Every tenth trolleybus in St. Petersburg will receive autonomous running from Liotech

24.07.17 09:10 Liotech-Innovations LLC will supply 66 car kits of lithium-ion batteries (LIAB) for the Russian trolleybus manufacturer Trolza.

The project is being implemented under a contract between Trolza and the Transport Committee of St. Petersburg for the supply of trolleybuses with increased autonomous running in order to upgrade the city's electric transport.

Now there are 46 operating in the city trolleybus routes, and the fleet is more than 600 trolleybuses. Thus, 10% of the city's trolleybus fleet will be equipped with lithium-ion batteries manufactured by Liotech-Innovations LLC. All machines to be delivered under the contract have a stock autonomous running for 7.5 km.

“The increase in the number of trolleybuses with an extended autonomous run on Russian roads is an important stage in the development of electric transport, allowing Russia to create competencies in the development and production of drives with an energy intensity of up to 100 kWh, and subsequently move on to the production of more powerful and energy-intensive (200–400 kW* h) drives for use in electric buses and other powerful machines. It is also convenient for urban operating companies - they get the opportunity to test vehicles on an autonomous electric run now and use this experience in the future when introducing electric buses,” said Vladimir Kozlov, Managing Director for Investment Activities of RUSNANO Management Company.

According to forecasts, by 2025 the total capacity of energy storage devices used for urban transport will be more than 10 GWh. Under the contract, Liotech-Innovations manufactures and supplies not only lithium-ion batteries, but also a top-level technical solution: a battery that includes a specially designed housing, a control and temperature control system. On the this moment Liotech is the center of Russian competencies in the mass production of lithium-ion cells and batteries based on them.

“For us, the development of cooperation with Trolza is a recognition of the quality and effectiveness of our products. In addition to 66 sets for Trolza trolleybuses for St. Petersburg, a large batch of trolleybuses with an autonomous range for operation in the South will be delivered in the near future. federal district. We are not going to rest on our laurels and are actively presenting the products of Liotech-Innovations LLC at leading international technology exhibitions. So, according to the results of work for the year, the number of electric vehicles with increased autonomous running, equipped with LIAB produced by Liotech-Innovations, will be about 150 units,” said Valery Yarmoshchuk, General Director of Liotech-Innovations LLC.

Liotech delivers to the energy market. At the beginning of 2017, another RUSNANO portfolio company launched a hybrid power plant (HPP) in the village of Menza in the Trans-Baikal Territory. ASPU consists of solar modules with a total capacity of 120 kW, two diesel generators of 200 kW each. As part of the installation, battery cells for an energy storage device with a capacity of 300 kWh manufactured by Liotech were used. It is planned that in 2017 Hevel will build two more hybrid power plants in Transbaikalia, which can also use Liotech energy storage devices as a fully completed product in a container design, including all electronics and a control system (the choice of supplier will be determined after the end of the competition). The Liotech drive will use new developments of the plant with a full guarantee of quality.

Also, Russian manufacturers of commercial vehicles receive requests for the supply of LIAB kits for both electric vehicles, electric buses and special equipment. At the moment, ready-made solutions are being developed for other special equipment, in particular, for the mining industry.

“Rain... Fog over the Neva. The lions wet their manes." And in the midst of this landscape... A bus? No, a trolleybus that can move without wires! He visited St. Petersburg, and I took part in his tests.

D hold on tight,” the driver advises, “now I’ll show you the dynamics of acceleration!” She is at the level of a passenger car - although we are talking about a trolleybus that was moving with its bars down!

Let's start with a quote from the reference book "Urban Transport and Traffic Management", published back in 1960. “Trolleybuses (a combination of a trolleybus with a diesel-electric bus) and trolleyaccubuses (where a battery is installed) can be used in the central regions of large cities where the suspension of a contact network is undesirable ... Working on the line mainly as a trolleybus, certain sections of the car will be able to pass with attracted pantograph rods, without requiring a contact wire. The disadvantages of this transport are as follows: the complexity of the power equipment and the high cost.

Since then, more than half a century has passed, and here it is, a trolleyaccubus, or rather, an autonomous trolleybus. Its name is Trolza-5265.02 Megapolis, and the car was brought to St. Petersburg on the eve of the World Cup: it is assumed that these will deliver passengers to the new stadium on Krestovsky Island. The trolleybus line has not been laid there, and it is not environmentally friendly to transport fans by buses, albeit modern ones: “zero exhaust” is in fashion.

But if the electric buses are just being tested, Trolza's "trolleyaccubuses" are already being produced. These were delivered to Tula (16 cars), Nalchik (10 copies) and even Argentina, for the cities of Cordoba and Rosario (7 and 12 pieces, respectively). And in total, by the end of 2017, 101 copies should be produced.

By the way, cars for Rosario were shipped quite recently, in January, and their price is known: about 350 thousand dollars, or more than 20 million rubles. The copy shown in St. Petersburg is somewhat cheaper - about 17 million rubles, which is comparable to the price of a LiAZ gas bus.

The interior resembles low-floor LiAZ buses. It even has room for a guide dog!

And, honestly, if such cars start to walk around St. Petersburg, I will gladly use them! The trolleybus is completely low-floor, and even with the “squatting” (kneeling) system. Wide doors with an active edge (these will not pinch your arms and legs) lead to a spacious and bright salon with an anti-slip floor. It contains diffused diode lighting, which turns on automatically, from the sensor. Double glazing, multi-zone climate control...

Near the wheelchair space there is not only a touch button with backlight and Braille, but also an intercom. There is even room for a guide dog!

The trolleybus is low-floor, but the rear entrance is intricate

And it's warm in the cabin. In a bus, every extra stove is a load on the generator, engine, and cooling system. A trolleybus is a different matter, there is nothing of this in it, only a 550/28 V converter. And since there is more than enough energy in the network, you can literally put a stove under every seat (and in theory, place sockets for charging mobile phones with tablets).

The driver's cabin resembles a pilot's cabin - or the cabin of a ship. The entire space of the front panel is strewn with buttons, the cabin is hung with gadgets, but the most impressive is the instrument panel. Since the machine is equipped with a CAN bus, information from an endless menu is displayed on the display - from the washer level in the tank to the instruction manual with all the electrical circuits.

Of course, there are video cameras and a GLONASS terminal, which is also not easy. Through satellite, the system sees the trolleybus on the route and automatically announces the stops!

It also connects the trolleybus with the fleet and makes it possible not only to remotely monitor the vehicle's systems, but also display messages for the driver - for example, that one of the turn signals is not working.

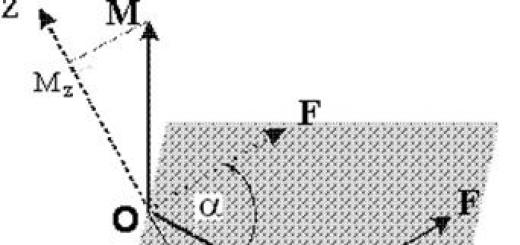

Management is elementary: I pressed the move selection button (forward or backward), pressed the right pedal (not gas, but the chassis) and drove off. Look through the heated windshield, check the situation on the huge mirrors (also heated and electrically adjustable) - and the steering wheels from stop to stop! Acceleration is limited by the "brains": the thrust of the electric motor is huge. Max Speed is also limited to 60 km / h, and an electric retarder helps to slow down - an electrodynamic braking system. Moreover, energy recovery during braking is implemented here: about 20% of the energy spent is returned to the contact network.

Another advantage for the driver is the automatic lifting and lowering of the booms. In the right place, you can, by pressing a button, fold the “horns” - and the trolleybus will turn into an electric bus.

What we, in fact, did for photography near the Rostral columns of Vasilyevsky Island. It’s a pity, with the installation of current collectors on the wires, everything is not so simple: the “horns” can be automatically raised only where there are guides on the contact network. I saw them only in the trolleybus depot. So after our photographing, the driver acted in the old fashioned way: bypassed the trolleybus and “fastened the rigging” with ropes.

But autonomous running is really cool. The car is equipped with two Toshiba lithium-titanate battery packs and it is promised that the trolleybus can travel on them - without a contact network, at full load - 15 kilometers. Can you imagine how convenient it is to go around traffic jams and congestion? Yes, and network breaks are not terrible: all trolleybuses are standing, and this one is going to the delight of passengers!

By the way, Russian batteries from Rosnano-Liotech were installed on earlier copies, but now the property of the Novosibirsk Liotech plant is put up for sale ...

As for other technical features, both bridges are branded ZF. And suspension elements, tires and brake pads are unified with LiAZ buses - which is very convenient for parks where both electric and diesel vehicles operate.

It is also unusual that the electric motor, its control device, converter, compressor are of domestic production. The compressor, by the way, is screw - silent and vibration-free.

The main place in the rear compartment is occupied by the compressor (it is installed on the right)

In general, the trolleybus is very quiet, it's a pity, the power steering is buzzing. According to St. Petersburg experts, it would be more logical to install an electric amplifier: it is simpler, quieter and not afraid of frost.

They also noted other shortcomings. First, batteries weighing almost 700 kg, located on the roof, are not very good: they greatly increase the center of gravity and affect stability. Maybe it's worth sacrificing low-floor and installing batteries under the floor at the back, as is already done in Europe?

Traction batteries are located on the roof under the casing with the inscription "do not step"

Secondly, the rear corners of the body with built-in lighting are strangely made: they are plastic and glued to the base. What will it be like to fix them even after a small accident?

It is not clear why the vents are glued into the double-glazed windows: leaving the line with a non-working air conditioner is prohibited! Finally, there are no mentioned charging sockets in the cabin, which passengers would only be happy about.

Be that as it may, during the tests, Megapolis successfully covered eight kilometers “on batteries” along the route intended to deliver spectators to the stadium. And there is every chance that the fans will go to Krestovsky Island in just such cars - not cheap, but fast, quiet, environmentally friendly and even capable of moving without wires.

| Passport data | |

|---|---|

| Model | Trolza-5265.02 Megapolis |

| Number of places | |

| general | 100 |

| for sitting | 35-37 |

| Overall dimensions, mm | |

| length | 12335 |

| width | 2550 |

| height | 3470 |

| Curb weight, kg | 10580 |

| Gross weight, kg | 17380 |

| electric motor | DTA-1U1 AC |

| Max. power, kWt | up to 180 |

| Battery type | lithium titanate |

| Capacity, Ah | 80 |

| Max. speed, km/h | 60 |

Materials for the article:

- Brief feasibility study of the project (S.I. Parfenov, General Director of OAO Sibeltransservice)

- Letter from the President of MAP GET A.V. Miroshnik and the chairman of the MVK, the General Director of NIIGET V.A. Golubev in support of the project

1. Brief rationale for the development of electric transport

Frequent energy crises, constant outpacing other energy sources, rising prices for hydrocarbon energy sources, disruptions in their supply, lower coefficient useful action, the rapidly increasing decline in the demand for hydrocarbon fuels to their reserves are the main reasons for the world's leading automotive industry flagships of the USA, Japan, Germany, France, China and Korea to conduct intensive development to create vehicles of mass demand, powered by electric traction.

Experience in the development of hybrid types of vehicles is also accumulating in the Russian Federation. The companies Ruselprom, AvtoVAZ, the Onexim group with a hybrid based on the E-center, and others not only participate in the design and development of such vehicles, but also create prototypes. For more than ten years, the Novosibirsk State Technical University (NSTU) has been studying the operating modes of hybrid vehicles. According to the experts of this university, in the next 10-20 years, electric vehicles and electric buses will find the widest practical use in the world.

The main task in the creation of electric vehicles and electric buses is the production of powerful and capacious energy storage devices and charging power stations. An intermediate vehicle between a bus and an electric bus should be a trolleybus with a large autonomous course, which will be used even in the mass use of electric buses due to economic feasibility, since it will always be cheaper than electric buses. At the first stage of the appearance of electric buses, the functions of charging stations can be performed by the existing contact-cable lines of urban electric transport.

In this regard, it is already necessary to begin work on the preparation of the energy systems of the UET and the country as a whole, as well as service centers, specialists, and the entire infrastructure associated with urban electric transport.

2. Existing sources of power plants for electric vehicles and electric buses

Three types of possible sources of autonomous power supply for electric vehicles are common in the world: superbatteries, supercapacitors and diesel power plants. However, these sources were not found. wide application:

- Electric buses on supercapacitors are quickly charged and quickly discharged, the distance from the charging station is possible within 2-3 km.

- Electric buses powered by lithium-ion batteries are expensive ($500,000-700,000). The weight of the battery is 3.5 tons, the travel distance without recharging is about 150-180 km. Charging time with high currents is 1.5-2 hours, which requires developed powerful electrical cable lines.

- Electric buses with a diesel power plant do not solve the problem of ecology and are inefficient from an energy point of view, since an increase in the efficiency of diesel fuel combustion is destroyed by losses due to the efficiency of the power plant.

Nevertheless, according to most experts, the future of the automotive industry lies with electric modes of transport. With the discovery at the beginning of this century of high conductivity of lithium iron phosphate, in combination with nanotechnologies for depositing carbon on the cathode, new prospects opened up in the development of electric vehicles.

3. Description of the proposed project

At this stage scientific and technological development the main issues of the use of energy storage devices (NE) in transport are related to the justification and choice of an energy source, as well as the modes of its operation.

AT Novosibirsk region this year, the construction of a large plant for the production of power lithium-ion batteries, the manufacture of which is based on nanotechnology for applying carbon to the cathode, is being completed. A scientific and industrial group was created in the city under the leadership of the First Deputy Mayor of Novosibirsk A.E. Ksenzov. This group includes specialists and scientific personnel of the Novosibirsk Plant of Chemical Concentrates, the Research Institute of Chemistry solid body Siberian Branch Russian Academy Sciences, Novosibirsk State technical university, Department of Passenger Transportation of the Mayor's Office, NPF ARS-TERM LLC, NPF Irbis LLC, Sibeltransservice OJSC, Siberian Trolleybus LLC and other organizations. As part of the work of this group, a prototype was created at the production base of OAO Sibeltransservice vehicle, capable of moving in the modes of a trolleybus and an electric bus powered by a battery of lithium-ion batteries.

Rice. 1. Trolleybus ST-6217 with increased autonomous running resource

Rice. 2. Appearance trolleybus

Rice. 3. Front view of the trolleybus

Rice. 4. Boom catchers of ST-6217 trolleybus

Rice. 5. Placement of electrical equipment on the roof of the trolleybus

The mileage of the prototype in the electric bus mode was 39 km with the curb weight and 28 km with the full weight of the trolleybus. After running in the electric bus mode, the trolleybus, moving under the contact network, recharges the batteries. When braking in the mode of a trolley bus and an electric bus, the kinetic energy is converted into electrical energy and goes to recharge the batteries.

The large autonomous running of the trolleybus is ensured by the installation of a battery of lithium-ion batteries (LIA) under the floor, consisting of 168 batteries. Battery capacity 90 Ah. Battery weight - 480 kg. The price of a set of batteries is 870,000 rubles. The estimated price of the ST-6217 trolleybus with such a power plant manufactured by OAO Sibeltransservice is 7.5 million rubles. Battery life depends on operating conditions. Operating recommendations are given by the trolleybus manufacturer after familiarization with the route and working conditions. Battery life depends on the number of cycles, and the number of cycles depends on the degree of discharge during the cycles. Under operating conditions, when the battery discharge reaches up to 60% (deviation from the contact network by 15 km), the service life will be 8000-10000 cycles or 7 years based on the length of the return trip of 37 km (including 15 km without a contact network) with average work of 12 hours and operating speed of 16 km / h - 12 / (37:16) = 5 cycles per day. The shorter the autonomous range, the longer the battery life. So, if the path without a contact network is equal to 10 km during one return flight, then the battery life will be 10.5 years. These calculations are made for the total mass of the trolleybus during the battery life, that is, the actual operating conditions are much easier. All performance indicators can be increased by choosing more capacious batteries, but this will lead to a rise in the cost of the vehicle.

It is also important to note that the prototype ST-6217 trolleybus produced has the most optimal weight and cost of batteries per 1 ton*km of vehicle run.

An important economic indicator is the durability of LIB operation.

Rice. 6. Rear of the trolleybus

Rice. 7. Rear of the trolleybus

Rice. 8. Back door

Rice. 9. Rear door passenger counting system

Rice. 10. Indicator of the number of passengers entering and exiting

Rice. 11. Passenger information system

Rice. 12. Dashboard

Rice. 13. Dashboard

Rice. 14. Electronic speedometer

Rice. 15. Surveillance equipment for the interior of a trolleybus

4. Advantages of the proposed project

4.1. Electric rolling stock acquires the property of autonomous running and increased maneuverability, which will allow:

- drive through the special parts of the contact network (arrows, intersections) at high speed with the pantographs lowered, remove the contact network and its special parts from individual streets and squares;

- extend existing trolleybus routes by 10-15 km;

- to expand the trolleybus route network due to the possibility of moving from one trolleybus line to another.

4.2. Buses on routes that have a partly common track with trolleybuses can be replaced by trolleybuses.

4.3. While moving under the contact network, a trolleybus with LIB is a permanent consumer of energy recuperated into the network by the trolleybus itself and other trolleybuses during braking. This will save up to 20% of traction electricity. The total energy savings, taking into account savings in the elimination of ballast starting-braking resistances, according to the most conservative estimates, will be about 50%.

4.4. The development of the route network of an environmentally friendly mode of transport will not require any financial costs (there is no need for contact-cable lines and traction substations). An opportunity is provided to increase the energy and economic efficiency of the use of existing contact-cable lines and structures of the UET.

4.5. An opportunity is provided for the creation and development of infrastructure that ensures the operation of future electric vehicles and electric buses.

4.6. The energy systems of the regions and the country will be assessed, organizational and technical measures will be developed for their most efficient operation and preparation for the mass operation of electric transport.

5. Opportunities for saving energy resources, improving the energy efficiency of energy systems

The introduction of trolleybuses with LIB and energy-saving electronic drives will significantly save the generated electricity, as well as increase the energy efficiency of the existing contact-cable lines of the UET, energy systems, power plants, the entire energy system of the country, will serve as an impetus for its development, and at the same time the development of the country's economy.

5.1. Energy savings through recuperation

Currently, electronically driven trolleybuses can recuperate energy into the grid, converting the kinetic energy of movement into electrical energy. However, the consumption of this energy is possible only if the process of energy consumption by another trolleybus located in this section of the contact network (feeder) coincides temporarily. Practical savings in calculations using probabilistic methods are estimated at 15-20% of the total recuperated energy. In trolleybuses with rheostat-contactor control systems, energy recovery into the network is generally impossible, and when the kinetic energy of the trolleybus acquired during acceleration is extinguished, the currents generated by the engine are quenched by braking resistances and turn into heat. Braking currents in existing models of trolleybuses range from 0 to 200 A. Considering that a trolleybus with a LIB consumes a charge current of 45A, we can say that being in singular at the feeder, a trolleybus with LIB will save 5-6% of its own electricity consumed for overclocking. In case of absence negative impact on the cathodes of peak charging currents or being on the feeder of 5-6 trolleybuses, this saving can be increased to 25-30%.

According to the MCP "Gorelectrotransport" of Novosibirsk, the consumption per 1 km of run for a trolleybus is 3.2 kWh, with only 20% of the rolling stock with energy-efficient electronic drives. Considering that a trolleybus with an energy-efficient drive consumes 30% less electricity than trolleybuses with a rheostat-contactor control system, we can say that a trolleybus with an electronic control system consumes 2.4 kWh per 1 km of run, taking into account losses in the lines. Therefore, under the most favorable set of circumstances, a trolleybus with LIB can save an additional 0.6 kWh per 1 km of run. That is, the cost of a trolleybus with LIB, taking into account losses in lines per 1 km, is 1.8 kWh, without taking into account losses - 1.2 kWh.

Considering that a trolleybus travels 50-60 thousand km a year, additional savings will amount to 50,000 * 0.6 * 2 rubles. 50 kop. = 75,000 rubles.

5.2. Savings by increasing the efficiency of power systems, contact cable lines are subject to a deeper analysis of the existing indicators of their operation and should be carried out after special calculations of power systems.

5.3. Saving energy resources by replacing part of the buses with trolleybuses with a large autonomous course. Replacing a bus that has a 50-60% common route with a trolleybus route network is economical due to the following factors:

- allows you to save on the energy component of the cost of passenger transportation;

- allows you to increase the density of the rolling stock at the feeder and thereby increase energy savings by increasing the consumption of regenerated electricity during braking;

- improves the energy efficiency of existing energy systems in general;

- reduces operating costs due to greater reliability and durability of the trolleybus.

According to the norms for the consumption of gasoline and diesel fuel, established by the orders of the Ministry of Transport of Russia No. AM-23-R of March 14, 2008, the fuel consumption of LiAZ-5256 buses is an average of 45 liters per 100 km. The electricity consumption of a trolleybus, taking into account the energy consumption for the LIB charge, is 1.8 kWh per 1 km of run.

The energy component per 1 km of run by the bus is 45 l * 25 rubles. / 100 km = 11 rubles. 25 kop.

The energy component of a trolleybus per 1 km of run will be 1.8 kWh * 2.5 rubles. = 4 rubles. 50 kop.

Savings per year on one vehicle will be: (11.25 - 4.5) * 50,000 km = 337,500 rubles.

Only due to the saved electricity, the batteries will pay off in 2.6 years, and the total cost of increasing the cost of a trolleybus due to the installation of LIB in the amount of 1.6 million rubles. payback in 4.75 years.

The given calculated values do not take into account the savings achieved by increasing the efficiency of the use of energy systems and fixed production assets. As the electric rolling stock grows, the cost of transportation will fall due to an increase in the efficiency of the use of fixed production assets of the UET.

6. Purpose of the project

The project has a multi-purpose value. Goals are divided into national and local importance.

The national goals are:

- preparation of various power systems for the mass operation of electric transport;

- development of an efficient, economical, reliable, competitive vehicle on world markets, which is a transitional model between a trolleybus and an electric bus;

- curbing the growth in the cost of transporting passengers on urban routes and, as a result, curbing tariffs for transport services, and at the same time curbing social tension in the country's cities.

The goals of local importance are:

- the possibility of extending existing trolleybus routes without building contact-cable lines and traction substations by 10-15 km, increasing the share of environmentally friendly, cost-effective transport;

- the possibility of replacing part of the buses on city routes with trolleybuses;

- the possibility of building efficient structural outbound trolleybus lines in medium-sized cities;

- the possibility of improving the energy efficiency of existing energy supply systems and the economic efficiency of fixed assets of the UET;

- development of a network of charging stations for future electric buses and electric vehicles based on the existing power systems of the GET.

7. Consumers and characteristics of marketing policy

The consumers of trolleybuses with a large autonomous course may be the administrations of cities that already have trolleybus networks. It is planned to replace morally and physically obsolete rolling stock, taking into account the need to use trolleybuses in electric bus modes (autonomous running). In Russia, 10 thousand trolleybuses are operated in 87 cities, 5.5 thousand of them need to be replaced in the order of natural reproduction.

A double increase in the inventory fleet of trolleybuses is expected due to an increase in the length of routes without the construction of a contact network and the replacement of part of the buses with trolleybuses.

The possibility of exporting trolleybuses to countries that already have trolleybuses seems quite voluminous. We consider it possible to export trolleybus sets to countries where our country is building nuclear power plants.

The estimated volume of annual sales of trolleybuses with a large autonomous course is 1000-1500 units in the amount of 7.5-11.5 billion rubles.

However, it should be noted that the acquisition of rolling stock without state support is largely limited and may lead to a complete shutdown of the domestic auto industry plants.

8. Project promotion plan

The achieved indicators of the ST-6217 prototype trolleybus allow us to assert the possibility of its wide application on urban routes.

Considering the scale of novelty, originality of the created vehicle and the practical difficulty of replacing the existing fleet of trolleybuses with trolleybuses with a large autonomous course, further promotion of the project requires fundamental decisions at the first stage and should be carried out in two directions:

- creation of new municipal trolleybus routes with sections without a contact network;

- creation of private trolleybus routes, or routes with mixed forms of ownership.

The increase in electric vehicles through the use of trolleybuses with a large autonomous course should have a program approach and should include the following main sections.

- calculation of the capacity of existing contact cable lines, determination of technical measures that increase them throughput;

- creation of complex route schemes in major cities and their agglomerations;

- creation of real routes using trolleybuses with a large autonomous course;

- pilot operation of trolleybuses with a large autonomous course, the creation of a more advanced electric vehicle.

All these steps can be carried out sequentially. First, in one city, then within the Siberian and Far Eastern Federal Districts and on a national scale.

To achieve real practical results, it is necessary federal program on the development of urban electric transport as the main mode of transport in urban passenger traffic. The program should include measures that will significantly increase the operating speed of trams and trolleybuses, the main of which should be the construction of transport interchanges in large industrial centers of the country.

: “An electric bus in a fifteen-year cycle is cheaper than a trolleybus by almost 10% due to the fact that the price of a trolleybus correctly includes the cost of the car, and the service, and the costs that we spend, and the maintenance of the contact network, which some of our critics simply do not consider, removing from the account." Is it really? Let's try to figure it out.

To begin with, it is worth understanding what figures for electric buses generally exist in the public domain and how Liksutov can operate with them. First of all, these are data on the purchase of electric buses and charging stations. For example, let's take the purchase of KamAZ trucks for 6.3 billion rubles. According to it, one electric bus costs about 33 million rubles. In the same purchase, the cost of maintenance per kilometer for 2018 is calculated - 22.22 rubles.

The cost of purchasing an electric bus and charging. Source: public procurement website

The cost of purchasing an electric bus and charging. Source: public procurement website

What about trolleybuses? For example, autonomous trolleybuses are successfully operating in St. Petersburg, and this is exactly the public transport that Moscow needs, and not electric buses. In terms of purchases, the cost of such a trolleybus is about 20 million rubles. Already there is a difference of 13 million. The cost of service per kilometer for a trolley bus as a whole, not only for St. Petersburg, cannot cost more than 20 rubles (according to a source from Mosgortrans), there are simply no life cycle contracts for a higher price, and on average it is about 18 rubles per kilometer. Even if we take a bus example, which according to statistics is clearly more expensive than a trolleybus, the life cycle cost of LiAZ in bus depot 17 is 14 rubles per kilometer, even taking into account the inclusion of major repairs in the cost, it cannot exceed 17 rubles. And even if we take the maximum allowable 20 rubles per kilometer, it still comes out cheaper than an electric bus.

Electric bus maintenance cost. Source: public procurement website

Now about the contact network, which “critics are discounting”, its antonym in our case will be charging stations for electric buses, which cost almost 13 million to purchase. To find out the cost of the contact network, let's take a recent tender for its reconstruction in Polyanka under the My Street program. The cost of almost complete reconstruction amounted to 8 million rubles per kilometer.

The cost of rebuilding the contact network in Polyanka. Source: public procurement website

These are new wires, spare parts, fittings. Let's try to use these figures to calculate how much the trolleybus infrastructure on the current route 73 will cost. Now there are four charging stations installed on it, but only two of them are working, and the other two are not even connected. When the time comes for electric buses to charge, queues form near the charging stations, meaning that the current number of charging stations is not enough. For the stable operation of the route, 60 electric buses are needed, with planned use, these are 15-20 charging stations, but with current breakdowns and problems, 34 charging stations are needed to have a reserve. The length of route 73 (according to the register) is 24.7 km, 195.4 million rubles will be needed for the overhaul of the trolleybus infrastructure. And it will be a fully and stably functioning route. For electric buses, as we calculated, 34 charging stations are needed, that is, almost 441 million rubles. At the same time, the service life of the contact network is 15-20 years, but in fact it can serve up to 30 years if you change small parts that cost a penny on a general scale. Therefore, this is a long-term and effective investment, and even a network built from scratch costs much less, requires virtually no maintenance and lasts much longer, unlike electric bus charging stations.

In addition, today's self-driving trolleybuses, like those from St. Petersburg, do not need wires throughout the entire route, even a little less than half is enough, that is, this is even less money. And given the constant breakdowns of charging stations due to imperfect technology, backup and emergency stations are needed.

The cost of a St. Petersburg trolleybus with autonomous running. Source: public procurement website

According to our sources from Mosgortrans, 5,000 rubles a month is spent on maintaining a kilometer of a contact network - mainly replacing small parts that deteriorate due to the climate, and maintaining a charging station costs 44,600 rubles per kilometer per month. Again, for the stable operation of route 73, 1.44 million rubles a year must be spent on servicing the contact network, and 18.2 million rubles a year on servicing charging stations. Of course, the trolleybus infrastructure is much cheaper, and we do not take into account the cost of installing charging stations, since these data simply do not exist. You can object, because you need to calculate the cost of the substation, which should feed the wires. But the fact is that the substations feed not only the contact network of trolleybuses, but also the charging stations of electric buses, so its cost does not matter for comparison. The argument about the high cost of the network disappears.

Charging maintenance cost. Source: public procurement website

As you know, the electric bus runs not only on electricity. Inside there is a diesel stove for heating. Its approximate fuel consumption is 3.5-4 liters per hour, that is, in 15-16 hours of operation, the electric bus turns into the equivalent of a small car and almost half of the bus. These are additional expenses for refueling and for the fuel itself. And let's not even mention the promised "green mode of transport."

The main part of the expenses in any enterprise is staff salaries. According to the response of Mosgortrans at public hearings, it is planned to produce 34 electric buses instead of 22 trolleybuses on route 73 in order to reduce the waiting interval between them - electric buses need time to recharge. This is not only a big expense due to the use of more cars, but also a much higher cost for the wages of drivers. Even if we really assume that the electric bus is 10% cheaper, all these calculations crumble only from an increase in the number of cars by 12 units and a larger payroll. Drivers are certainly fine, in fact, they are paid for idle time while waiting for charging, but is this an efficient use of funds?

All these are numbers, let's move on to practice. And it shows that such a non-working technology in the future may require even more money for repairs and improvements. Not a single GOST for charging stations exists, it is not clear how they will be coordinated. Mosgortrans refers to the fact that it is new technology and there are no requirements for it, but it is not. There are GOSTs for electrical installations, so the situation is such that the installed stations are essentially illegal. And since there is no certification information on them, it is impossible to find out how much energy they consume. But, judging by how they heat up and break down, unable to withstand the voltage, they consume more than they can. They were installed as strangely as possible - practically on the roadway, if snow falls and a snowplow drives, it will either demolish the station or fill it with snow, which will make it difficult to charge the electric bus, or simply damage it. In addition, according to information from cable laying specialists, the charging stations in Bibirevo that are now standing are powered by trolleybus wires, since the cable was not laid there, and at VDNKh everything was flooded with water during the laying of the cable, several cars were engaged in pumping water, but could not pump out all water. In fact, the cable is partially in the water. At any time, this can lead to an accident and the next expense for repairs.

Chinese batteries on the roofs of electric buses overheat, so it upper part are simply removed. Whether this can lead to an emergency if it rains or snows is not entirely clear, but a breakdown or even an explosion of the battery from overheating is a very likely tragedy. The electric buses do not have wiring harnesses, so only two of them have air conditioning. This, again, is additional spending on refinement and repair due to a fictitious non-working technology. I remember the story when Liksutov was going to fire people for non-working air conditioners (according to our information, no one has been fired yet). Where are the layoffs for a completely non-working electric bus?

In the same way, money that was spent on the reconstruction of the contact network is buried in the sand, and later it was decided to launch an electric bus on these routes. For example, as on the 76th trolleybus route. In 2016, poles and wires were replaced there, but now it is planned to launch an electric bus there. Under the program for the reconstruction of outbound highways, the trolleybus infrastructure of the Shchelkovo highway was reconstructed, but route 83 is also going to be changed to an electric bus. Money wasted. And there are a lot of such sites, what kind of savings is there?

In fact, we have untested, raw and inefficient electric bus technology, the calculations for which were carried out in an incomprehensible way. Where do 10% of cheapness come from compared to a trolleybus - it's hard to say, everything is broken down by the figures of Mosgortrans itself. Moreover, the current trolleybus can be made even cheaper and not lose efficiency. For example, if you take inexpensive supports for a contact network, do not use expensive ribbed insulators, when wood has been effectively used all over the world for a long time and there is no need for expensive insulators. Small parts are replaced very often with us, due to the fact that Mosgortrans already buys the cheapest parts, while in Europe more expensive parts are used that do not require constant repairs, but everything comes out much more expensive for us. And all this leads to the fact that the authorities continue to destroy the trolleybus, and do not hesitate to adjust all the numbers to their goals, doing everything so that the trolleybus becomes ineffective in the eyes of the public.

Like this format? Help me write more.