What is acetone? The formula for this ketone is seen in school course chemistry. But not everyone has an idea of how dangerous the smell of this compound is and what properties this organic substance has.

Features of acetone

Technical acetone is the most common solvent used in modern construction. Since this compound has a low level of toxicity, it is also used in the pharmaceutical and food industries.

Technical acetone is used as a chemical raw material in the production of numerous organic compounds.

Doctors consider it a narcotic substance. When inhaling concentrated acetone vapors, serious poisoning and damage to the central nervous system are possible. This compound poses a serious threat to the younger generation. Drug users who use acetone vapor to induce a state of euphoria are at great risk. Doctors fear not only for the physical health of children, but also for their mental state.

A dose of 60 ml is considered lethal. When a significant amount of ketone enters the body, loss of consciousness occurs, and after 8-12 hours - death.

Physical Properties

Under normal conditions, this compound is in a liquid state, has no color, and has a specific odor. Acetone, the formula of which is CH3CHNOCH3, has hygroscopic properties. This compound is miscible in unlimited quantities with water, ethyl alcohol, methanol, chloroform. It has a low melting point.

Features of use

Currently, the scope of acetone is quite wide. It is rightfully considered one of the most popular products used in the creation and production of paints and varnishes, in finishing works, in the chemical industry, and in construction. Increasingly, acetone is used to degrease fur and wool, to remove wax from lubricating oils. It is this organic substance that painters and plasterers use in their professional activities.

How to save acetone, whose formula is CH3COCH3? In order to protect this volatile substance from negative impact ultraviolet rays, it is placed in plastic, glass, metal bottles away from UV.

The room where a significant amount of acetone is supposed to be placed must be systematically ventilated and high-quality ventilation installed.

Features of chemical properties

This compound got its name from the Latin word "acetum", meaning "vinegar" in translation. The fact is that chemical formula acetone C3H6O appeared much later than the substance itself was synthesized. It was obtained from acetates and then used to make glacial synthetic acetic acid.

Andreas Libavius is considered the discoverer of the compound. At the end of the 16th century, by dry distillation of lead acetate, he managed to obtain a substance chemical composition which was deciphered only in the 30s of the XIX century.

Acetone, whose formula is CH3COCH3, was obtained by coking wood until the beginning of the 20th century. After the increase in demand during the First World War, it organic compound, new methods of synthesis began to appear.

Acetone (GOST 2768-84) is a technical liquid. In terms of chemical activity, this compound is one of the most reactive in the class of ketones. Under the influence of alkalis, adol condensation is observed, as a result of which diacetone alcohol is formed.

During pyrolysis, ketene is obtained from it. In reaction with hydrogen cyanide, acetone cyanidanhydrin is formed. Propanone is characterized by the substitution of hydrogen atoms for halogens, which occurs at elevated temperatures (or in the presence of a catalyst).

How to get

At present, the majority of the oxygen-containing compound is obtained from propene. Technical acetone (GOST 2768-84) must have certain physical and operational characteristics.

The cumene method consists of three stages and involves the production of acetone from benzene. First, cumene is obtained by alkylating it with propene, then the resulting product is oxidized to hydroperoxide and split under the influence of sulfuric acid to acetone and phenol.

In addition, this carbonyl compound is obtained by the catalytic oxidation of isopropanol at a temperature of about 600 degrees Celsius. The accelerators of the process are metallic silver, copper, platinum, nickel.

Among the classical technologies for the production of acetone, the direct oxidation of propene is of particular interest. This process is carried out at elevated pressure and the presence of bivalent palladium chloride as a catalyst.

You can also get acetone by fermenting starch under the influence of the bacteria Clostridium acetobutylicum. In addition to the ketone, butanol will be present among the reaction products. Among the disadvantages of this option for obtaining acetone, we note an insignificant percentage yield.

Conclusion

Propanone is a typical representative of carbonyl compounds. Consumers are familiar with it as a solvent and degreaser. It is indispensable in the manufacture of varnishes, medicines, explosives. It is acetone that is part of the glue for film, is a means for cleaning surfaces from mounting foam and superglue, a means for washing injection engines and a way to increase the octane number of fuel, etc.

The table shows the thermophysical properties of benzene vapor C 6 H 6 at atmospheric pressure.

The values of the following properties are given: density, heat capacity, thermal conductivity coefficient, dynamic and kinematic viscosity, thermal diffusivity, Prandtl number depending on temperature. Properties are given in the temperature range from .

According to the table, it can be seen that the values of the density and Prandtl number decrease with increasing temperature of gaseous benzene. The specific heat capacity, thermal conductivity, viscosity and thermal diffusivity increase their values when benzene vapor is heated.

It should be noted that the vapor density of benzene at a temperature of 300 K (27 ° C) is 3.04 kg / m 3, which is much lower than that of liquid benzene (see).

Note: Be careful! The thermal conductivity in the table is given to the power of 10 3 Do not forget to divide by 1000.

Thermal conductivity of benzene vapor

The table gives the values of the thermal conductivity of benzene vapor at atmospheric pressure depending on the temperature in the range from 325 to 450 K.

Note: Be careful! The thermal conductivity in the table is given to the power of 10 4 . Don't forget to divide by 10000.

The table shows the pressure values saturated steam benzene in the temperature range from 280 to 560 K. Obviously, when benzene is heated, its saturated vapor pressure increases.

Sources:

1.

2.

3. Volkov A. I., Zharsky I. M. Big chemical reference book. - M: Soviet School, 2005. - 608 p.

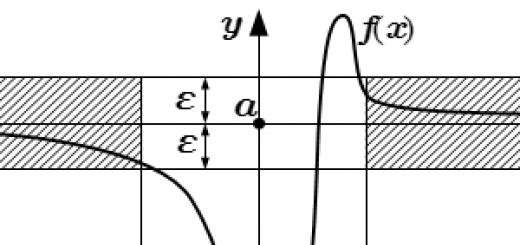

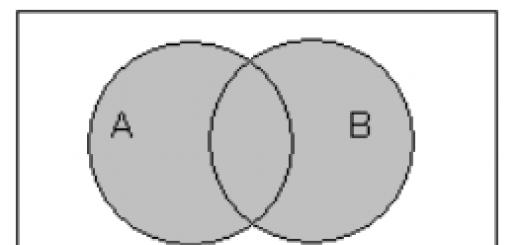

The saturated vapor pressure of a liquid increases with increasing temperature (Fig. 8.2), and as soon as it becomes equal to atmospheric pressure, the liquid boils. From fig. 8.2 it can be seen that the pressure of saturated vapor naturally increases with increasing temperature. At the same external pressure, liquids boil at different temperatures, since they have unequal vapor pressures.

acetone ethanol water

Temperature, °C

|

Rice. 8.2 Dependence of saturated vapor pressure (P × 10-5 Pa.) of liquid on temperature (acetone, ethyl alcohol, water - respectively).

If you change the external pressure, the boiling point of the liquid will change. With an increase in external pressure, the boiling point increases, and with a decrease (vacuum), it decreases. At a certain external pressure, a liquid can boil at room temperature.

The dependence of saturated vapor pressure on temperature is expressed by the Clausius-Clapeyron equation

, (8.1)

, (8.1)

where is the molar enthalpy of vaporization, ![]() ; - molar change in volume during evaporation, equal to .

; - molar change in volume during evaporation, equal to .

When a liquid evaporates, the volume of the vapor phase changes sharply compared to the liquid phase. So, during the evaporation of 1 water at 25 ° C and a pressure of 760 mm Hg. Art. 1244 pairs are formed, i.e. volume increased by 1244 times. Therefore, in the equation, the volume of liquid can be neglected: ![]() .

.

. (8.2)

. (8.2)

Taking into account the Mendeleev–Clapeyron equation and then

. (8.3)

. (8.3)

Integration of equation (8.3) leads to the formula

. (8.4)

. (8.4)

This formula bears the name of two scientists - Clausius and Clapeyron, who derived it from various starting positions.

The Clausius–Clapeyron formula applies to all phase transitions, including melting, evaporation, and dissolution of matter.

The heat of vaporization of a liquid is the amount of heat absorbed by the liquid during isothermal evaporation. A distinction is made between the molar heat of vaporization and the specific heat of vaporization (related to 1 g of liquid). The higher the heat of vaporization, the more slowly the liquid, other things being equal, evaporates, since the molecules have to overcome large forces of intermolecular interaction.

The comparison of heats of vaporization can be simpler if they are considered at a constant temperature.

Trouton's rule is widely used to determine: the molar heat of evaporation at atmospheric pressure (P = const) of various liquids is directly proportional to their boiling point Tboil

or

or ![]()

The coefficient of proportionality is called the Trouton coefficient and for most normal (non-associated) liquids it is 88.2 - 92.4 ![]() .

.

The heat of vaporization of a given liquid depends on the temperature. As the temperature rises, it decreases and at the critical temperature it becomes equal to zero.

In engineering calculations, the empirical Antoine equation is used

, (8.5)

, (8.5)

where A, B, are constants characterizing the substance.

The found dependences of saturated steam pressure on temperature are used in fire engineering calculations to calculate the steam concentration (; %), temperature limits of flame propagation

.

.

Under fire conditions, liquids evaporate into the environment. The rate of evaporation of the liquid in this case determines the rate of its burnout. In this case, the evaporation rate is decisively influenced by the amount of heat coming from the combustion zone.

The rate of burnout of liquids is not constant. It depends on the initial temperature of the liquid, the diameter of the tank, the liquid level in it, wind speed, etc.

Saturated vapor pressure over solutions of infinitely miscible liquids

In practice, numerous solutions are widely used, consisting of two or more liquids that are readily soluble in each other. The simplest are mixtures (solutions) consisting of two liquids - binary mixtures. The patterns found for such mixtures can also be used for more complex ones. Such binary mixtures include: benzene-toluene, alcohol-ether, acetone-water, alcohol-water, etc. In this case, the vapor phase contains both components. The saturated vapor pressure of the mixture will be the sum of the partial pressures of the components. Since the transition of a solvent from a mixture to a vapor state, expressed by its partial pressure, is the more significant, the greater the content of its molecules in solution, Raoult found that “the partial pressure of a saturated vapor of a solvent over a solution is equal to the product of the saturated vapor pressure over a pure solvent at the same temperature to its mole fraction in solution":

![]() , (8.6)

, (8.6)

where is the saturated vapor pressure of the solvent over the mixture; - pressure of saturated steam over a pure solvent; N is the mole fraction of the solvent in the mixture.

Equation (8.6) is mathematical expression Raoult's law. The same expression is used to describe the behavior of a volatile solute (the second component of a binary system).

METHOD FOR CALCULATION OF EVAPORATION PARAMETERS OF COMBUSTIBLE UNHEATED LIQUIDS AND LIQUEFIED HYDROCARBON GASES

I.1 Evaporation rate W, kg / (s m 2), determined by reference and experimental data. For flammable liquids not heated above ambient temperature, in the absence of data, it is allowed to calculate W according to formula 1)

W \u003d 10 -6 h p n, (I.1)

where h - coefficient taken according to table I.1 depending on the speed and temperature of the air flow over the evaporation surface;

M - molar mass, g/mol;

p n - saturated vapor pressure at the calculated liquid temperature t p, determined from reference data, kPa.

Table I.1

| Air flow rate in the room, m/s | The value of the coefficient h at temperature t, ° С, air in the room | ||||

| 10 | 15 | 20 | 30 | 35 | |

| 0,0 | 1,0 | 1,0 | 1,0 | 1,0 | 1,0 |

| 0,1 | 3,0 | 2,6 | 2,4 | 1,8 | 1,6 |

| 0,2 | 4,6 | 3,8 | 3,5 | 2,4 | 2,3 |

| 0,5 | 6,6 | 5,7 | 5,4 | 3,6 | 3,2 |

| 1,0 | 10,0 | 8,7 | 7,7 | 5,6 | 4,6 |

I.2 For liquefied hydrocarbon gases (LHG), in the absence of data, it is allowed to calculate the specific mass of vapors of evaporated LHG m LHG, kg/m 2, according to formula 1)

![]() , (AND 2)

, (AND 2)

1) The formula is applicable at the temperature of the underlying surface from minus 50 to plus 40 °C.

where M - molar mass of LPG, kg/mol;

L is the molar heat of vaporization of LPG at the initial temperature of LPG T W, J/mol;

T 0 - the initial temperature of the material, on the surface of which LPG is spilled, corresponding to the calculated temperature t p , K;

T W - initial temperature of LPG, K;

l tv - coefficient of thermal conductivity of the material on the surface of which LPG is poured, W / (m K);

a - effective coefficient of thermal diffusivity of the material, on the surface of which LPG is spilled, equal to 8.4· 10 -8 m 2 / s;

t - current time, s, taken equal to the time of complete evaporation of LPG, but not more than 3600 s;

Reynolds number (n - air flow velocity, m/s; d- characteristic size of the LPG strait, m;

u in - kinematic viscosity of air at the design temperature t p, m 2 / s);

l in - coefficient of thermal conductivity of air at the design temperature t p, W / (m K).

Examples - Calculation of evaporation parameters for flammable unheated liquids and liquefied hydrocarbon gases

1 Determine the mass of acetone vapor entering the volume of the room as a result of emergency depressurization of the apparatus.

Data for calculation

In a room with a floor area of 50 m 2, an apparatus with acetone was installed with a maximum volume of V ap = 3 m 3. Acetone enters the apparatus by gravity through a pipeline with a diameter d= 0.05 m with flow q, equal to 2 10 -3 m 3 / s. The length of the pressure pipeline section from the tank to the manual valve l 1 = 2 m. The length of the section of the outlet pipeline with a diameter d= 0.05 m from the tank to the manual valve L 2 is equal to 1 m. The air flow rate in the room with general ventilation operating is 0.2 m / s. The air temperature in the room t p \u003d 20 ° C. The density r of acetone at a given temperature is 792 kg / m 3. The saturated vapor pressure of acetone p a at t p is 24.54 kPa.

The volume of acetone released from the pressure pipeline, V n.t is

where t is the estimated pipeline shutdown time, equal to 300 s (with manual shutdown).

The volume of acetone released from the discharge pipeline V from is

The volume of acetone entering the room

V a \u003d V an + V n.t + V from \u003d 3 + 6.04 10 -1 + 1.96 10 -3 \u003d 6.600 m 3.

Based on the fact that 1 liter of acetone is spilled on 1 m 2 of the floor area, the calculated evaporation area S p \u003d 3600 m 2 of acetone will exceed the floor area of the room. Therefore, the floor area of the room equal to 50 m 2 is taken as the area of evaporation of acetone.

The evaporation rate is equal to:

W isp \u003d 10 -6 3.5 24.54 \u003d 0.655 10 -3 kg / (s m 2).

The mass of acetone vapors generated during emergency depressurization of the apparatus t, kg will be equal to

t \u003d 0.655 10 -3 50 3600 \u003d 117.9 kg.

2 Determine the mass of gaseous ethylene formed during the evaporation of the spill of liquefied ethylene in conditions of emergency depressurization of the tank.

Data for calculation

An isothermal liquefied ethylene tank with a volume of V i.r.e = 10000 m 3 is installed in a concrete dike with a free area S vol = 5184 m 2 and a flanging height H vol = 2.2 m. The degree of filling of the reservoir a = 0.95.

The input of the pipeline for supplying liquefied ethylene into the tank is made from above, and the output of the outlet pipeline is from below.

The diameter of the discharge pipeline d tp = 0.25 m. The length of the pipeline section from the reservoir to the automatic valve, the probability of failure of which exceeds 10 -6 per year and the redundancy of its elements is not provided, L= 1 m. The maximum flow rate of liquefied ethylene in the issuance mode G l.e = 3.1944 kg / s. Density of liquefied ethylene r l.e at operating temperature T eq\u003d 169.5 K is equal to 568 kg / m 3. Density of gaseous ethylene rg.e at T eq equal to 2.0204 kg / m 3. Molar mass of liquefied ethylene M zh.e = 28 10 -3 kg/mol. Molar heat of vaporization of liquefied ethylene L and cn at T eq it is equal to 1.344 10 4 J/mol. The temperature of concrete is equal to the maximum possible air temperature in the corresponding climatic zone T b = 309 K. The coefficient of thermal conductivity of concrete l b = 1.5 W / (m K). Thermal diffusivity of concrete a\u003d 8.4 10 -8 m 2 / s. The minimum air flow velocity u min = 0 m/s, and the maximum for a given climatic zone u max = 5 m/s. The kinematic viscosity of air n at the calculated air temperature for a given climatic zone t p \u003d 36 ° C is 1.64 10 -5 m 2 / s. The coefficient of thermal conductivity of air l in at t p is 2.74 10 -2 W / (m K).

With the destruction of the isothermal tank, the volume of liquefied ethylene will be

Free dike volume V about = 5184 2.2 = 11404.8 m 3.

Due to the fact that V zh.e< V об примем за площадь испарения S исп свободную площадь обвалования S об, равную 5184 м 2 .

Then the mass of evaporated ethylene m.e. from the area of the strait at an air flow velocity u = 5 m/s is calculated by the formula (I.2)

Mass m ee at u = 0 m/s will be 528039 kg.

The simplest representative of ketones. Colorless, easily mobile, volatile liquid with a pungent characteristic odor. It is completely miscible with water and most organic solvents. Acetone dissolves well organic matter(cellulose acetate and nitrocellulose, fats, wax, rubber, etc.), as well as a number of salts (calcium chloride, potassium iodide). It is one of the metabolites produced by the human body.

Application of acetone:

In the synthesis of polycarbonates, polyurethanes and epoxy resins;

In the production of varnishes;

In the production of explosives;

In the production of medicines;

In film adhesives as a solvent for cellulose acetate;

Component for cleaning surfaces in various production processes;

It is widely used for storing acetylene, which cannot be stored under pressure in its pure form due to the risk of explosion (for this, containers with porous material impregnated with acetone are used. 1 liter of acetone dissolves up to 250 liters of acetylene).

Danger to humans:

Hazard from single exposure to high concentrations of acetone. Vapor irritates eyes and respiratory tract. The substance may cause effects on the central nervous system, liver, kidneys, gastrointestinal tract. The substance can be absorbed into the body by inhalation and through the skin. Prolonged skin contact may cause dermatitis. The substance may have effects on the blood and bone marrow. Due to the high toxicity in Europe, methyl ethyl ketone is more commonly used instead of acetone.

Fire hazard:

Highly flammable. Acetone is classified as class 3.1 flammable liquid with a flash point of less than +23 degrees C. Avoid open flames, sparks and smoking. A mixture of acetone vapors with air is explosive. Hazardous air pollution will be reached quite quickly when this substance evaporates at 20°C. When spraying - even faster. The vapor is heavier than air and can travel along the ground. The substance may form explosive peroxides on contact with strong oxidants such as acetic acid, nitric acid, hydrogen peroxide. Reacts with chloroform and bromoform under normal conditions causing fire and explosion hazard. Acetone is aggressive towards some types of plastic.