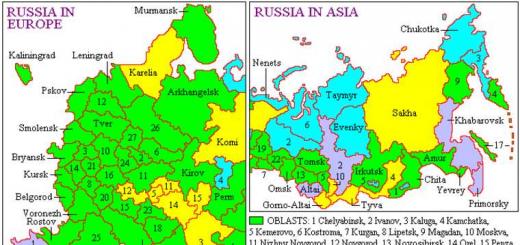

Photonic crystals can be divided into three main classes according to the nature of the change in refractive index:

1. One-dimensional, in which the refractive index periodically changes in one spatial direction as shown in Figure 2. In this figure, the symbol L indicates the period of change in the refractive index, and and are the refractive indices of two materials (but in the general case, any number of materials may be present). Such photonic crystals consist of layers of different materials parallel to each other with different refractive indices and can exhibit their properties in one spatial direction, perpendicular to the layers.

Figure 1 - Schematic representation of a one-dimensional photonic crystal

2. Two-dimensional, in which the refractive index varies periodically in two spatial directions as shown in Figure 2. In this figure, the photonic crystal is created by rectangular regions with a refractive index, which are located in a medium with a refractive index. In this case, regions with a refractive index are ordered in a two-dimensional cubic lattice. Such photonic crystals can exhibit their properties in two spatial directions, and the shape of the regions with the refractive index is not limited to rectangles, as in the figure, but can be any (circles, ellipses, arbitrary, etc.). The crystal lattice in which these areas are ordered can also be different, and not just cubic, as in the above figure.

Figure - 2 Schematic representation of a two-dimensional photonic crystal

3. Three-dimensional, in which the refractive index periodically changes in three spatial directions. Such photonic crystals can exhibit their properties in three spatial directions, and they can be represented as an array of volumetric regions (spheres, cubes, etc.) ordered in a three-dimensional crystal lattice.

Like electrical media, depending on the width of the forbidden and allowed zones, photonic crystals can be divided into conductors - capable of conducting light over long distances with low losses, dielectrics - almost ideal mirrors, semiconductors - substances capable, for example, of selectively reflecting photons of a certain wavelength and superconductors, in which, thanks to collective phenomena, photons are able to propagate over almost unlimited distances.

There are also resonant and non-resonant photonic crystals. Resonant photonic crystals differ from non-resonant ones in that they use materials whose dielectric constant (or refractive index) as a function of frequency has a pole at some resonant frequency.

Any inhomogeneity in a photonic crystal is called a photonic crystal defect. The electromagnetic field is often concentrated in such areas, which is used in microcavities and waveguides built on the basis of photonic crystals.

Like electrical media, depending on the width of the forbidden and allowed zones, photonic crystals can be divided into conductors - capable of conducting light over long distances with low losses, dielectrics - almost ideal mirrors, semiconductors - substances capable, for example, of selectively reflecting photons of a certain wavelength and superconductors, in which, thanks to collective phenomena, photons are able to propagate over almost unlimited distances. There are also resonant and non-resonant photonic crystals. Resonant photonic crystals differ from non-resonant ones in that they use materials whose dielectric constant (or refractive index) as a function of frequency has a pole at some resonant frequency.

Any inhomogeneity in a photonic crystal is called a photonic crystal defect. The electromagnetic field is often concentrated in such areas, which is used in microcavities and waveguides built on the basis of photonic crystals. There are a number of analogies when describing the propagation of electromagnetic waves in photonic crystals and the electronic properties of crystals. Let's list some of them.

1. The state of the electron inside the crystal (the law of motion) is given by solving the Schrldinger equation; the propagation of light in a photonic crystal obeys the wave equation, which is a consequence of Maxwell’s equations:

- 2. The state of the electron is described by the scalar wave function w(r,t), the state of the electromagnetic wave is described by vector fields - the strength of the magnetic or electrical components, H (r,t) or E(r,t).

- 3. The electron wave function w(r,t) can be expanded into a series of eigenstates wE(r), each of which has its own energy E. The electromagnetic field strength H(r,t) can be represented by a superposition of monochromatic components (modes) electromagnetic field Hsh(r), each of which corresponds to its own value - the mode frequency u:

4. Atomic potential U(r) and dielectric constant e(r), appearing in the Schrldinger and Maxwell equations, are periodic functions with periods equal to any vectors R of the crystal lattice and photonic crystal, respectively:

U(r) = U(r + R), (3)

5. For the electron wave function and the electromagnetic field strength, Bloch’s theorem is satisfied with periodic functions u k and u k.

- 6. Possible values of wave vectors k fill the Brillouin zone of the crystal lattice or unit cell of a photonic crystal, defined in the space of inverse vectors.

- 7. The electron energy E, which is the eigenvalue of the Schrldinger equation, and the eigenvalue of the wave equation (consequences of Maxwell’s equations) - the mode frequency u - are related to the values of the wave vectors k of the Bloch functions (4) by the dispersion law E(k) and u(k).

- 8. An impurity atom that violates the translational symmetry of the atomic potential is a crystal defect and can create an impurity electronic state localized in the vicinity of the defect. Changes in the dielectric constant in a certain region of the photonic crystal break the translational symmetry e(r) and lead to the appearance of a permitted mode inside the photonic band gap, localized in its spatial vicinity.

Classification of methods for manufacturing photonic crystals. Photonic crystals are very rare in nature. They are distinguished by a special rainbow play of light - an optical phenomenon called iridescence (translated from Greek - rainbow). Such minerals include calcite, labradorite and opal SiO 2 ×n∙H 2 O with various inclusions. The most famous among them is opal - a semi-precious mineral, which is a colloidal crystal consisting of monodisperse spherical globules of silicon oxide. The play of light in the latter gives rise to the term opalescence, which denotes a special type of radiation scattering characteristic only of this crystal.

The main methods for manufacturing photonic crystals include methods that can be divided into three groups:

1. Methods using spontaneous formation of photonic crystals. This group of methods uses colloidal particles, such as monodisperse silicone or polystyrene particles, as well as other materials. Such particles, being in liquid vapor during evaporation, settle in a certain volume. As the particles deposit on each other, they form a three-dimensional photonic crystal, and are ordered predominantly into face-centered or hexagonal crystal lattices. The cellular method is also possible, which involves filtering a liquid containing particles through small spores. Although the honeycomb method allows the formation of a crystal at a relatively high speed, determined by the speed of liquid flow through the pores, however, defects form in such crystals when drying. There are other methods that use the spontaneous formation of photonic crystals, but each method has its own advantages and disadvantages. Most often, these methods are used to deposit spherical colloidal silicone particles, however, the resulting refractive index contrast is relatively small.

2. Methods using etching of objects. This group of methods uses a photoresist mask formed on the surface of the semiconductor, which sets the geometry of the etching area. Using such a mask, a simple photonic crystal is formed by etching the surface of a semiconductor not covered with photoresist. The disadvantage of this method is the need to use photolithography with high resolution at the level of tens and hundreds of nanometers. Beams of focused ions, such as Ga, are also used to produce photonic crystals by etching. Such ion beams make it possible to remove part of the material without the use of photolithography and additional etching. To increase the etching speed and improve its quality, as well as to deposit materials inside the etched areas, additional treatment with the necessary gases is used.

3. Holographic methods. Such methods are based on the application of holographic principles. Using holography, periodic changes in the refractive index in spatial directions are formed. To do this, the interference of two or more coherent waves is used, which creates a periodic distribution of the intensity of electromagnetic radiation. One-dimensional photonic crystals are created by the interference of two waves. Two-dimensional and three-dimensional photonic crystals are created by the interference of three or more waves.

The choice of a specific method for manufacturing photonic crystals is largely determined by the size of the structure that needs to be manufactured - one-dimensional, two-dimensional or three-dimensional.

One-dimensional periodic structures. The simplest and most common way to obtain one-dimensional periodic structures is vacuum layer-by-layer deposition of polycrystalline films from dielectric or semiconductor materials. This method has become widespread due to the use of periodic structures in the production of laser mirrors and interference filters. In such structures, when using materials with refractive indices that differ by approximately 2 times (for example, ZnSe and Na 3 AlF 6), it is possible to create spectral reflection bands (photonic band gaps) up to 300 nm wide, covering almost the entire visible region of the spectrum.

Advances in the synthesis of semiconductor heterostructures in recent decades have made it possible to create completely single-crystalline structures with a periodic change in the refractive index along the growth direction using molecular beam epitaxy or organometallic vapor deposition techniques. Currently, such structures are part of semiconductor lasers with vertical cavities. The maximum currently achievable ratio of refractive indices of materials apparently corresponds to the GaAs/Al 2 O 3 pair and is about 2. It should be noted the high perfection of the crystal structure of such mirrors and the accuracy of the formation of layer thicknesses at the level of one lattice period (about 0.5 nm).

Recently, the possibility of creating periodic one-dimensional semiconductor structures using a photolithographic mask and selective etching has been demonstrated. When etching silicon, it is possible to create structures with a period of the order of 1 micron or more, while the ratio of the refractive indices of silicon and air in the near-infrared region is 3.4 - an unprecedentedly large value unattainable by other synthesis methods. An example of a similar structure obtained at the Physico-Technical Institute named after. A.F. Ioffe RAS (St. Petersburg), shown in Fig. 3.96.

Rice. 3.96. Periodic structure of silicon - air, obtained by anisotropic etching using a photolithographic mask (structure period 8 μm)

Two-dimensional periodic structures. Two-dimensional periodic structures can be fabricated using selective etching of semiconductors, metals, and dielectrics. Selective etching technology has been developed for silicon and aluminum due to the widespread use of these materials in microelectronics. Porous silicon, for example, is considered a promising optical material that will allow the creation of highly integrated optoelectronic systems. The combination of advanced silicon technologies with quantum-size effects and the principles of the formation of photonic band gaps has led to the development of a new direction - silicon photonics.

The use of submicron lithography to form masks makes it possible to create silicon structures with a period of 300 nm or less. Due to their strong absorption of visible light, silicon photonic crystals can only be used in the near and mid-infrared regions of the spectrum. The combination of etching and oxidation, in principle, makes it possible to move to periodic silicon oxide-air structures, but at the same time the low refractive index ratio (1.45) does not allow the formation of a full band gap in two dimensions.

Two-dimensional periodic structures from semiconductor compounds A 3 B 5, also obtained by selective etching using lithographic masks or templates, seem promising. A 3 B 5 compounds are the main materials of modern optoelectronics. InP and GaAs compounds have larger band gaps than silicon and refractive index values that are as high as silicon, equal to 3.55 and 3.6, respectively.

Periodic structures based on aluminum oxide seem very interesting (Fig. 3.97a). They are obtained by electrochemical etching of aluminum metal, on the surface of which a mask is formed using lithography. Using electron lithographic templates, perfect two-dimensional periodic structures resembling a honeycomb with a pore diameter of less than 100 nm were obtained. It should be noted that selective etching of aluminum under a certain combination of etching conditions makes it possible to obtain regular structures even without the use of any masks or templates (Fig. 3.97b). The pore diameter can be only a few nanometers, which is unattainable with modern lithographic methods. The periodicity of pores is associated with the self-regulation of the process of aluminum oxidation during an electrochemical reaction. The initial conductive material (aluminum) is oxidized to Al 2 O 3 during the reaction. The aluminum oxide film, which is a dielectric, reduces the current and slows down the reaction. The combination of these processes allows a self-sustaining reaction regime to be achieved, in which continuous etching is made possible by the passage of current through the pores, and the reaction product forms a regular honeycomb structure. Some irregularity of the pores (Fig. 3.97b) is due to the granular structure of the original polycrystalline aluminum film.

Rice. 3.97. Two-dimensional photonic crystal from Al 2 O 3: a) made using a lithographic mask; b) manufactured using self-regulation of the oxidation process

A study of the optical properties of nanoporous aluminum oxide showed an unusually high transparency of this material along the direction of the pores. The absence of Fresnel reflection, which inevitably exists at the interface between two continuous media, leads to transmittance values reaching 98%. In directions perpendicular to the pores, high reflection is observed with a reflection coefficient depending on the angle of incidence.

The relatively low values of the dielectric constant of aluminum oxide, in contrast to silicon, gallium arsenide and indium phosphide, do not allow the formation of a full band gap in two dimensions. However, despite this, the optical properties of porous aluminum oxide turn out to be quite interesting. For example, it has pronounced anisotropic light scattering, as well as birefringence, which makes it possible to use it to rotate the plane of polarization. Using various chemical methods, it is possible to fill pores with various oxides, as well as optically active materials, for example, nonlinear optical media, organic and inorganic phosphors, and electroluminescent compounds.

Three-dimensional periodic structures. Three-dimensional periodic structures are objects that have the greatest technological difficulties for experimental implementation. Historically, the first method of creating a three-dimensional photonic crystal is considered to be a method based on mechanical drilling of cylindrical holes in the bulk of the material, proposed by E. Yablonovich. Manufacturing such a three-dimensional periodic structure is a rather labor-intensive task, so many researchers have attempted to create a photonic crystal using other methods. Thus, in the Lin–Fleming method, a layer of silicon dioxide is applied to a silicon substrate, in which parallel strips are then formed and filled with polycrystalline silicon. Next, the process of applying silicon dioxide is repeated, but the stripes are formed in a perpendicular direction. After creating the required number of layers, the silicon oxide is removed by etching. As a result, a “woodpile” of polysilicon rods is formed (Fig. 3.98). It should be noted that the use of modern methods of submicron electron lithography and anisotropic ion etching makes it possible to obtain photonic crystals with a thickness of less than 10 structural cells.

Rice. 3.98. Three-dimensional photonic structure made of polysilicon rods

Methods for creating photonic crystals for the visible range, based on the use of self-organizing structures, have become widespread. The very idea of “assembling” photonic crystals from globules (balls) was borrowed from nature. It is known, for example, that natural opals have the properties of photonic crystals. The natural mineral opal in chemical composition is a silicon dioxide hydrogel SiO 2 × H 2 O with variable water content: SiO 2 – 65 – 90 wt. %; H 2 O – 4.5–20%; Al 2 O 3 – up to 9%; Fe 2 O 3 – up to 3%; TiO 2 – up to 5%. Using electron microscopy methods, it was established that natural opals are formed by densely packed spherical α-SiO 2 particles of uniform size with a diameter of 150 – 450 nm. Each particle consists of smaller globular formations with a diameter of 5–50 nm. The voids in the globule packing are filled with amorphous silicon oxide. The intensity of diffracted light is influenced by two factors: the first is the “ideality” of the densest packing of globules, the second is the difference in the refractive indices of amorphous and crystalline SiO 2 oxide. Noble black opals have the best play of light (for them the difference in refractive index values is ~0.02).

It is possible to create globular photonic crystals from colloidal particles in various ways: natural sedimentation (sedimentation of a dispersed phase in a liquid or gas under the influence of a gravitational field or centrifugal forces), centrifugation, filtration using membranes, electrophoresis, etc. Spherical particles act as colloidal particles polystyrene, polymethyl methacrylate, particles of silicon dioxide α-SiO 2.

The natural deposition method is a very slow process, requiring several weeks or even months. Centrifugation greatly accelerates the process of formation of colloidal crystals, but the materials obtained in this way are less ordered, since at a high sedimentation rate, separation of particles by size does not have time to occur. To speed up the sedimentation process, electrophoresis is used: they create a vertical electric field that “changes” the gravity of the particles depending on their size. Methods based on the use of capillary forces are also used. The basic idea is that under the action of capillary forces, crystallization occurs at the meniscus interface between the vertical substrate and the suspension, and as the solvent evaporates, a fine ordered structure is formed. Additionally, a vertical temperature gradient is used, which makes it possible to better optimize the speed of the process and the quality of the created crystal due to convection flows. In general, the choice of technique is determined by the requirements for the quality of the resulting crystals and the time required for their production.

The technological process of growing synthetic opals using natural sedimentation can be divided into several stages. Initially, a monodisperse (~ 5% deviation in diameter) suspension of spherical globules of silicon oxide is prepared. The average particle diameter can vary over a wide range: from 200 to 1000 nm. The most well-known method for producing monodisperse colloidal microparticles of silicon dioxide is based on the hydrolysis of tetraethoxysilane Si(C 2 H 4 OH) 4 in an aqueous alcoholic medium in the presence of ammonium hydroxide as a catalyst. This method can produce particles with a smooth surface of an almost ideal spherical shape with a high degree of monodispersity (less than 3% deviation in diameter), as well as create particles with sizes less than 200 nm with a narrow size distribution. The internal structure of such particles is fractal: the particles consist of densely packed spheres of a smaller size (diameter of several tens of nanometers), and each such sphere is formed by polyhydroxy silicon complexes consisting of 10–100 atoms.

The next stage is the deposition of particles (Fig. 3.99). It can last for several months. Upon completion of the deposition stage, a close-packed periodic structure is formed. Next, the deposit is dried and annealed at a temperature of about 600 ºС. During the annealing process, softening and deformation of the spheres occurs at the points of contact. As a result, the porosity of synthetic opals is less than that for an ideal dense spherical packing. Perpendicular to the direction of the growth axis of the photonic crystal, the globules form highly ordered hexagonal close-packed layers.

Rice. 3.99. Stages of growing synthetic opals: a) deposition of particles;

b) drying the sediment; c) sample annealing

In Fig. Figure 3.100a shows a micrograph of synthetic opal obtained by scanning electron microscopy. The dimensions of the spheres are 855 nm. The presence of open porosity in synthetic opals allows the voids to be filled with various materials. Opal matrices are three-dimensional sublattices of interconnected nano-sized pores. The pore sizes are on the order of hundreds of nanometers; the sizes of the channels connecting the pores reach tens of nanometers. In this way, nanocomposites based on photonic crystals are obtained. The main requirement put forward when creating high-quality nanocomposites is the complete filling of the nanoporous space. Filling is carried out using various methods: injection from a solution into the melt; impregnation with concentrated solutions followed by evaporation of the solvent; electrochemical methods, chemical vapor deposition, etc.

Rice. 3.100. Microphotographs of photonic crystals: a) from synthetic opal;

b) from polystyrene microspheres

When selective etching of silicon oxide from such composites, spatially ordered nanostructures with high porosity (more than 74% of the volume), called reverse or inverted opals, are formed. This method of producing photonic crystals is called the template method. Not only silicon oxide particles, but also, for example, polymer particles can act as ordered monodisperse colloidal particles forming a photonic crystal. An example of a photonic crystal based on polystyrene microspheres is shown in Fig. 3.100b

2

Introduction Since ancient times, a person who found a photonic crystal was fascinated by its special rainbow play of light. It was found that the iridescent iridescence of the scales and feathers of various animals and insects is due to the existence of superstructures on them, which are called photonic crystals for their reflective properties. Photonic crystals are found in nature in/on: minerals (calcite, labradorite, opal); on the wings of butterflies; beetle shells; the eyes of some insects; algae; scales of fish; peacock feathers 3

Photonic crystals This is a material whose structure is characterized by a periodic change in the refractive index in spatial directions. Photonic crystal based on aluminum oxide. M. DEUBEL, G.V. FREYMANN, MARTIN WEGENER, SURESH PEREIRA, KURT BUSCH AND COSTAS M. SOUKOULIS “Direct laser writing of three-dimensional photonic-crystal templates for telecommunications” // Nature materials Vol. 3, P

A little history... 1887 Rayleigh first investigated the propagation of electromagnetic waves in periodic structures, which is analogous to a one-dimensional photonic crystal Photonic Crystals - the term was introduced in the late 1980s. to denote the optical analogue of semiconductors. These are artificial crystals made from a translucent dielectric in which air “holes” are created in an orderly manner. 5

Photonic crystals are the future of world energy High-temperature photonic crystals can act not only as an energy source, but also as extremely high-quality detectors (energy, chemical) and sensors. The photonic crystals created by Massachusetts scientists are based on tungsten and tantalum. This compound is capable of performing satisfactorily at very high temperatures. Up to ˚С. In order for a photonic crystal to begin converting one type of energy into another convenient for use, any source (thermal, radio emission, hard radiation, sunlight, etc.) is suitable. 6

7

The law of dispersion of electromagnetic waves in a photonic crystal (diagram of extended zones). The right side shows for a given direction in the crystal the relationship between the frequency? and the values of ReQ (solid curves) and ImQ (dashed curve in the omega stop zone -

Photonic band gap theory It wasn't until 1987, when Eli Yablonovitch, a Bell Communications Research fellow (now a professor at UCLA), introduced the concept of an electromagnetic band gap. To broaden your horizons: Lecture by Eli Yablonovitch yablonovitch-uc-berkeley/view Lecture by John Pendry john-pendry-imperial-college/view 9

In nature, photonic crystals are also found: on the wings of African swallowtail butterflies, the mother-of-pearl coating of shellfish shells such as abalones, the antennae of a sea mouse and the bristles of a polychaete worm. Photo of a bracelet with opal. Opal is a natural photonic crystal. It is called the “stone of false hopes” 10

11

There is no heating and photochemical destruction of pigment material" title="Advantages of filters based on PC over the absorption mechanism (absorbing mechanism) for living organisms: Interference coloring does not require absorption and dissipation of light energy, => no heating and photochemical destruction of pigment material" class="link_thumb"> 12 !} Advantages of PC-based filters over the absorption mechanism (absorbing mechanism) for living organisms: Interference coloring does not require absorption and dissipation of light energy, => there is no heating and photochemical destruction of the pigment coating. Butterflies living in hot climates have iridescent wing patterns, and the structure of the photonic crystal on the surface appears to reduce the absorption of light and, therefore, the heating of the wings. The sea mouse has been using photonic crystals in practice for a long time. 12 no heating and photochemical destruction of the pigment coating. No heating and photochemical destruction of the pigment coating. Butterflies living in hot climates have an iridescent wing pattern, and the structure of the photonic crystal on the surface, as it turned out, reduces the absorption of light and, therefore, heating of the wings. The sea mouse already has been using photonic crystals in practice for a long time. 12"> there is no heating and photochemical destruction of the pigment" title="Advantages of filters based on photonic crystals over the absorption mechanism (absorbing mechanism) for living organisms: Interference coloring does not require absorption and dissipation of light energy , => no heating and photochemical destruction of pigment"> title="Advantages of PC-based filters over the absorption mechanism (absorbing mechanism) for living organisms: Interference coloring does not require absorption and dissipation of light energy, => there is no heating and photochemical destruction of the pigment"> !}

Morpho didius a rainbow-colored butterfly and a micrograph of its wing as an example of diffractive biological microstructure. Iridescent natural opal (semi-precious stone) and an image of its microstructure, consisting of densely packed spheres of silicon dioxide. 13

Classification of photonic crystals 1. One-dimensional. In which the refractive index periodically changes in one spatial direction as shown in the figure. In this figure, the symbol Λ represents the period of change of the refractive index, and the refractive indices of two materials (but in general any number of materials can be present). Such photonic crystals consist of layers of different materials parallel to each other with different refractive indices and can exhibit their properties in one spatial direction, perpendicular to the layers. 14

2. Two-dimensional. In which the refractive index periodically changes in two spatial directions as shown in the figure. In this figure, a photonic crystal is created by rectangular regions of refractive index n1 that are in a medium of refractive index n2. In this case, regions with refractive index n1 are ordered in a two-dimensional cubic lattice. Such photonic crystals can exhibit their properties in two spatial directions, and the shape of regions with refractive index n1 is not limited to rectangles, as in the figure, but can be any (circles, ellipses, arbitrary, etc.). The crystal lattice in which these areas are ordered can also be different, and not just cubic, as in the above figure. 15

3. Three-dimensional. In which the refractive index periodically changes in three spatial directions. Such photonic crystals can exhibit their properties in three spatial directions, and they can be represented as an array of volumetric regions (spheres, cubes, etc.) ordered in a three-dimensional crystal lattice. 16

Applications of photonic crystals The first application is spectral channel separation. In many cases, not one, but several light signals travel along an optical fiber. Sometimes they need to be sorted - each one needs to be sent along a separate path. For example, an optical telephone cable through which several conversations occur simultaneously at different wavelengths. A photonic crystal is an ideal means for “cutting out” the required wavelength from a flow and directing it to where it is required. The second is a cross for light fluxes. Such a device, which protects light channels from mutual influence when they physically intersect, is absolutely necessary when creating a light computer and light computer chips. 17

Photonic crystal in telecommunications Not many years have passed since the start of the first developments before it became clear to investors that photonic crystals are optical materials of a fundamentally new type and that they have a brilliant future. The development of photonic crystals in the optical range will most likely reach the level of commercial application in the telecommunications sector. 18

21

Advantages and disadvantages of lithographic and holographic methods for obtaining PCs Pros: high quality of the formed structure. Fast production speed Convenience in mass production Disadvantages expensive equipment required, possible deterioration in edge sharpness Difficulty in manufacturing installations 22

A close-up view of the bottom shows the remaining roughness of about 10 nm. The same roughness is visible on our SU-8 templates produced by holographic lithography. This clearly shows that this roughness is not related to the fabrication process, but rather is related to the final resolution of the photoresist. 24

To move fundamental PBGs in telecom mode wavelengths from 1.5 µm and 1.3 µm, it is necessary to have an in-plane rod spacing of the order of 1 µm or less. The manufactured samples have a problem: the rods begin to touch each other, which leads to an undesirable large fraction filling. Solution: Reducing the diameter of the rod, hence the filling of the fraction, by etching in oxygen plasma 26

Optical properties of photonic crystals The propagation of radiation inside a photonic crystal, due to the periodicity of the medium, becomes similar to the movement of an electron inside an ordinary crystal under the influence of a periodic potential. Under certain conditions, gaps form in the band structure of PCs, similar to forbidden electronic bands in natural crystals. 27

A two-dimensional periodic photonic crystal is obtained by forming a periodic structure of vertical dielectric rods mounted in a square-cavity manner on a silicon dioxide substrate. By positioning “defects” in a photonic crystal, it is possible to create waveguides that, when bent at any angle, give 100% transmission Two-dimensional photonic structures with a bandgap 28

A new method for obtaining a structure with polarization-sensitive photonic band gaps. Development of an approach to combining the structure of a photonic band gap with other optical and optoelectronic devices. Observation of the short- and long-wavelength boundaries of the range. The goal of the experience is: 29

The main factors that determine the properties of a photonic bandgap (PBG) structure are the refractive contrast, the proportion of high and low index materials in the lattice, and the arrangement of lattice elements. The waveguide configuration used is comparable to a semiconductor laser. An array of very small (100 nm in diameter) holes were etched into the core of the waveguide, forming a hexagonal array of 30

Fig. 2 a Sketch of the lattice and Brillouin zone, illustrating the directions of symmetry in a horizontal, closely “packed” lattice. b, c Measurement of transmission characteristics on a 19 nm photonic array. 31 Brillouin zones with symmetric directions Real Space lattice Transmission

Fig.4 Snapshots of the electric field profiles of traveling waves corresponding to band 1 (a) and band 2 (b), near point K for TM polarization. In a, the field has the same reflection symmetry about the y-z plane as a plane wave, so it should easily interact with the incoming plane wave. In contrast, in b the field is asymmetric, which does not allow this interaction to occur. 33

Conclusions: PBG structures can be used as mirrors and elements for direct emission control in semiconductor lasers Demonstration of PBG concepts in waveguide geometry will allow the implementation of very compact optical elements Incorporation of localized phase shifts (defects) into the grating will allow the production of a new type of microcavity and highly concentrated light , that it will be possible to use nonlinear effects 34

In the last decade, the development of microelectronics has slowed down, since the speed limits of standard semiconductor devices have almost been reached. An increasing number of studies are devoted to the development of alternative areas to semiconductor electronics - these are spintronics, microelectronics with superconducting elements, photonics and some others.

The new principle of transmitting and processing information using light rather than electrical signals can accelerate the onset of a new stage of the information age.

From simple crystals to photonic ones

The basis of electronic devices of the future may be photonic crystals - these are synthetic ordered materials in which the dielectric constant changes periodically within the structure. In the crystal lattice of a traditional semiconductor, the regularity and periodicity of the arrangement of atoms leads to the formation of a so-called band energy structure - with allowed and forbidden bands. An electron whose energy falls within the allowed band can move around the crystal, but an electron with energy in the bandgap becomes “locked.”

By analogy with an ordinary crystal, the idea of a photonic crystal arose. In it, the periodicity of the dielectric constant causes the appearance of photonic zones, in particular, the forbidden zone, within which the propagation of light with a certain wavelength is suppressed. That is, being transparent to a wide spectrum of electromagnetic radiation, photonic crystals do not transmit light with a selected wavelength (equal to twice the period of the structure along the length of the optical path).

Photonic crystals can have different dimensions. One-dimensional (1D) crystals are a multilayer structure of alternating layers with different refractive indices. Two-dimensional photonic crystals (2D) can be represented as a periodic structure of rods with different dielectric constants. The first synthetic prototypes of photonic crystals were three-dimensional and created back in the early 1990s by employees of the research center Bell Labs(USA). To obtain a periodic lattice in a dielectric material, American scientists drilled cylindrical holes in such a way as to obtain a three-dimensional network of voids. In order for the material to become a photonic crystal, its dielectric constant was modulated with a period of 1 centimeter in all three dimensions.

Natural analogues of photonic crystals are the mother-of-pearl coatings of shells (1D), the antennae of a sea mouse, a polychaete worm (2D), the wings of an African swallowtail butterfly and semi-precious stones, such as opal (3D).

But even today, even using the most modern and expensive methods of electron lithography and anisotropic ion etching, it is difficult to produce defect-free three-dimensional photonic crystals with a thickness of more than 10 structural cells.

Photonic crystals should find wide application in photonic integrated technologies, which in the future will replace electrical integrated circuits in computers. When transmitting information using photons instead of electrons, power consumption will be sharply reduced, clock frequencies and information transfer speed will increase.

Titanium Oxide Photonic Crystal

Titanium oxide TiO 2 has a set of unique characteristics, such as a high refractive index, chemical stability and low toxicity, which makes it the most promising material for creating one-dimensional photonic crystals. If we consider photonic crystals for solar cells, titanium oxide wins here due to its semiconductor properties. Previously, an increase in the efficiency of solar cells was demonstrated when using a semiconductor layer with a periodic photonic crystal structure, including titanium oxide photonic crystals.

But so far, the use of photonic crystals based on titanium dioxide is limited by the lack of reproducible and inexpensive technology for their creation.

Employees of the Faculty of Chemistry and the Faculty of Materials Sciences of Moscow State University - Nina Sapoletova, Sergei Kushnir and Kirill Napolsky - have improved the synthesis of one-dimensional photonic crystals based on porous titanium oxide films.

“Anodization (electrochemical oxidation) of valve metals, including aluminum and titanium, is an effective method for producing porous oxide films with nanometer-sized channels,” explained Kirill Napolsky, head of the electrochemical nanostructuring group, Candidate of Chemical Sciences.

Anodization is usually carried out in a two-electrode electrochemical cell. Two metal plates, the cathode and the anode, are lowered into the electrolyte solution, and an electrical voltage is applied. Hydrogen is released at the cathode, and electrochemical oxidation of the metal occurs at the anode. If the voltage applied to the cell is periodically changed, a porous film with a porosity of a given thickness is formed on the anode.

The effective refractive index will be modulated if the pore diameter changes periodically within the structure. Previously developed titanium anodizing techniques did not make it possible to obtain materials with a high degree of periodic structure. Chemists from Moscow State University have developed a new method for anodizing metal with voltage modulation depending on the anodizing charge, which makes it possible to create porous anodic metal oxides with high precision. Chemists demonstrated the capabilities of the new technique using the example of one-dimensional photonic crystals made of anodic titanium oxide.

As a result of changing the anodizing voltage according to a sinusoidal law in the range of 40–60 Volts, scientists obtained anodic titanium oxide nanotubes with a constant outer diameter and periodically changing inner diameter (see figure).

“Previously used anodizing techniques did not make it possible to obtain materials with a high degree of periodic structure. We have developed a new technique, the key component of which is in situ(directly during synthesis) measurement of the anodization charge, which makes it possible to highly accurately control the thickness of layers with different porosities in the formed oxide film,” explained one of the authors of the work, candidate of chemical sciences Sergei Kushnir.

The developed technique will simplify the creation of new materials with a modulated structure based on anodic metal oxides. “If we consider the use of photonic crystals made of anodic titanium oxide in solar cells as a practical use of the technique, then a systematic study of the influence of the structural parameters of such photonic crystals on the efficiency of light conversion in solar cells has yet to be carried out,” Sergey Kushnir clarified.

(crystal superlattice), in which an additional field is artificially created with a period that is orders of magnitude greater than the period of the main lattice. In other words, this is such a spatially ordered system with a strict periodic change in the refractive index on a scale comparable to the wavelengths of radiation in the visible and near-infrared ranges. Thanks to this, such gratings make it possible to obtain allowed and forbidden zones for photon energy.

In general, the energy spectrum of a photon moving in a photonic crystal is similar to the spectrum of electrons in a real crystal, for example, in a semiconductor. Forbidden zones are also formed here, in a certain frequency range in which the free propagation of photons is prohibited. The modulation period of the dielectric constant determines the energy position of the band gap and the wavelength of the reflected radiation. And the width of the band gaps is determined by the contrast of the dielectric constant.

The study of photonic crystals began in 1987 and very quickly became fashionable for many leading laboratories in the world. The first photonic crystal was created in the early 1990s by Bell Labs employee Eli Yablonovitch, who now works at the University of California. To obtain a 3-dimensional periodic lattice in an electrical material, through an Eli mask, Yablonovich drilled cylindrical holes in such a way that their network in the volume of the material formed a face-centered cubic lattice of voids, while the dielectric constant was modulated with a period of 1 centimeter in all 3 dimensions.

Consider a photon incident on a photonic crystal. If this photon has an energy that corresponds to the band gap of a photonic crystal, then it will not be able to propagate in the crystal and will be reflected from it. And vice versa, if the photon has an energy corresponding to the energy of the allowed zone of the crystal, then it will be able to propagate in the crystal. Thus, a photonic crystal has the function of an optical filter, transmitting or reflecting photons with certain energies.

In nature, the wings of the African swallowtail butterfly, peacocks and semi-precious stones such as opal and mother of pearl have this property (Fig. 1).

Photonic crystals are classified according to the directions of periodic change in the refractive index in the measurement:

| 1. One-dimensional photonic crystals. In such crystals, the refractive index changes in one spatial direction (Fig. 1). One-dimensional photonic crystals consist of layers of materials parallel to each other with different refractive indices. Such crystals exhibit properties only in one spatial direction perpendicular to the layers. |

|

| 2. Two-dimensional photonic crystals. In such crystals, the refractive index changes in two spatial directions (Fig. 2). In such a crystal, regions with one refractive index (n1) are located in a medium of another refractive index (n2). The shape of the regions with a refractive index can be any, just like the crystal lattice itself. Such photonic crystals can exhibit their properties in two spatial directions. |

|

| 3. Three-dimensional photonic crystals. In such crystals, the refractive index changes in three spatial directions (Fig. 3). Such crystals can exhibit their properties in three spatial directions. |

|