The value showing how many times the capacitance of the capacitor increases if the air gap between the plates is replaced with a gasket of the same thickness this material, is called the dielectric constant of this material. Dielectric constant (dielectric constant) for some materials is given in table. 26.

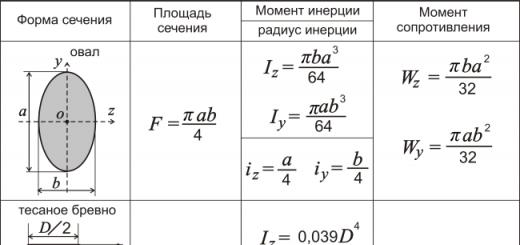

Table 26. Dielectric constant of some materials.

Material | The dielectric constant | Wood | The dielectric constant |

Spruce dry: along the fibers | |||

in the tangential direction | |||

in the radial direction | |||

Beech dry: along the grain | |||

in the tangential direction | |||

in the radial direction | |||

Data for wood show a noticeable difference between the dielectric constant along and across the fibers; at the same time, the permittivity across the fibers in the radial and tangential directions differs little. The dielectric constant in a high frequency field depends on the frequency of the current and the moisture content of the wood. With increasing current frequency, the dielectric constant of beech wood along the fibers at a moisture content of 0 to 12% decreases, which is especially noticeable for a moisture content of 12% (Fig. 45). With an increase in the moisture content of beech wood, the dielectric constant along the fibers increases, which is especially noticeable at a lower current frequency.

In a high frequency field, the wood heats up; the reason for the heating is the Joule heat loss inside the dielectric, which occurs under the influence of an alternating electromagnetic field. This heating consumes a part of the input energy, the value of which is characterized by the loss tangent.

The loss tangent depends on the direction of the field with respect to the fibers: it is approximately twice as large along the fibers as across the fibers. Across the fibers in the radial and tangential directions, the loss tangent differs little. The dielectric loss tangent, like the dielectric constant, depends on the frequency of the current and the moisture content of the wood. So, for absolutely dry beech wood, the loss tangent along the fibers first increases with increasing frequency, reaches a maximum at a frequency of 10 7 Hz, after which it begins to decrease again. At the same time, at a humidity of 12%, the loss tangent drops sharply with increasing frequency, reaches a minimum at a frequency of 105 Hz, and then increases just as sharply (Fig. 46).

Table 27. The maximum value of the loss tangent for dry wood.

With an increase in the moisture content of beech wood, the loss tangent along the fibers increases sharply at low (3 x 10 2 Hz) and high (10 9 Hz) frequencies and almost does not change at a frequency of 10 6 -10 7 Hz (see Fig. 46).

Through a comparative study of the dielectric properties of pine wood and cellulose, lignin and resin obtained from it, it was found that these properties are determined mainly by cellulose. Heating of wood in the field of high frequency currents is used in the processes of drying, impregnation and gluing.

When electricity appeared in our life, few people knew about its properties and parameters, and various materials were used as conductors, it was noticeable that with the same value of the voltage of the current source on the consumer there was different meaning voltage. It was clear that this was influenced by the type of material used as a conductor. When scientists took up the issue of studying this problem, they came to the conclusion that electrons are charge carriers in the material. And the ability to conduct electricity is isolated by the presence of free electrons in the material. It was found that in some materials these electrons a large number of while others don't have them at all. Thus, there are materials that, and some do not have this ability.

Based on the above, all materials were divided into three groups:

- conductors;

- semiconductors;

- dielectrics;

Each group found wide application in electrical engineering.

conductors

guides are materials that conduct electric current well, they are used for the manufacture of wires, cable products, contact groups, windings, tires, conductive cores and tracks. The vast majority of electrical devices and apparatus is made on the basis of conductive materials. Moreover, I will say that the entire electric power industry could not exist without these substances. The group of conductors includes all metals, some liquids and gases.

It is also worth mentioning that among the conductors there are super conductors, the resistance of which is almost zero, such materials are very rare and expensive. And conductors with high resistance - tungsten, molybdenum, nichrome, etc. Such materials are used to make resistors, heating elements, and lamp coils.

But the lion's share in the electrical field belongs to ordinary conductors: copper, silver, aluminum, steel, various alloys of these metals. These materials have found the widest and greatest application in electrical engineering, especially copper and aluminum, since they are relatively cheap, and their use as conductors of electric current is most appropriate. Even copper is limited in its use, it is used as winding wires, multi-core cables, and more critical devices, copper busbars are even rarer. But aluminum is considered the king among the conductors of electric current, even if it has a higher resistivity than copper, but this is offset by its very low cost and corrosion resistance. It is widely used in power supply, cable products, overhead lines, busbars, general wires, etc.

Semiconductors

Semiconductors, something between conductors and semiconductors. Their main feature is their dependence to conduct electric current from external conditions. The key condition is the presence of various impurities in the material, which just provide the ability to conduct electric current. Also, with a certain arrangement of two semiconductor materials. Based on these materials, at the moment, many semiconductor devices have been produced: LEDs, transistors,semistors, thyristors, stabistors, various microcircuits. There is a whole science devoted to semiconductors and devices based on them: electronic engineering. All computers mobile devices. What can I say, almost all of our equipment contains semiconductor elements.

Semiconductor materials include: silicon, germanium, graphite, gr aphene, indium, etc.

Dielectrics

Well, the last group of materials is dielectrics Substances that are not capable of conducting electricity. Such materials include: wood, paper, air, oil, ceramics, glass, plastics, polyethylene, polyvinyl chloride, rubber, etc. Dielectrics are widely used due to their properties. They are used as an insulating material. They protect the contact of two current-carrying parts, do not allow a person to directly touch these parts. The role of a dielectric in electrical engineering is no less important than the role of conductors, as they ensure the stable, safe operation of all electrical and electronic devices. All dielectrics have a limit to which they are not able to conduct electric current, it is called breakdown voltage. This is an indicator at which the dielectric begins to pass an electric current, while heat is released and the dielectric itself is destroyed. This breakdown voltage value is different for each dielectric material and is given in reference materials. The higher it is, the better, the dielectric is considered more reliable.

The parameter characterizing the ability to conduct electric current is resistivity R , unit [ Ohm ] and conductivity, reciprocal of resistance. The higher this parameter, the worse the material conducts electric current. For conductors, it is from a few tenths to hundreds of ohms. In dielectrics, the resistance reaches tens of millions of ohms.

All three types of materials are widely used in the electric power industry and electrical engineering. They are also closely related to each other.

Is wood a conductor or an insulator? and got the best answer

Answer from Lena Malikova[active]

dielectric. but only dry.

Answer from 2 answers[guru]

Hey! Here is a selection of topics with answers to your question: is wood a conductor or a dielectric??

Answer from Andrey Ryzhov[guru]

dielectric

Answer from www[newbie]

dielectric

Answer from white rabbit[guru]

Dry - dielectric.

Living - albeit bad, but a conductor, moreover - ionic (juices - electrolyte)

Answer from yyyyyyyyyyyyyyyyyyyyyyyyyyyying[guru]

how old is the tree

Answer from Alexei[expert]

Dry dielectric.

Answer from Eadovnik[guru]

The electrical conductivity of wood mainly depends on its moisture content, species, grain direction and temperature. Wood in a dry state does not conduct electricity, i.e., is a dielectric, which allows it to be used as an insulating material.

For example, paper impregnated with something is used in capacitors and transformers.

I myself often insert a fuse using a notebook sheet.

But a tree is never dry.

I still remember how I was shocked when I took a dry screwdriver with a wooden handle and reached into the switch.

And it is more correct to ask the resistance of the tree.

Lightning is more likely to strike trees with roots that penetrate deep into the soil. Why?

Trees with roots penetrating into deep aquifers of the soil are better connected to the earth and therefore, under the influence of electrified clouds, significant charges of electricity flowing from the earth accumulate on them, having a sign opposite to that of the cloud charge.

Due to its roots deep into the soil, the oak is well grounded, so it is more likely to be struck by lightning.

Electric current passes mainly between the bark and wood of the pine, that is, in those places where the most tree sap is concentrated, which conducts electricity well.

The trunk of a resinous tree, such as a pine tree, has a much greater resistance than the bark and subcortex. Therefore, in pine, the electric current of lightning passes mainly through the outer layers, without penetrating inside. If lightning strikes a deciduous tree, then the current flows inside it. The wood of these trees contains a lot of juice, which boils under the influence of an electric current. The resulting pairs break the tree.

The wooden pole provides a significant insulating distance in terms of surge voltages (lightning resistance), can extinguish the power arc of the ceiling and provides a high resistance to the earth fault circuit. These properties are used to reduce the number of lightning outages of overhead lines and ensure safety.

The impulse strength of the body of a wooden support is more than 200 kV/m. This property is extremely useful in areas with high thunderstorm activity. A lightning strike, even at a considerable distance from the line, can induce overvoltages on overhead lines with an amplitude of hundreds of kilovolts. The presence of wooden poles excludes overlapping insulation and disconnecting the line in such cases.

The high resistance of wooden poles ensures increased safety of the lines for people in the event of damage to the main insulation. The resistance of the support body is highly dependent on moisture. For example, the minimum resistance of wet pine is about 20 kOhm/m, while dry pine is on average 100 times greater.

The high resistance of wood and the high contact resistance when a person touches a support with damaged insulation limit the current through a person to non-life-threatening values (40–100 mA).

The ability to conduct electric current characterizes the electrical resistance of wood. AT general case The impedance of a wood sample placed between two electrodes is defined as the resultant of two resistances: volume and surface. The volume resistance numerically characterizes the obstacle to the passage of current through the thickness of the sample, and the surface resistance determines the obstacle to the passage of current along the surface of the sample. Indicators of electrical resistance are specific volume and surface resistance. The first of these indicators has the dimension of ohm per centimeter (ohm x cm) and is numerically equal to the resistance when current passes through two opposite faces of a 1X1X1 cm cube made of a given material (wood). The second indicator is measured in ohms and is numerically equal to the resistance of a square of any size on the surface of a wood sample when current is applied to the electrodes that limit two opposite sides of this square. The electrical conductivity depends on the type of wood and the direction of current flow. As an illustration of the order of magnitude of volume and surface resistance in table. some data is given.

comparative data on the specific volume and surface resistance of wood

To characterize the electrical conductivity highest value has a specific volume resistivity. The resistance is highly dependent on the moisture content of the wood. As the moisture content of the wood increases, the resistance decreases. A particularly sharp decrease in resistance is observed with an increase in the content of bound moisture from an absolutely dry state to the limit of hygroscopicity. In this case, the specific volume resistance decreases millions of times. A further increase in humidity causes a drop in resistance only tenfold. This is illustrated by the data in Table.

specific volume resistance of wood in a completely dry state

| Breed | Specific volume resistance, ohm x cm | |

| across the fibers | along the fibers | |

| Pine | 2.3 x 10 15 | 1.8 x 10 15 |

| Spruce | 7.6 x 10 16 | 3.8 x 10 16 |

| Ash | 3.3 x 10 16 | 3.8 x 10 15 |

| Hornbeam | 8.0 x 10 16 | 1.3 x 10 15 |

| Maple | 6.6 x 10 17 | 3.3 x 10 17 |

| Birch | 5.1 x 10 16 | 2.3 x 10 16 |

| Alder | 1.0 x 10 17 | 9.6 x 10 15 |

| Linden | 1.5 x 10 16 | 6.4 x 10 15 |

| Aspen | 1.7 x 10 16 | 8.0 x 10 15 |

influence of humidity on the electrical resistance of wood

The surface resistance of wood also decreases significantly with increasing humidity. An increase in temperature leads to a decrease in the volumetric resistance of wood. Thus, the resistance of false wood wood with an increase in temperature from 22-23 ° to 44-45 ° C (approximately twice) drops by 2.5 times, and beech wood with an increase in temperature from 20-21 ° to 50 ° C - 3 times. At negative temperatures, the volume resistance of wood increases. The specific volume resistance along the fibers of birch samples with a moisture content of 76% at a temperature of 0 ° C was 1.2 x 10 7 ohm cm, and when cooled to a temperature of -24 ° C, it turned out to be 1.02 x 10 8 ohm cm. Impregnation of wood with mineral antiseptics (for example, zinc chloride) reduces the resistivity, while impregnation with creosote has little effect on electrical conductivity. The electrical conductivity of wood is of practical importance when it is used for communication poles, masts of high-voltage transmission lines, handles of power tools, etc. In addition, the electrical moisture meters are based on the dependence of electrical conductivity on wood moisture content.

electric strength of wood

Electrical strength is important when evaluating wood as an electrically insulating material and is characterized by a breakdown voltage in volts per 1 cm of material thickness. The electrical strength of wood is low and depends on the species, humidity, temperature and direction. With increasing humidity and temperature, it decreases; along the fibers it is much lower than across. Data on the electrical strength of wood along and across the fibers are given in table.

electrical strength of wood along and across the fibers

With a moisture content of pine wood of 10%, the following electrical strength was obtained in kilovolts per 1 cm of thickness: along the fibers 16.8; in the radial direction 59.1; in the tangential direction 77.3 (the determination was made on samples 3 mm thick). As you can see, the electrical strength of wood along the fibers is about 3.5 times less than across the fibers; in the radial direction, the strength is less than in the tangential direction, since the core rays reduce the breakdown voltage. Increasing the humidity from 8 to 15% (by a factor of two) reduces the dielectric strength across the fibers by about 3 times (average for beech, birch and alder).

The electrical strength (in kilovolts per 1 cm of thickness) of other materials is as follows: mica 1500, glass 300, bakelite 200, paraffin 150, transformer oil 100, porcelain 100. In order to increase the electrical strength of wood and reduce electrical conductivity when used in the electrical industry as an insulator it is impregnated with drying oil, transformer oil, paraffin, artificial resins; The effectiveness of such impregnation is evident from the following data on birch wood: impregnation with drying oil increases the breakdown voltage along the fibers by 30%, with transformer oil - by 80%, with paraffin - almost twice as compared with the breakdown voltage for air-dry unimpregnated wood.

dielectric properties of wood

The value showing how many times the capacitance of the capacitor increases if the air gap between the plates is replaced by a gasket of the same thickness from a given material is called the dielectric constant of this material. Dielectric constant (dielectric constant) for some materials is given in table.

permittivity of some materials

| Material | Wood | The dielectric constant | |

| Air | 1,00 | Spruce dry: along the fibers | 3,06 |

| in the tangential direction | 1,98 | ||

| Paraffin | 2,00 | ||

| in the radial direction | 1,91 | ||

| Porcelain | 5,73 | ||

| Mica | 7,1-7,7 | Beech dry: along the grain | 3,18 |

| in the tangential direction | 2,20 | ||

| Marble | 8,34 | ||

| in the radial direction | 2,40 | ||

| Water | 80,1 |

Data for wood show a noticeable difference between the dielectric constant along and across the fibers; at the same time, the permittivity across the fibers in the radial and tangential directions differs little. The dielectric constant in a high frequency field depends on the frequency of the current and the moisture content of the wood. With increasing current frequency, the dielectric constant of beech wood along the fibers at a moisture content of 0 to 12% decreases, which is especially noticeable for a moisture content of 12%. With an increase in the moisture content of beech wood, the dielectric constant along the fibers increases, which is especially noticeable at a lower current frequency.

In a high frequency field, the wood heats up; the reason for the heating is the Joule heat loss inside the dielectric, which occurs under the influence of an alternating electromagnetic field. This heating consumes a part of the input energy, the value of which is characterized by the loss tangent.

The loss tangent depends on the direction of the field with respect to the fibers: it is approximately twice as large along the fibers as across the fibers. Across the fibers in the radial and tangential directions, the loss tangent differs little. The dielectric loss tangent, like the dielectric constant, depends on the frequency of the current and the moisture content of the wood. So, for absolutely dry beech wood, the loss tangent along the fibers first increases with increasing frequency, reaches a maximum at a frequency of 10 7 Hz, after which it begins to decrease again. At the same time, at a humidity of 12%, the loss tangent drops sharply with increasing frequency, reaches a minimum at a frequency of 105 Hz, and then increases just as sharply.

maximum loss tangent for dry wood

With an increase in the moisture content of beech wood, the loss tangent along the fibers increases sharply at low (3 x 10 2 Hz) and high (10 9 Hz) frequencies and almost does not change at a frequency of 10 6 -10 7 Hz.

Through a comparative study of the dielectric properties of pine wood and cellulose, lignin and resin obtained from it, it was found that these properties are determined mainly by cellulose. Heating of wood in the field of high frequency currents is used in the processes of drying, impregnation and gluing.

piezoelectric properties of wood

On the surface of some dielectrics under the action of mechanical stresses appear electric charges. This phenomenon associated with the polarization of the dielectric is called the direct piezoelectric effect. Piezoelectric properties were first discovered in crystals of quartz, tourmaline, Rochelle salt, etc. These materials also have an inverse piezoelectric effect, which consists in the fact that their dimensions change under the action of electric field. Plates made of these crystals are widely used as emitters and receivers in ultrasonic technology.

These phenomena are found not only in single crystals, but also in a number of other anisotropic solid materials called piezoelectric textures. Piezoelectric properties have also been found in wood. It was found that the main carrier of piezoelectric properties in wood is its oriented component - cellulose. The intensity of polarization of wood is proportional to the magnitude of mechanical stresses from the applied external forces; the proportionality factor is called the piezoelectric modulus. The quantitative study of the piezoelectric effect, therefore, is reduced to the determination of the values of the piezoelectric moduli. Due to the anisotropy of the mechanical and piezoelectric properties of wood, these indicators depend on the direction of mechanical forces and the polarization vector.

The greatest piezoelectric effect is observed under compressive and tensile loads at an angle of 45° to the fibers. Mechanical stresses directed strictly along or across the fibers do not cause a piezoelectric effect in wood. In table. the values of piezoelectric modules for some rocks are given. The maximum piezoelectric effect is observed in dry wood, with increasing humidity it decreases, and then completely disappears. So, already at a humidity of 6-8%, the magnitude of the piezoelectric effect is very small. With an increase in temperature to 100 ° C, the value of the piezoelectric modulus increases. With a small elastic deformation (high modulus of elasticity) of wood, the piezoelectric modulus decreases. The piezoelectric modulus also depends on a number of other factors; but greatest influence its value is influenced by the orientation of the cellulose component of the wood.

piezoelectric wood modules

The open phenomenon allows a deeper study of the fine structure of wood. Indicators of the piezoelectric effect can serve as quantitative characteristics cellulose orientations and are therefore very important for studying the anisotropy of natural wood and new wood materials with properties specified in certain directions.

Wood (wood) is an insulator: its electrical conductivity is very low at room temperature, especially if the wood is dry. When heated, the wood chars. Charcoal (graphite with a partially disordered lattice) is a conductor of electric current: far from the best, but a conductor. Our experiment is based on the described principle. We take a 220 V light bulb, turn on two electrodes (nails, steel wire, etc.) in series with it, which are located in parallel at a distance of about 1-2 cm. Plug it all into a socket. The lamp, of course, does not burn, since the circuit is open: the electrodes are separated by a centimeter of air. Place a few matches on top of the electrodes. The matches will connect the electrodes, but the wood is an insulator, so the lamp will not burn. We direct the flame of a gas burner at the lamp. The wood will catch fire and char, the coal will connect the two electrodes, and since coal is a conductor, the circuit will close and the lamp will light up. The gas burner will light the lamp.

It sounds simple, but in practice it's a little more complicated. Several nuances.

1. The tree must be completely charred.

The process of wood charring differs, for example, from the decomposition of calcium carbonate (into calcium oxide and carbon dioxide) by the fact that wood thermolysis goes through many stages. We are not satisfied with the products of the intermediate stages: the carbonization of the wood must be complete. A sign of this: the tree stops burning - the flame disappears, the tree only smolders (i.e. volatile combustible thermolysis products are no longer formed).

2. Matches may bend in the flame during heating, resulting in loss of contact with the electrodes. Sometimes further heating helps: the matches bend until they touch the electrode again. (It is possible that the heating process itself is also important to improve contact). It is necessary not to overdo it and not burn the coal completely.

In the process of charring, matches often fall, therefore, before the experiment, they must be placed on the electrodes so that neither end outweighs the other (loops on the electrodes are useful - see below).

3. In some cases, a charred match can be corrected and pressed against the electrodes with an ordinary match - to restore contact. It is advisable to make electrodes with "loops" at the ends, and insert matches into the loops: this improves contact.

4. During the experiment, the electrodes are covered with scale and soot. Between experiments, it is desirable to clean them off to improve contact (apparently, this is not necessary).

5. During the experiment, the bare electrodes are energized at 220 V. The experimenter has to manipulate these electrodes many times: place matches on them, correct charred matches, demonstrate with a multimeter that the electrodes are energized, etc. Not every experience goes well, so routine procedures need to be done again and again. As a result, it is easy to forget that the electrodes are live and accidentally touch them.

In the course of the experiments, I touched the energized electrodes twice. Once - with sweaty hands, standing with bare feet on linoleum. The palm twitched, I dropped the pliers and uttered a couple of "cultural" words. The second time I didn't feel anything at all. - Got off easy.

But if a person simultaneously touches bare wires and grounded objects (water pipe, central heating battery, etc.), the result can be fatal. It is especially bad if the hands are wet, because. the electrical resistance of the human body is concentrated mainly in the skin.

So, there is a 220 V lamp in the circuit, two electrodes are connected in series with it. The role of electrodes in various experiments was played by nails, large paper clips and steel wire. The electrodes are arranged in parallel and at the same level (so that matches or pieces of wood can be placed on top of them). To prove that the circuit is energized, I connect the electrodes with a screwdriver. The lamp lights up brightly. I remove the screwdriver - the lamp goes out.

I put several matches on the electrodes so that they connect them. The lamp does not burn because wood is an insulator. I direct the flame of the burner at the matches, charring them evenly along the entire length. When red coals remain from the matches, the circuit closes, the lamp lights up. At the point of contact of the match with the electrodes, a bluish electric arc often flashes, the match itself in some places remains red-hot. This is accompanied by a characteristic crackle. After a few seconds or tens of seconds, the match burns out, the contact is lost, the lamp goes out. But often the contact is restored in new places, the arc flashes again, sparks and crackles appear. The lamp lights up again: sometimes brightly and almost evenly, sometimes dimly and with flashes (depending on how good the contact is). If necessary, charred matches are corrected and pressed against the electrodes with an unburned match. If this does not work, they direct the flame of the burner to the charred matches.

If desired, 3-4 matches or 1-2 can be used in the experiment.