In contact with

classmates

progenitors inkjet ink were ordinary ink for writing and drawing. Their history goes back to ancient times.

An artifact is kept in the Cairo Museum - a writing instrument, consisting of an ink bottle, a writing stick and a sand pad that served as blotting paper. Approximately V thousand years ago, this device belonged to a court scribe in ancient Egypt.

During excavations in the ancient Roman city of Herculaneum on the shores of the Gulf of Naples, archaeologists discovered an earthenware vessel, at the bottom of which there were dried black ink - soot diluted in oil. By the way, a similar recipe for making ink III thousands of years ago was used by the Egyptians, who burned the roots of the aquatic papyrus plant, and the resulting ash was mixed with gum, a vitreous mass flowing from damaged wood tissues of cherries or acacia.

The papyrus plant, whose roots were used in ancient Egypt to make ink

In China, 2.5 thousand years ago, black ink was made from a mixture of soot, vegetable resin and an alkaline solution. Such ink was very thick, so they were applied to parchment not with pens, but with brushes. After drying, they easily separated from the carrier, especially at the folds.

To this day, recipes for ink from a decoction of the peel of green chestnuts, from ripe blueberries and elderberries, from the peel of walnuts have been preserved.

|

|

| Chestnut | Blueberry |

|

|

| black elderberry | Walnut |

Plants used to make ink in ancient times

One of the ancient Roman recipes called for the use of large quantities of grapes to make ink. Such grapes had to be eaten, and the seeds were collected, dried and burned to obtain soot, which was a natural natural dye. To give the ink the required viscosity and consistency, the soot was combined and thoroughly mixed with a small amount of vegetable oil. After that, grape seed ink was ready to be used.

Grapeseeds - raw material for the production of ink

Even ancient people noticed that octopuses and cuttlefish, in a moment of danger, release a camouflage ink bomb from special bags. People began to use the ink liquid of cephalopods for writing and drawing. To do this, ink bags were removed from the body of octopuses and cuttlefish, dried in the sun, ground into dust, mixed with lye, heated, treated with sulfuric acid, dried again in the sun and placed under a press. As a result of these manipulations, a dye called sepia was obtained, which is still used to make inks and paints.

|

|

Natural sepia was made from the ink bag of octopuses and cuttlefish

But the best black ink was made from rounded growths on oak leaves - galls. Such outgrowths are formed when the nutcracker insect lays its larvae in the tissue of the leaf. The tree, protecting itself from the invasion of larvae, surrounds them with a dense ring of overgrown shell. It was these growths that in ancient times were ground into fine dust, insisted on water, and glue and copper sulfate were added to the resulting mixture. Such ink had a pleasant sheen and looked as if it had just come out from a scribe's pen. Walnut ink had one drawback: the first 10-12 hours after application, they remained completely transparent, and only after some time they darkened and acquired shine.

Growths - galls on oak leaves

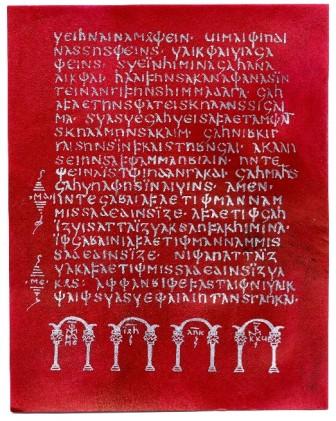

Byzantine and Russian scribes produced gold and silver ink to decorate religious books. For this, a small pea of molasses was combined with the thinnest gold or silver leaves. The resulting mixture was thoroughly mixed to a homogeneous consistency and used for writing. Then the honey was carefully washed out, and elegant golden letters remained. Sweden still has a purple bible written in silver ink. The age of this "silver" bible is about 1.5 thousand years.

Bible written in silver ink

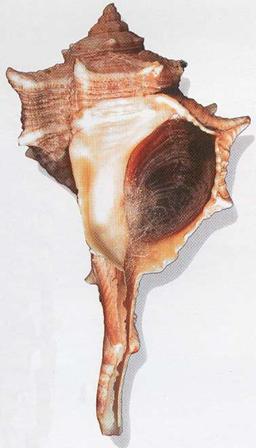

In Greece and ancient Rome in the III century. BC. red royal ink was made from cinnabar and purple. Purple was obtained from the bodies of brandaris mollusks, which were removed from the shells, placed in salt water, then dried in the sun and boiled. Out of 10,000 shellfish, only 1 gram of magenta ink was produced. According to rough calculations, 1 kg of purple ink should have cost 45,000 gold marks. Red ink, under pain of death, was forbidden to be used outside the imperial court. Special guards were assigned to them, who were responsible for the safety of the ink with their own heads.

Bolinus brandaris, from which purple ink was made in Ancient Greece and Ancient Rome

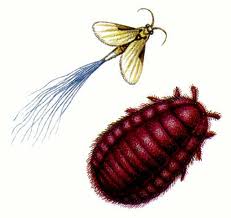

In Russia, there were no such strictness associated with purple ink. They learned to make worms from insects, which were dried and crushed into powder. Red ink was used by Russian scribes to highlight a paragraph, the so-called "red line". It got its name due to the fact that at the beginning of each section the first letter was painted in red ink in the form of a picture. This facilitated the division of the text into chapters and its perception.

Larvae of the carminous mealybug, from which red ink was made in Russia

The riddle of ruby, sapphire and mother-of-pearl inks, which are called "precious stone ink", has not yet been solved. The recipe for making such ink was kept in strict confidence by the Mongolian monks.

It is believed that the first printing device that used black ink was the press of Johannes Gutenberg, invented in 1456. The press is equipped with removable letters with the image of letters. From such letters it was possible to compose words, phrases and whole sentences. Letters could be used multiple times. They were placed under a press on a paper sheet and thus received prints.

Press by Johannes Gutenberg

The invention of the press by Johannes Gutenberg greatly accelerated the development of inkjet inks.

In 1460 was invented linseed oil printing technology, which made it possible to apply images to metal surfaces. A reliable recipe for linen ink has not survived to this day. It is only known that the main components of such inks were polyoxides and plant pigments.

A few centuries later, vegetable and linseed oils became the main components of ink. Such ink was liquid and dried slowly. At the same time, the first ink was made with the addition of petroleum distillate.

In the 16th century there were iron ink, which were made from alder root, walnut or oak bark and ink nuts, set in a vessel with fragments of iron. When cooking alder bark, tannic acids were released from it, which, interacting with iron fragments, produced ferrous iron salts. Fresh ink had a pale color, but when dry, the iron oxidized and darkened. The resulting prints were stable to light and did not dissolve in water. To give the ink the necessary viscosity and strength, cherry glue (gum), ginger, cloves and alum were added to their composition.

In the 17th century, copper sulphate was used instead of iron fragments in the manufacture of iron ink. This made it possible to speed up the process of making ink. Black ink obtained in this way began to be called in Russia "good ink".

In 1847, a German organic chemist, Professor Runge, made ink from an extract of tropical sandalwood. The sap of this tree contains hematoxylin, which, when oxidized, produces a purple-black pigment. Therefore, the ink developed by Professor Runge had a purple tint.

Professor Runge - inventor of sandalwood ink

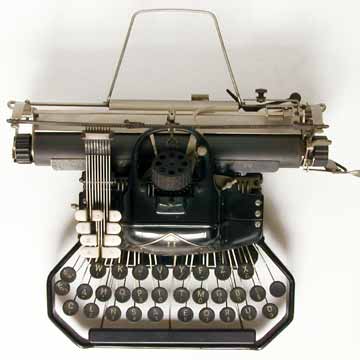

In 1870, 414 years after the invention of the printing press by Johannes Gutenberg, ink was used in the first typewriters. Such typewriters were equipped with an impact mechanism with letter letters and an ink ribbon. Striking the tape, the letters transferred the corresponding ink letters and signs to the paper. One of the first models of typewriters is shown in the figure below.

One of the first typewriters

The next stage in the development of ink was the appearance of alizarin ink, which was invented in 1885 by the Saxon educator Christian Augustan Leonhardi. Leonhardi's ink was made from the juice of gall nuts with the addition of krappa from the roots of the oriental madder plant. Madder mottling gave the colorless hazy gall ink a rich blue-green tint. Later, krapp was replaced with a synthetic dye, and gall nuts were replaced with gallic acid. So alizarin ink became fully synthetic and cheaper to manufacture. Even later, a synthetic dye of a beautiful bright purple color was found. Ink made using such a dye is called aniline.

A century after the invention of alizarin and aniline inks, the first inkjet printing systems were developed in the late 1970s. In 1976, the world saw the first IBM inkjet printer - Model 6640, in 1977 the first inkjet machine rolled off the assembly line of Siemens, in 1978 Canon Corporation announced the development of a new BubbleJet inkjet printing technology, a little later the innovative drop-on-demand inkjet printing technology provided by Hewlett Packard.

The first generation of inkjet printers used water-based ink, consisting of a coloring liquid and water. Due to its homogeneous consistency and the absence of solid particles, aqueous ink impregnates not only the surface, but also the deep layers of the paper. They produce very bright and rich prints, much more colorful than pigmented inks. The advantage of aqueous ink is its economy, the disadvantage is its instability to sunlight and moisture. Such ink quickly fades in the sun and is washed off with plain water. Prints made with water-based ink should be stored in a dry, dark place, preferably in a photo album.

The development of inkjet printing technology has led to the emergence of photo printers designed to print high-quality photographs. These photo printers use pigment inks, which include water, pigments and special additives. Pigments are microscopic particles of organic or non-organic solid matter. The size of such particles is 500 times smaller than the thickness of a human hair, so they freely pass through the nozzles of the print head. The advantage of pigment inks is their resistance to sunlight and moisture, the disadvantage is the lack of brightness compared to water-based inks.

Having made the first pigment inks, manufacturers immediately began to improve their composition. Today, the chemical industry is working to improve the realism and color variety of inkjet inks, reduce droplet size, improve lightfastness and moisture resistance, and more.

Inkjet color schemes are expanding. If the first inkjet printers were equipped with four-color cartridges with a standard set of CMYK colors (black, yellow, magenta and cyan), today they produce extended CMYK schemes, consisting of six, eight and even eleven colors.

Innovative developments in the field of inkjet printing include sympathetic ink, which are exposed to ultraviolet radiation, disappearing ink which discolor when heated fluorescent ink that glow in the dark, silver ink, conducting electrical impulses, textile ink, which print excellently on fabric, latex, which include artificial latex polymers and some other types of inks. These inks are the future of inkjet printing.

In contact with