1. Before starting work, inspect the vise, paying special attention to the strength of their fastening to the workbench. 2. Workpieces should be fixed firmly, but by smooth rotation of the screw handle. 3. Do not hit the vise handle with a hammer and increase its length with a pipe. 4. Do not perform rough work on the vice (cutting, straightening or bending) with heavy hammers, as this leads to the rapid destruction of the vice. 5. When releasing the workpiece from the vise, hold it so that it does not fall. 1. Before starting work, inspect the vise, paying special attention to the strength of their fastening to the workbench. 2. Workpieces should be fixed firmly, but by smooth rotation of the screw handle. 3. Do not hit the vise handle with a hammer and increase its length with a pipe. 4. Do not perform rough work on the vice (cutting, straightening or bending) with heavy hammers, as this leads to the rapid destruction of the vice. 5. When releasing the workpiece from the vise, hold it so that it does not fall.

6. It is forbidden to hit hard with a hammer on the vise jaws if the jaws are not clamped. 7. Editing and punching of the workpiece is carried out on the vise anvil. 8. Do not work on the lead screw guard. 9. Do not throw the handle - the steering wheel, but lower it smoothly. (you can injure your hand) 10. At the end of the work, clean the vise from dust and chips, clamp the vise jaws to a gap of 3-5 mm (so that the lead screw does not wear out), lower the handle - the steering wheel down. 6. It is forbidden to hit hard with a hammer on the vise jaws if the jaws are not clamped. 7. Editing and punching of the workpiece is carried out on the vise anvil. 8. Do not work on the lead screw guard. 9. Do not throw the handle - the steering wheel, but lower it smoothly. (you can injure your hand) 10. At the end of the work, clean the vise from dust and chips, clamp the vise jaws to a gap of 3-5 mm (so that the lead screw does not wear out), lower the handle - the steering wheel down.

Organizational part

Target: Creating silence in the classroom, set up students for the lesson

The teacher waits for the students to take their seats, after that he greets them, checks the class composition according to the magazine, appoints two attendants to the lesson

After that, the teacher dictates the topic of the lesson, writing it on the board: "The topic of our today's lesson is metal cutting".

Further says: “Today, each of you must master the techniques of such a plumbing operation as “cutting metal.” To do this, today you will make a steel key for a jigsaw.” The teacher demonstrates the key and says: But before you start studying new material, you must answer the following questions on passed material.

The teacher asks a few short questions.“Guys, before the start of the lesson, you will answer a few questions”

1) What are the methods of processing metals?

2) What are the main types of ferrous metals

3) What are the main types of non-ferrous metals?

4) What are the main properties of metals

Main part

a) Theoretical part.

After updating the knowledge of students, the teacher gives them new material and begins with the definition of a plumbing operation as a felling, which students must subsequently learn

« Metal cutting is a metalwork operation used to remove (cut down) a layer of metal from a workpiece. With the help of cutting, chamfers, sharp edges, scale, burrs and other irregularities are removed.

Then the Teacher gives the concept of the instrument : “This operation is carried out with the help of a chisel and a hammer. Chisel - impact cutting tool for processing metal and stone. The cutting part of the chisel, like other cutting tools, has the shape of a wedge. The pointing angle depends on the hardness of the metal being processed: the harder the metal, the greater the pointing angle should be. For steel processing, an angle of 60 degrees is recommended, for non-ferrous metals, an angle of 35 or 40. When cutting, hammers weighing 400 or 500 grams are used.

Locksmiths are used to cut metal hammers of two types: with round and square heads.

A special tool is used to cut grooves.

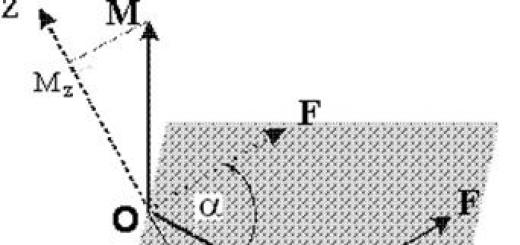

Next, the teacher talks about the preparation of the workplace, rules and techniques for cutting metal: « Preparation of the workplace consists in adjusting the height of the vise or installing a growth stand under the feet. The height of the vice according to the height of the worker is set as follows: bent at the elbow left hand it is necessary to put a vise on the jaws so that the ends of the straightened fingers touch the chin. The body of the body should be straight and half-turned (at an angle of 40 degrees) to the axis of the vise, the left leg is set half a step forward, and the angle formed by the lines of the axes of the feet should be approximately 75 degrees. When cutting metal, there must be a correct grip of the hammer and chisel tool

There are 3 types of blows with a hammer on a chisel. This is wrist, elbow and shoulder strikes. Wrist blow with a hammer is made only at the expense of the brush. It is used when removing burrs, chamfers, for cutting thin-sheet and soft metals, as well as at the end of cutting a workpiece. An elbow strike is used when cutting, when it is necessary to remove a layer of metal 2-3 mm thick. With an elbow strike, the arm is bent at the elbow, so it is stronger than the wrist strike. Shoulder impact is used when cutting metal with a thickness of 3-5 mm and processing large planes. The arm moves in the shoulder, resulting in a large swing and blow maximum strength. It must be accurate so that the center of the striker falls into the center of the workpiece chisels. Depending on the purpose, metal cutting can be clean and rough. When finishing cutting with a chisel, a layer of metal with a thickness of 0.5-1 mm is removed in one working move, with a rough cut 1-2 mm. Cutting in a vise according to the level of the jaws is the most common plumbing operation.

I will tell you the technique of cutting metal in a vise. The workpiece is firmly fixed in a vice, while the marking line should be at the level of the jaws or 1-2 mm lower so that filing can be performed after cutting. Then they take the working position, take the chisel with their left hand by the middle part at a distance of 20-25 mm from the edge of the shock part - the striker. The tool is installed so that its cutting edge is on the chip removal line (cut line), and the angle with respect to the machined surface is 30-35 degrees and approximately 45 to the vise jaws.

The hammer is held in the right hand (15-30 mm from the end of the handle) The blows should be slow and light at first, then stronger, uniform and accurate.

The cutting and cutting of metal is carried out on a plate or anvil. When cutting or cutting a workpiece of great thickness, first it is notched on one side, then it is turned over and the operation is repeated. The notched blank on both sides is carefully cut out on a slab or anvil.

“Guys, now let’s check how you understood the material you just studied”

The teacher takes a short break, asks students questions about the newly acquired knowledge, thereby updating knowledge.

1. What is felling?

2.What is a chisel?

3. At what level should the workpiece marking line, fixed in a vice, be located

a) Practical part

After the teacher has heard the answers to his questions, he tells the students that it is time to start practicing and distributes instruction and technological cards for making the key: “First of all, we need to choose a workpiece of the appropriate size.

Material - Steel. The workpiece thickness is 3 mm. The dimensions are 80 mm by 18. Then you need to do the filing operation, namely, cut the chamfers from the workpiece with a file, mark two centers for future holes. You will make holes using a drilling machine with a drill diameter of 7-8 mm. Then mark the workpiece as shown in the map and carry out cutting. After all, perform the sawing operation in order to remove burrs "

The teacher walks around the classroom, monitors safety and correct operations, helping students if possible, explains ambiguities. After the students have made their preparations, the teacher looks at how well the students completed the task.

«

Final part

The teacher sums up the scores. 5 minutes before the end of the lesson.

"Guys! Finish your work. Sign and turn in your work, and clean up your slaves. places. The attendants are sweeping the floor.

The teacher sums up the lesson. Gives all students marks, depending on the quality of their performance. At the same time explaining why he puts this or that assessment. For himself, the teacher draws conclusions about how the students learned the material.The bell rings, the teacher says next. topic and say goodbye to the students "

"General characteristics of metals" - Operating knowledge. Students' knowledge of chemistry. Chemistry. Story. Physics. The level of mastery of knowledge. Biology. Kaleidoscope. amazing world metals. Thinking mind.

"The structure of metal atoms" - The structure of metal atoms. filling with electrons. Write electronic formulas. Find matches. Sodium tetrahydroxozincate. Arrange the coefficients using the electronic balance method. Give two examples of reaction equations. Metals are elements in which the atoms are weakly interconnected. How will the corrosion process of iron change.

"The composition of the metal" - Now you will correctly call me. Contained in bone tissue vertebrates and shells of protozoa and molluscs. It is part of the teeth, bones, tissues and organs. The daily requirement for a person is 1.5 g or 0.5 l of milk, or 100 g of cheese. And capable, and skillful Younger soft brother Mel. And snow-white in crystal - Such honor and honor in palaces.

"Characteristics of metals" - Metallic luster. Many metals are widely distributed in nature. Iron. Metals comprise approximately 70% of all chemical elements. Contents of the work: The use of metals in human life. A large number of sodium and magnesium are found in sea water: - 1.05%, - 0.12%. Metals are one of the foundations of civilization on planet Earth.

““Metals” chemistry grade 10” - Sometimes small nuggets of copper fell into the hearth, which softened in the fire. An iron blade was found in Tutankhamun's tomb. All metals- solids except for mercury. R increases as the number of energy levels. The aluminothermic method is the reduction of metals with the help of aluminum.

"Lesson of metals" - Iron. biogenic metals. Precious metals and in the body - a jewel. Integrated lesson "Metals". Mercury. The use of metals. Copper. Still such people are cunning, unscrupulous and easily betray. Iron, steel, cast iron. The most common metal on Earth is aluminum (more than 8% of the earth's crust).

KSU "Agrotechnical College No. 10,

Akkol city, Akkol district"

Department of Education of Akmola region

Methodical development

industrial training lesson

Topic: "Metal cutting"

Developed by: master of industrial training

the first qualification category Lapshina E.V.

Topic: "Metal cutting" corresponds to the main professional program

The methodological development is compiled in accordance with work program for educational practice.

This methodical development presented as a detailed plan, abstract, supplied with the material necessary for the topic of the lesson.

The lesson meets the requirements of the methodology, consists of three main stages: introductory, current and final briefings. The lesson develops creative abilities and arouses interest in the profession being studied.

This topic is aimed at mastering the following competencies:

Perform typical plumbing operations used in the preparation of metal cutting.

Lesson topic: "Metal cutting"Lesson type: combined

The purpose of the lesson:

Educational: Learn to take the correct working position;

Educational : Learn to take the correct working position;

Select and prepare the tool for work;

Use tools and devices for cutting metal - hacksaws, hand scissors.

Observe safety precautions when performing metal cutting work.

Educational: the formation of the ability to self-expression;

Development of a sense of independence;

Development of self-control skills;

Rapid adaptation of the individual to real life conditions.

Objectives: to create conditions for the development of professional skills, methods, actions, creativity, logic, professional thinking based on the solution problem situations and tasks.

Lesson type: a lesson of exercises on the study of labor methods and operations.

Form of study: frontal.

Learning principles: accessibility, visibility, consistency and systematic, developing and educating the nature of learning.

Teaching methods: verbal - conversation, story, visual-demonstration, practical - performing simple complex work.

Equipment, materials and aids: hammer, metal shears, blanks - plates, square ruler, scriber, templates, metal shears, drawings, posters, construction and technological map.

During the classes

Organizational part (5 minutes.)

Induction training. (40 min.)

Repetition of the theoretical course of locksmithing on the topic "Scientific organization of work of a locksmith"

The message of the topic and purpose of the lesson: marking, bending, editing, cutting.

Learn how to prepare surfaces for marking, use marking tools: organize a workplace, rationally choose a marking tool.

Preparation of surfaces for marking and drawing lines (marks):

Rational choice of scriber

Scribe position

In order to properly manufacture the part, the contours of the future product are applied to the surface of the workpiece in the form of lines and points in compliance with the drawing dimensions. This plumbing operation is called markup.

The marking is carried out using a metal scale ruler, a bench square, a scriber, a marking compass and a center punch.

Review questions:

What tools are used to mark metal blanks?

What safety rules must be observed when marking?

What is the difference between marking metal blanks and marking blanks made of wood? What are their similarities?

What is the purpose of templates?

Name the profession of workers who make templates.

Name the types and causes of marriage when marking.

Explanation of the new material:

metal cutting is an operation for dividing metal blanks into parts.

Depending on the shape and size of the blanks, cutting is carried out with a hand saw, manual, power or lever scissors.

A hand saw for metal is used for cutting thick sheets of strip or profile metal, as well as for cutting blanks along the contour.

Hand saw device:

1 - shank with a handle; 2 - frame (machine); 3 - fixed head; 4 - hacksaw blade; 5 - collar nut; 6 - movable head; 7 - a device for extending the frame.

Working posture when cutting metal with a hacksaw

Working posture when cutting metal: a) set the height of the vise according to growth: right hand with a hacksaw, installed on the vise sponge (in its original position), bent at the elbow, should form a right angle (90 °) between the shoulder and the elbow part of the arm;b) stand in front of the vise freely and steadily, half-turned in relation to the jaws of the vise or to the axis of the object being cut;c) turn the body to the left of the vise at an angle of 45°;d) put the left leg forward a little, approximately along the line of the cut object and rest the body on it. Hacksaw movements must be made smoothly, without jerks; frequency of movements - 30-60 double moves (from oneself - towards oneself) per minute; at the same time, at least 2/3 of the length of the web should work.

With  silt shears:

silt shears:

Power shears are used when it is necessary to cut metal with a thickness of 1.5 - 2.5 mm.

Lever scissors

Lever shears can cut sheet metal up to 4 mm thick and soft metal up to 6 mm thick.

Hand scissorsHand scissors are used when cutting metal with a thickness of 0.5 - 1.5 mm. In this case, the scissor blades should be spread by about three quarters of their length, and the sheet of metal should be placed perpendicular to the plane of the cutting edges of the scissors. When squeezing the handles of the scissors, the blades should not be reduced to the end, as this leads to a break in the metal at the end of the cut.Fixing new material:1. Give a definition of the locksmith operation "metal cutting"?2. For what purposes is a hacksaw used for metal?3. List the types of scissors used when cutting metal?

Hand scissorsHand scissors are used when cutting metal with a thickness of 0.5 - 1.5 mm. In this case, the scissor blades should be spread by about three quarters of their length, and the sheet of metal should be placed perpendicular to the plane of the cutting edges of the scissors. When squeezing the handles of the scissors, the blades should not be reduced to the end, as this leads to a break in the metal at the end of the cut.Fixing new material:1. Give a definition of the locksmith operation "metal cutting"?2. For what purposes is a hacksaw used for metal?3. List the types of scissors used when cutting metal? current instruction. - (5 o'clock)

Independent work of students to consolidate and improve knowledge and skills, the formation of skills to perform the process of locksmith work.

Target rounds:

Individual demonstration of preparation, assembly, etc.

Checking the correctness of the task.

Bypassing workplaces in order to provide assistance to low-performing students.

Check the correct use of tools and equipment.

Checking the fulfillment of the time limit.

Checking the quality of the final result of work.

Final briefing. 15 minutes.