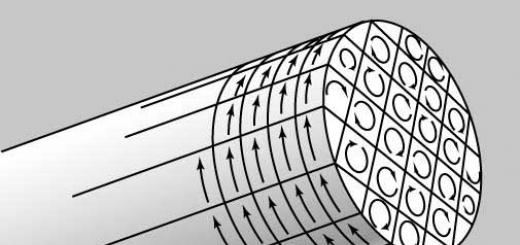

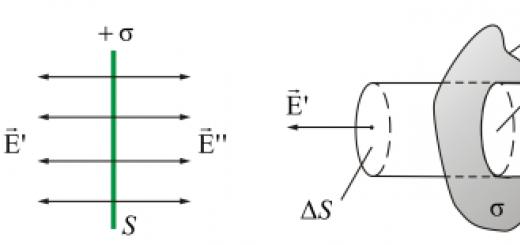

Power units with RBMK-1000 single-loop reactors. This means that the steam for the turbines is generated directly from the water that cools the reactor. Each power unit includes: one reactor with a capacity of 3200 MW (t) and two turbogenerators with a capacity of 500 MW (e) each. Turbine generators are installed in the turbine hall, common for all three units, with a length of about 600 m, each reactor is located in a separate building. The station operates only in the basic mode, its load does not depend on changes in the needs of the power system.

There are 10 nuclear power plants operating in Russia today. They bring light, warmth and joy to homes. Do you think that each nuclear power plant takes on 1/10 of this positive work? You are wrong. Each station is strong in its own way, for example, the Smolensk NPP generates 1/7 of all "nuclear electricity" in Russia, annually delivering an average of 20 billion kWh of electricity to the country's energy system.

You know that science fiction writers only come in second on the "People with the Worst Fantasy" list. Who comes first? Specialists who design safety systems for nuclear power plants. They are required not only to come up with a situation that simply cannot be, but also to develop protection against it. During the construction of the SPP, the fantasy of these specialists played out in earnest.

All power units of the station are equipped with accident localization systems that exclude the release of radioactive substances in environment even in the most severe accidents associated with a complete rupture of the pipelines of the reactor cooling circuit. All equipment of the cooling circuit is placed in sealed reinforced concrete boxes that can withstand pressure up to 4.5 kgf per square centimeter. Is it a lot or a little? Judge for yourself. Overpressure generated by the shock wave atomic explosion in the zone of complete destruction (the zone closest to the epicenter of the explosion atomic bomb) is almost 10 times less (0.5 kgf/cm).

Do you know that a circle with a radius of 30 kilometers has been built around the SPP with an invisible compass? Everything inside it is called the Observation Zone. In this zone you will not meet people in civilian clothes, there are no humanoid robots and superspecial forces there. It is called the observation zone because it closely analyzes the air, water and soil for changes radiation background. Automatic sensors show that the background corresponds to natural values.

In addition, in the observation zone, 11 springs, which are known as holy springs, have been restored and landscaped by the SNP employees.

Getting to the station is not easy. At the beginning, the employee applies a magnetic pass to a special reader. Then he enters the compartment where he must enter the password and take palm prints, weighing is also carried out (permissible discrepancy is not more than 10 kg) and photo verification. Only after all these procedures, the employee goes to the locker room or for a medical examination.

Everyone is given special socks, boots, bathrobes, hats, gloves, ear plugs and helmets.

At the exit, the employee passes 2 levels of radiation control.

A special radiation sensor is hung on the chest.

Engine room. Turbines K-500 65-3000 with TVV-500 generators with a capacity of 500 MW are installed at the power units of the Smolensk NPP. All rotors of the turbine and generator cylinders are combined into one shaft. Shaft speed - 3000 min -1. The total length of the turbogenerator is 39m, its mass is 1200t, the total mass of the rotors is about 200t.

The main circulation pumps are designed to create coolant circulation in the NPP primary circuit. Control over the operation of the MCP is carried out remotely from the block control panel of the NPP. The pump housing is welded to the main circulation circuit of the reactor plant. The body has 3 pins for connecting locks with vertical and horizontal release devices, which serve to absorb seismic loads.

Central reactor hall. The reactor is placed in a reinforced concrete shaft with dimensions of 21.6x21.6x25.5 m. The mass of the reactor is transferred to the concrete through metal structures, which simultaneously serve as protection against radiation and, together with the reactor casing, form a sealed cavity - the reactor space. Inside the reactor space there is a cylindrical graphite stack with a diameter of 14 and a height of 8 m, consisting of blocks assembled into columns with dimensions of 250x250x500 mm with vertical holes for installing channels in the center. To prevent oxidation of graphite and improve the transfer of heat from graphite to coolant, the reactor space is filled with a nitrogen-helium mixture.

RBMK reactors use uranium dioxide U235 as fuel. Natural uranium contains 0.8% of the U235 isotope. To reduce the size of the reactor, the content of U235 in the fuel is preliminary to 2 or 2.4% at enrichment plants.

The fuel element (TVEL) is a zirconium tube with a height of 3.5 m and a wall thickness of 0.9 mm with 88 mm enclosed in it, a wall thickness of 4 mm, and the reactor is controlled by rods uniformly distributed over the reactor 211 containing neutron absorbing from below, washes from the fuel elements. The fuel cassette is installed in the technological channel. The number of technological channels in the reactor is 1661.

Vertical green tubes (18 rods with a diameter of 15 mm) are fuel pellets.

Water is supplied to the channels from below, washes from the fuel elements and heats up, and part of it turns into steam. The resulting steam-water mixture is discharged from the upper part of the channel. To regulate the flow and heats up, and part of its technological channels intended for the installation of fuel at the same time turns into steam. The resulting steam-water mixture is discharged from the upper part of the channel. To control the flow of water at the inlet to each channel, shut-off and control valves are provided.

The advantage of RBMK over vessel-type reactors, the replacement of spent fuel cartridges, in which the reactor needs to be shut down, is the possibility of reloading the cartridges when the reactor is operating at rated power.

Reloading is carried out by an unloading and loading machine (RZM), which is controlled remotely. The machine is sealed to top technological channel, the pressure in it is equalized with the pressure in the channel, then the spent fuel cartridge is removed and a fresh one is installed in its place. RZM design provides reliable biological protection from radiation, during overload, the radiation situation in the central hall almost does not change.

When the reactor is operated at rated power, one or two fresh fuel cartridges are loaded per day. Spent fuel is first placed in special spent fuel pools located in the central hall, and then, as they fill up, it will be transported to a separate spent nuclear fuel storage facility. The closed loop for removing heat from the reactor is called the multiple forced circulation loop (MPC). It consists of two independent loops, each of which cools half of the reactor.

At a depth of 2 meters, a blue glow is visible. This is the Vavilov-Cherenkov effect - a glow caused in a transparent medium by a charged particle that moves at a speed exceeding the phase velocity of light in this medium. Cherenkov radiation is widely used in high-energy physics to detect relativistic particles and determine their velocities.

Block control panel. Here I listened to everything, so only pictures.

Management and IT consulting services. An information management system based on the TRIM-Technical Management solution has been implemented.

Solution structure:

TRIM-M/W/P/B/DOC/D/C/A/SP

Project description:

Implementation information system support for the management of the operation of the Desna-2 nuclear power plant.

Stage 1

Subdivisions covered by the system - NPP management, workshops - reactor, turbine, chemical, electrical, centralized repair, adjustment and testing of equipment, departments - operation of buildings and structures, radiation safety, metal and welding control, preparation and repairs. Service organizations are connected to work in the system, including JSC Atomenergoremont, JSC Smolenskenergoremont. The number of users is 540.

Stage 2

Expansion of the functionality of the system in terms of maintenance and repair management, warehouse management. Integration with the CE-2 accounting system and the BOSS-Kadrovik personnel management system. The customer has purchased additional TRIM licenses. Increasing the number of jobs in departments. The number of users is 900.

Stage 3

Implementation of a logistics subsystem (MTS). The customer has purchased additional TRIM licenses. Increasing the number of jobs, connecting the departments that are part of the management of production and technical equipment - departments of supply, supply, contracts, warehouses, AHO and others. The number of users is 1550.

Beginning of work:

Stage 1 - October 2002

Stage 2 - May 2005

Stage 3 - December 2007

Project status:

Stage 1 - the system was put into commercial operation in April 2005.

Stage 2 - work completed in December 2007

Stage 3 - the MTS system was put into operation in December 2009.

Customer feedback

Chief Engineer of Smolensk NPP

"With the commissioning of the system, the system has become vital for the station, since it has taken on some of the functions directly related to assessing the technical condition of the equipment and maintaining it at the required level. In addition, there is a real opportunity to account for all the work performed at the station, for an objective taking into account and planning the needs of all types of resources in the operation of the plant. In today's conditions, this is no less important than ensuring the safety of nuclear power plants."