IZVESTIYA

TOMSK ORDER OF THE RED BANNER OF LABOR POLYTECHNIC

INSTITUTE NAMED AFTER S. M. KIROV

TECHNOLOGY FOR OBTAINING SOLUBLE HUMATES FROM

N. M. SMOLYANINOVA, S. I. KHOROSHKO, A. N. MOSKALCHUK

Recently, humic acids have been increasingly used in various sectors of the national economy. They, in the form of soluble sodium salts (humates), are successfully used as stabilizers for clay solutions used in oil drilling, as well as for the manufacture of wood dyes. Due to their good surface-active properties, humic acids are used in the battery industry as an extender for the positive plates of batteries. And finally, the use of humic acids in the form of soluble humates in agriculture as growth stimulants is very promising. Their high efficiency has been proven in numerous works by Professor L.A. Khristeva and her colleagues and other authors.

Currently, industrial production of humic acids is carried out at the Tyumen Battery Plant. Solid sodium humates for the needs of the furniture industry are produced in small quantities in Latvia at an industrial plant. Both products are in short supply.

Due to the increased demand for humic preparations, it is necessary to organize their industrial production on a large scale. This will make it possible to quickly introduce humic acids and other preparations based on them into industry and agriculture.

Existing technological schemes have a number of serious disadvantages, namely: 1), the frequency of the process and, as a consequence, the cumbersomeness of the hardware, the difficulty of automation, low productivity of installations and high operating costs; 2) high heat consumption; 3) large losses of product and low coefficient of extraction of humic acids.

Of course, if we raise the question of industrial production of acids at the modern level, then we can only talk about a continuous process.

The main difficulty in developing a continuous technology for the production of humates or humic acids is the extreme duration of the process of their extraction from fuel, due to the low rates of diffusion of the active part of the alkaline reagent into solid particles and the resulting humates from the solid into solution, as well as the very specificity of humic acids as high-molecular organic acids , possessing colloidal properties. In addition, from -158

separating the unreacted raw material from the humate solution is difficult, since the crushed fuel, especially peat, swells greatly and is partially peptized in an alkaline solution, forming a very stable suspension that settles very slowly, and it is almost impossible to filter it.

Great difficulties also arise during the process of filtration and drying of humic acids. This implies the need to search for ways to intensify the process 1 as a whole and, first of all, its first stage - the extraction of humic acids from the feedstock in the form of soluble humates.

One of the factors that makes it possible to intensify this process is temperature. It is known that heating a peat-alkaline suspension to a temperature of 80-100 ° C can significantly increase the rate of formation and dissolution of humates. Our experiments have shown that if, when extracted in the cold for 30 minutes. the yield of humic acids from peat is only 5.73%, then already at 50°C it is equal to 12.74%, and when the mixture is boiled -29.72% for the same period of time.

Of significant interest is the so-called dispersion method for the extraction of humic acids, based on fine grinding of the starting material in an alkaline environment. According to G.M. Volkov, this technique increases the yield of the product and reduces the duration of the process, allowing extraction in the cold.

The ultrasonic method for producing humates may have great prospects, allowing one to significantly intensify this process. A.P. Grishin and V.Yu. Zorin showed that under the influence of an ultrasonic field, the process of extracting humic acids from brown coal in an alkaline environment is accelerated by approximately 20 times.

In the problem laboratory of TPI peat, research was carried out to determine the possibilities of dispersive and ultrasonic methods of process intensification in relation to peat. The influence of the type, consumption and concentration of the alkaline reagent, process temperature and intensity of mixing of the peat-alkaline mixture on the rate of extraction of humic acids was studied. In addition, methods for separating the peat-humate suspension were tested - settling, filtering, centrifugation, the effect of polyacrylamide (as a flocculant) .

Based on the discussion of our results, as well as data from the analysis of the work of existing enterprises and literature data, the following conclusions were made:

1. Mechanical dispersion of peat in an alkaline environment can significantly intensify the process of extracting humic acids from peat and can be the basis of the technological process being developed in combination with subsequent heating of a fine peat-alkaline suspension to a temperature of 80-100°C. This will reduce the duration of the peat treatment process with an alkaline solution to 30-60 minutes and carry out extraction at a lower alkali consumption, i.e., with a peat: alkaline solution ratio of 1: 10, compared to 1: 100, which is optimal for conventional extraction method.

2. Solutions of caustic soda or soda can be used as reagents; the latter is much cheaper and its use is more economical.

3. To separate the humate solution from the peat residue, it is advisable to use a settling type centrifuge.

4. In the case of using caustic soda as a reagent, it may be recommended to use it twice: the first time in the form

pure solution, in the second - in the form of an alkaline humate obtained during the first extraction.

5. Intensification of the process of extracting humic acids by combining fine dispersion of peat in an alkaline medium with subsequent heating of peat to boiling point with intense stirring provides the basis for the development of a continuous technological scheme for the production of humates, as well as (if necessary) humic acids.

6. It is advisable to construct a large installation for the production of solid humate or a concentrated solution intended for the centralized supply of various consumers (agriculture, furniture industry, oil fields). Concentration of the solution is easily accomplished by evaporation.

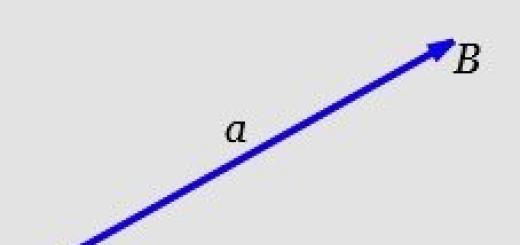

Rice. 1. Technological scheme for the production of sodium humates: 1 - bunker for raw materials, 2 - elevator, 3 - intermediate bunker, 4 - hammer crusher, 5 - mixing screw, 6 - container for solution, 7 - collection tank, 8 - mechanical dispersant , 9 - reactor, 10 - precipitation centrifuge, 11 - evaporator, 12 - surface condenser, 13 - vacuum pump, 14 - humate collector, 15 - pump, 16 -

The above conclusions form the basis for the development of a continuous version of the technological scheme for the process of obtaining humates based on peat from the Taganskoye deposit in the Tomsk region. The productivity of the installation was determined approximately based on the need for humic acids in the main regions of the region with developed vegetable growing, since the use of humic fertilizers is most effective for vegetable crops.

A 2% soda ash solution was used as a reagent. Despite its lower activity, soda provides a sufficient degree of extraction of humic acids when combined with fine 160

dispersing peat in an alkaline medium, followed by heating the mixture to 80-100°C for 0.5-1.0 hours with intensive stirring. The ratio (weight of peat to volume of soda solution is 1: 10.

To separate the peat-alkaline suspension, a settling centrifuge 2NOGSH-300 is used (7).

The technological flow diagram of the process is shown in Fig. 1.

Air-dry peat in the form of crumbs is fed from the hopper (1) by a bucket elevator (2) through an intermediate hopper (3) into a hammer crusher (4), where it is crushed to a piece size of no more than 1-2 mm. Crushed peat is mixed in a mixing screw (5) with a soda solution supplied from a container (6). Then the peat-alkaline mixture enters the mechanical disperser (8), from where it is fed into the reactor (9). In the reactor, the final extraction of humic acids occurs by heating and stirring the suspension with live steam entering through the ejector. Unreacted peat is separated from the humate solution in a sedimentation centrifuge (10). The latter has two screws, which makes it possible to wash the sediment with a separate drainage of wash water, which (in order to reduce the loss of humates) is fed into a container (7) for preparing a soda solution.

The washed sediment goes to the dump, and a weak solution of humates (2.0%) is evaporated in an evaporator (11) to a concentration of 15% and enters the collection (14).

Secondary steam from the evaporator is condensed in a surface condenser (12). Hot condensate can be used to wash the sediment: in a centrifuge. The vacuum in the system is created by a vacuum pump (13).

As economic calculations showed, the total cost of humates was 465 rubles. per ton.. The high cost of production is explained by the low productivity of the installation, since most of the costs (about 60%) fall on wages and operating costs. These "costs can be reduced by building larger plants.

The economic effect from the use of sodium humates averaged 8-10 rubles. for every hectare of crops.

LITERATURE

1. Sat. “Humic fertilizers. Theory and practice of their application", part I, Selkhozich-dat of the Ukrainian SSR, Kyiv, 1957.

2. Sat. “Humic fertilizers. Theory and practice of their application”, part II. Selkhozdat of the Ukrainian SSR. Kyiv. 1962.

3. G. M. Volkov. On technologies for the production of humic acids. Proceedings of the Institute of Geography of the USSR Academy of Sciences, vol. XII, 65-76. 1961.

4. A. P. Grishin, .V. Yu. Zorin Ultrasonic method for isolating humic substances, Proceedings of the Grozny Oil Institute, Coll. 25, no. 3, 59-62. 1961.

5. N. M. Smolyaninova, A. N. Moskalchuk. Study of the process of obtaining humic acids from peat. Izv. TPI. In the press.

6. Development of technology for producing humic acids based on peat. Report on topic 162/63. Tomsk 1965.

7. Centrifuges. Directory catalogue. Mashgiz, 1955.

1The article shows that the unique economic-geographical, transport and geopolitical position of the Far Eastern Federal District is a direct prerequisite for the implementation of its breakthrough socio-economic development. In order to solve the problems of the region and its development, the Government of the Russian Federation adopted the Federal Target Program “Economic and Social Development of the Far East and the Baikal Region for the Period until 2025”, territories of rapid socio-economic development are being created, and the “Far Eastern Hectare” program is in effect to secure labor resources “, within the framework of which land plots are provided free of charge for agriculture, forestry and hunting or any other type of business. Therefore, there is a need to protect the region in advance from environmental problems, in particular problems with soil degradation and pollution. One of the ways to restore soil fertility and detoxify it is to introduce humic substances into the soil, which can be successfully extracted from peat, brown coal, and sapropel. At the Institute of Mining of the North named after. N.V. Chersky SB RAS has developed a method for producing humic substances from brown coals and peat, a pilot plant for the production of liquid and dry humates has been developed, manufactured and tested. Humates obtained using the IGDS SB RAS method are completely soluble in water (i.e., they belong to the “ballast-free” category), which is the most preferred type of artificially obtained humic substances for soil restoration. The authors note the need to create in this direction methodological and organizational foundations for agroecological restoration of fertility, making forecasts for the evolution of soils both under anthropogenic influences and for agrotechnical measures.

detoxification

restoration of fertility

brown coal

humic substances

“ballast-free” humates

1. Economic and social development of the Far East and the Baikal region for the period until 2025: federal. target program [Electronic resource]. URL: https://urexpert.online/wp-content/uploads/2017/03/DVBR2025.pdf (access date: 11/16/17).

2. Gavrilov V.L. Assessment of the state of open-pit mining of coal deposits in Central and Northern Yakutia / V.L. Gavrilov, S.A. Ermakov, D.V. Khosoev // Mining information and analytical bulletin. – 2010. – No. 11. – P. 29–36.

3. Moskalenko T.V. Preparation of coal-water suspensions from coal from the South Yakut coal basin / T.V. Moskalenko, V.A. Mikheev, E.V. Chasovenko // News of higher educational institutions. Mining magazine. – 2014. – No. 4. – P. 113–120.

4. Cheban A.Yu. Equipment and technologies for developing coal mines in the Amur region and prospects for their development / A.Yu. Cheban, N.P. Khrunina // Mine surveying and subsoil use. – 2015. – No. 1. – P. 19–21.

5. Prospects for the development of the Far Eastern region and environmental aspects of mining operations / A.Yu. Cheban [et al.] // Systems. Methods. Technologies. – 2015. – No. 3 (27). – pp. 156–161.

6. Vernadsky V.I. Chemical structure of the Earth’s biosphere and its environment / V.I. Vernadsky. – M.: Nauka, 1965. – 374 p.

7. Orlov D.S. Soil chemistry / D.S. Orlov, L.K. Sadovnikova, N.I. Sukhanov. – M: Higher School, 2005. – 560 p.

8. Pat. 2174529 Russian Federation, MKI C 10 G 1/04, C 05 F 11/2. Method for obtaining humic substances / Novopashin M.D., Bychev M.I., Mikheev V.A., Petrova G.I., Moskalenko T.V.; applicant and patent holder Institute of Mining of the North SB RAS. – No. 99122182/04; application 10/22/99; publ. 10.10.2001, Bull. No. 28. – 6 p.

9. Moskalenko T.V. Brown coals of the Republic of Sakha (Yakutia) as raw materials for the production of humic substances / T.V. Moskalenko, V.A. Mikheev // Exploration and protection of subsoil. – 2015. – No. 3. – P. 24–27.

The Far Eastern Federal District (FEFD) is the largest in Russia in terms of territory and has a unique economic-geographical, transport and geopolitical position in relation to the countries of the Asia-Pacific region, the population of which is almost half of the global one. The Far Eastern Federal District has a number of favorable factors for further socio-economic development. The most significant of them are: the unique natural resource potential not only on land, but also at sea; availability of railways (Trans-Siberian and BAM); border position; ice-free seaports in the south; favorable conditions for the development of agriculture in the south. On the other hand, extreme natural and climatic conditions, poor development and inaccessibility of the territory, increased seismicity are unfavorable natural factors. To this we can add the remoteness of the territory from industrialized areas of the country, insufficient development of the road network, instability and, consequently, constant outflow of population. The current structure of the region's economy has a clearly defined raw material orientation, which also hinders the development of the Far East.

In order to solve the problems of the region and its development, the Government of the Russian Federation adopted the Federal Target Program “Economic and Social Development of the Far East and the Baikal Region for the Period until 2025” , within the framework of which it is planned to create modern complexes of engineering and transport infrastructure, leading to the progressive development of the territories. Investment projects involving extra-budgetary funds are focused on the development and development of the mineral resource base of the macroregion, including the mining industry and the fuel and energy complex, as well as the modernization and construction of processing plants. It is planned to develop large deposits of coal, iron ore, and building materials. The creation of processing plants within the framework of the Federal Target Program (for example, the Eastern Petrochemical Complex and the Nakhodka Mineral Fertilizer Plant in the Primorsky Territory, the Garinsky Mining and Processing Plant in the Amur Region, etc.) entails an increase in the burden on the environmental situation in the region.

An instrument for the development of the Far Eastern Federal District, oriented towards global competitiveness, should be the created territories of advanced socio-economic development (ASED), when working in which residents are provided with large-scale tax benefits. In terms of attracting and retaining labor resources in the Far East, there is a “Far Eastern Hectare” program, within the framework of which land plots are provided free of charge. The plot is allowed to be used for the construction of a private house, and the land - for farming, forestry, hunting or any other type of business.

In this regard, the threat of a global environmental crisis in the region due to soil degradation is increasing. Disturbance of the soil layer occurs not only as a result of water and wind erosion, but also when soil is polluted with waste from mining (various ores, building materials, oil, gas) and the creation of additional landfills for industrial and household waste. Particular attention should be paid to heavy metals, as well as radioactive elements and pesticides used in agriculture.

The role of soil in the history of the earth's crust does not at all correspond to the thin layer it forms on its surface. But it fully corresponds to the enormous active energy that is collected in the living matter of the soil. Soil is the main component of the biosphere and performs basic functions. First of all, this is the biotic cycle of substances: land biomass is inextricably linked with the soil cover.

To improve the physical properties of the soil, fertilizers are used, but it must be remembered that the amount of humus in the soil is of no small importance, since thanks to it the plants receive all the necessary nutrients. Humic substances have a direct or indirect effect on plants. Thanks to their indirect influence, microflora is activated, the water-physical properties of the soil are improved, the efficiency of the use of mineral fertilizers increases, and the migration of nutrients is also influenced. An important aspect is the binding of toxic reagents (heavy metals, pesticides, herbicides, etc.). The direct effect lies in the versatile regulatory function of plant growth and development processes.

Natural organic compounds - humic acids are formed during the humification process of products of animal, plant and microbial origin. Most of them are resistant to biochemical breakdown, so they accumulate in the soil and are also part of peats, brown coals, and sapropels. From these sources they can be isolated by alkali solutions in the form of soluble salts - humates.

A large number of field tests have shown that humic acids isolated from coal and peat have all the qualities of native soil humic acids. The extraction of these acids from different types of raw materials is based on their ability to dissolve in alkaline solutions of potassium and sodium. Derivatives of such dissolution - humates (salts of humic acids) are highly soluble in water and have physiologically active properties.

Research results and discussion

The effect of humates is to a greater extent regulatory, and to a lesser extent fertilizing, so researchers do not directly attribute them to either plant hormones or fertilizers. Research into the characteristics of these substances and their effects continues. At the moment, humates are considered to be completely new agrochemicals that have a beneficial effect on all types of plants.

There are few fakes on the market among humates, since the production of counterfeit products is much more expensive than production using the correct technology, but humic preparations coming to the market from various manufacturers differ significantly in their properties depending on the type of raw materials, the method of production of the drug and the form of the finished product. product.

Humic substances are isolated from solid combustible minerals in two ways: the first, classical method, in which alkaline extraction is carried out with potassium or sodium hydroxides, the second, alternative method, involves mechanical grinding of brown coal with solid alkali. The remaining existing methods are variations of these two and are aimed at reducing the disadvantages of each of them. The main disadvantage of the classical method is the low yield of humic substances, comparable to the yield of free humic acids from the feedstock. An alternative method leads to the production of so-called “ballast” humates, the disadvantage of which is the high content of insoluble residue. The introduction into the technological process of physical methods of influencing coal, temperature extraction and filtration of the resulting solution leads to an increase in the cost of their production, but makes it possible to obtain “ballast-free” humates with high yield.

Humic substances include the following components:

Humic acids are soluble only in alkaline solutions;

Fulvic acids are soluble in water, alkaline and acidic solutions (they are released after the separation of humic acids by precipitation and form the resulting filtrate);

Hymatomelanic acids extracted from the crude residue (gel) of humic acids with ethyl alcohol;

An organic substance that is practically insoluble and cannot be extracted is humin.

Thus, humic substances are composite and, in addition to the above components, also include microelements.

These groups of humic acids are usually referred to in the plural (e.g., humic acids) because their composition and properties vary depending on the source of the humic substances. Research has proven that even in preparations obtained from the same source (one type of soil, peat, coal), humic substances are heterogeneous, polydisperse and are represented by a large set of similar in structure, but non-identical molecules.

“Ballast-free” humates, that is, completely soluble in water, are more often called drugs or growth stimulants, and “ballast” humates, that is, humates containing insoluble sediment in one quantity or another, are more often called fertilizers. This gradation determines different methods of their application and dosages applied to the soil.

To artificially obtain humic acids, potassium or sodium salts are used, and in some cases the use of ammonium salts is allowed; therefore, artificially obtained humates are usually divided into types depending on the type of alkali used for extraction. Most often, potassium or sodium salts are used for production, but in some cases the use of ammonium salts is also allowed. The most common is potassium humate. It has optimal acidity, is neutral in chemical reactions, and additional enrichment with microelements allows it to be used not only for processing planting material, but also for feeding and stimulating the growth of seedlings. Sodium humate has a smaller scope of application because it has a higher pH value (up to 10 units), and its use on alkaline soils is contraindicated. But all types of artificially obtained humic substances have the ability to increase plant resistance to diseases, frosts, drought and other unfavorable conditions.

In agriculture, humates are currently used in several ways: firstly, solutions of “ballast-free” humates are used for pre-sowing treatment of seeds, and secondly, during the period of growth and fruiting - for fertilizing with weak solutions. To detoxify the soil, it is preferable to use dry “ballast-free” types of humic substances. As research in the field of obtaining humic substances and creating humic preparations continues, the scope of their application is constantly expanding. In particular, the effectiveness of these products has been proven when treating poor greenhouse soils.

At the Institute of Mining of the North named after. N.V. Chersky SB RAS developed a method for obtaining humic substances from brown coals. In accordance with this technology, brown coal is mixed with alkali and subjected to heat treatment, followed by extraction of humic substances with water. Based on this method, a pilot plant for the production of liquid humates was developed, manufactured and tested. To obtain dry humates, a drying unit is added to the technological scheme. The product of such processing is “ballast-free” physiologically active potassium or sodium humates.

Currently, the raw material for the production of humates is brown coal from the Lena coal basin. The use of peat as a raw material (Neryungri region, Republic of Sakha (Yakutia)) also showed high results both in terms of the efficiency of the extraction process and the quality characteristics of the resulting product. Testing of the installation in pilot industrial conditions showed its high efficiency from a technological point of view and good physiological activity in terms of subsequent use.

Based on the results of these tests, the following indicators were achieved:

The yield of liquid humates from brown coals of the Kangalas deposit was 50-56% (with a yield of free humic acids of 17.9%), from brown coals of the Kirov deposit it was 70-77% and was 4 times higher than the yield of free humic acids from this coal (18. 2%), from peat amounted to 54-61% (with a yield of free humic acids of 25.4%);

The yield of dry humates from brown coals of the Kangalas deposit was more than 80%, from brown coals of the Kirov deposit - 78-86%, and from peat - more than 61-73%.

In the practice of using humic substances, the correct preparation of solutions for watering and spraying plants is of great importance. When diluting solutions, humic acids are taken as the main substance from all organic substances contained in the humate. Modern recommendations for the use of this class of drugs consider the following concentrations of humic substances to be the most effective for the purpose of use:

Pre-sowing soaking of seeds involves the use of working solutions with a concentration of 0.01 to 0.08% of the main substance; seed soaking is carried out from 2-3 hours to 1-2 days;

Foliar feeding during the growing season is carried out with working solutions with a concentration of the main substance from 0.001 to 0.008%, foliar feeding during the growing season is carried out 2-3 times per season;

Root feeding is also carried out with working solutions with a concentration of the main substance from 0.001 to 0.008% up to 3-4 times per season with a frequency of 1 time in 14-15 days, starting from the emergence of seedlings or after planting seedlings;

Soil restoration (reclamation) is recommended to be carried out with working solutions with a concentration of 0.1 to 0.2% of the main substance, while humate is applied either directly to the soil, or it is used to treat straw with its subsequent incorporation into the soil. At the same time, in addition to restoring fertility, the process of binding harmful substances in the soil and converting them into a form that is not absorbed by plants also occurs.

Humates obtained using the IGDS SB RAS method are completely dissolved in water (i.e. they belong to the “ballast-free” category), the concentration of humic acids (the so-called main substance) in the product produced is in solution when 1 g of dry humates is dissolved in 1 liter of water for different samples it varies from 0.16 to 0.29 g/l at pH 8.2-9.2. Dilution to working concentrations reduces the pH to 7-7.2.

Microelements that are so necessary for plant nutrition are transferred from coal to the resulting humic fertilizers. Brown coal (raw materials) and humic preparations obtained from it were tested for the content of 30 metals, including heavy ones. As a result, it was established that the content of “minor” elements in coal and humic preparations obtained from them does not exceed the average background values characteristic of coals from the basins of the former USSR, i.e. the use of humic preparations as fertilizers is environmentally safe.

Determination of biological activity according to GOST R 54221-2010 showed the following results: root growth - 20-66%; stem growth - 70-85%; weight gain - 59-71% (figure).

Changes in plant parameters during their germination under the influence of humates obtained using the IGDS SB RAS method from coals of the Republic of Sakha (Yakutia), compared with the control experiment (aqueous solution without humate): a - root length, mm; b - stem length, mm; c - mass of seedlings, g

Comparative testing was carried out for biological activity on the germination of cucumber, rapeseed, and wheat seeds in a solution of humates obtained using IGDS technology and in solutions of humates from third-party manufacturers. The study showed that the biological activity of humates obtained using the IGDS SB RAS technology significantly exceeds the corresponding indicators of growth in root length, stem length and weight of plants sprouted in solutions of samples of humates from third-party manufacturers, some of which even led to inhibition of seedling growth and a decrease in the rate of growth their masses.

Conclusion

Summarizing the properties of humic acids and the results of their testing, we can conclude that “ballast-free” humic substances are suitable for restoring soil fertility, including with an integrated ecological and economic approach. Researchers have long believed that there is an urgent need to create methodological and organizational foundations in this direction for agroecological restoration of fertility, making forecasts for the evolution of soils both under anthropogenic influences and for agrotechnical measures. And to conduct agricultural production on a scientific basis, it is necessary to periodically test and map soils for their humus content. This will have an impact not only on the provision of plants with nutrients, but also on the intensity of the soil-forming process, which in general will contribute to the sustainable functioning of agricultural systems.

Bibliographic link

Moskalenko T.V., Mikheev V.A., Vorsina E.V. ARTIFICIALLY PRODUCED HUMIC SUBSTANCES FOR SOIL RESTORATION // Advances in modern natural science. – 2018. – No. 1. – P. 109-114;URL: http://natural-sciences.ru/ru/article/view?id=36659 (access date: 02/01/2020). We bring to your attention magazines published by the publishing house "Academy of Natural Sciences"

Khalizev K.A. 1

1 MBOU "Secondary school No. 1. Builder of the Belgorod region"

Meremyanina T.G. 1

1 Municipal budgetary educational institution “Secondary school No. 1 of Stroitel, Yakovlevsky district, Belgorod region”

The text of the work is posted without images and formulas.

The full version of the work is available in the "Work Files" tab in PDF format

|

INTRODUCTION |

||

|

ANALYTICAL REVIEW OF LITERATURE |

||

|

Composition of humic acids |

||

|

The mechanism of action of humic acids in vermicompost |

||

|

Range of produced humus preparations |

||

|

EXPERIMENTAL PART |

||

|

Materials and research methods |

||

|

RESEARCH RESULTS |

||

|

Physico-chemical composition of humus preparation |

||

|

Study of the biological activity of the drug |

||

|

CONCLUSION |

||

|

BIBLIOGRAPHY |

||

|

APPLICATIONS |

INTRODUCTION

Humic substances are complex mixtures of high-molecular dark-colored organic compounds of natural origin, resistant to biodegradation, formed during the decomposition of plant and animal residues under the influence of microorganisms or abiotic environmental factors.

Humic acids can be extracted from humified natural products (peat, brown coal, coal and vermicompost) with aqueous solutions of alkalis.

Humic acids are high-molecular polymer compounds that are insoluble in water and have the property of low mobility. Therefore, for use in agricultural production, they must be transferred as much as possible into a soluble state accessible to plants and animals.

The basis for obtaining humic preparations is their ability to form water-soluble salts with monovalent cations of sodium, potassium and ammonium.

Preparations made on the basis of humic acids contain amino acids, polysaccharides, carbohydrates, vitamins, macro and microelements, and hormone-like substances. They are characterized by stability, multifunctionality and have sorption, ion-exchange and biologically active properties. Humic acids (HA) are characterized by a general type of composition and structure. However, depending on the initial substrate, method of isolation and storage, composition and structure indicators may vary, and in connection with this, their physiological activity changes.

Relevance This research is determined by the need to develop new environmentally friendly biological preparations, the use of which will significantly contribute to increasing crop yields.

Research hypothesis: Humic compounds in dissolved form can be obtained from vermicompost using chemical, physical and mechanical effects.

As theoretical basis and information base of the research The works of domestic authors in the field of agrochemistry and soil science were used. Information sources for writing this work were standards and scientific publications.

Purpose of the study: release of humic substances by using chemical, physical and mechanical effects on vermicompost to maximize the transfer of humic compounds into solution.

To achieve the goal of the work, the following were set: tasks :

study the scientific literature on the composition and mechanism of the influence of humic substances on agricultural plants;

study the range of manufactured humus preparations and methods for their isolation;

master physicochemical methods for isolating humus preparations, as well as test the resulting preparation for compliance with quality and safety;

to study the biological activity of the resulting humus preparation based on the results of its effect on cucumber seeds of the “Dalnevostochny” variety.

Object of study was vermicompost obtained in the mini-vermilaboratory of the Testing Laboratory of the Scientific Research Center "Agrotechnopark" of the V.Ya. Gorin Belgorod State Agricultural Academy from compost worms of the Belgorodskaya hybrid line.

Subject of research steel humic substances isolated from vermicompost.

The following were used in the study: methods: experimental method (extraction and precipitation of humic substances, physicochemical and biological tests of the drug), observation and methods of statistical analysis.

The studies were carried out in the chemical laboratory of the Municipal Budgetary Educational Institution "Secondary School No. 1 of the city of Stroitel, Yakovlevsky District, Belgorod Region" and in the Testing Laboratory of the Federal State Educational Institution of Higher Professional Education of the BelState Agricultural Academy named after. V.Ya.Gorina.

1. ANALYTICAL REVIEW OF LITERATURE

1.1. Composition of humic substances

The history of the study of humic substances goes back more than two hundred years. They were first isolated from peat and described by the German chemist F. Achard in 1786. German researchers developed the first isolation and classification schemes, and also introduced the term itself - “humic substances” (derived from the Latin humus- “earth” or “soil”). The Swedish chemist J. Berzelius and his students made a great contribution to the study of the chemical properties of these compounds in the middle of the 19th century, and then, in the 20th century, our soil scientists and coal chemists: M.A. Kononova, L.A. Khristeva, N. Alexandrova, D.S. Orlov, T.A. Kukharenko and others. In the classic works of L.A. Khristeva and M.M. Kononova was the first to describe the effect of seed treatment with fulvic acids and salts of humic acids (humates) on the growth of primary roots of test cultures.

But then the interest of chemists in humic substances dropped sharply, since it was reliably established that this is not an individual compound, but a complex mixture of macromolecules of variable composition and irregular structure (Fig. 1), to which the laws of classical thermodynamics and the theory of the structure of matter are not applicable. Humus consists of three groups of compounds: specific humic substances, nonspecific organic compounds and intermediate products of decomposition and humification. The third group includes products of partial decomposition of organic residues, which, based on the sum of their characteristics, cannot yet be classified as specific humic substances, but are no longer substances characteristic of living organisms. Specific substances and nonspecific humus compounds are formed as a result of soil formation processes. Nonspecific humus compounds are synthesized in living organisms and enter the soil as part of plant and animal residues. Specific humic substances are formed directly in the soil as a result of humification processes. Among them are prohumic substances, humic acids and humin.

Humin, or non-hydrolyzable residue, is that part of the soil organic matter that is insoluble in acids, alkalis and organic solvents. Prohumic substances are similar to intermediate products of the decomposition of organic residues. Their presence is detected by detailed fractionation of preparations isolated from soil. Humic acids are a class of high-molecular nitrogen-containing hydroxy acids with an aromatic core that is part of humus and is formed during the process of humification.

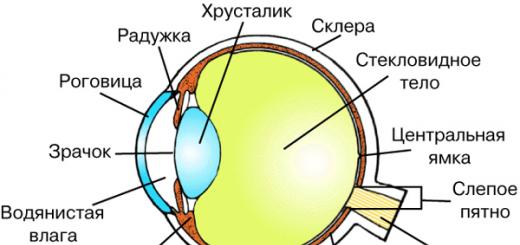

Rice. 1. Formula of the structural cell of humic acid (according to D. S. Orlov)

Based on their different solubility in water, acids, alkalis and alcohol, humic acids are divided into humic acids, hematomelanic acids and fulvic acids. Humic acids are a group of dark-colored humic acids, soluble in alkalis and insoluble in acids. Hymatomelanic acids are a group of humic acids soluble in ethanol. Fulvic acids are a group of humic acids that are soluble in water, alkalis and acids.

Usually, when carrying out analyses, humic acids are extracted from the soil with alkali solutions (0.1-0.5 N NaOH). When the alkaline extract is acidified to pH (1 - 2), humic and hymatomelanic acids precipitate. Only fulvic acids remain in the solution. When the resulting precipitate is treated with ethanol, the hismatomelanic acids pass into the alcohol solution, coloring it cherry-red.

The group of humic acids is divided into two subgroups: black (gray) and brown humic acids. Humic acids enriched with carbon (mainly in chernozem soils) are called black in domestic literature, and gray in foreign literature. Black and brown humic acids can be separated by the salting out method: when treated with 2 N. With NaCl solution, black humic acids coagulate and precipitate.

Humic acids have the following elemental composition: 50-60% carbon, 2-6% hydrogen, 31-40% oxygen and 2-6% nitrogen. Fluctuations in the elemental composition of humic acids are explained by the fact that they are not chemically individual acids of a certain structure, but represent a group of high-molecular compounds similar in composition and properties.

According to gel chromatographic studies, the lower limit of the molecular mass of humic acids is determined by values of 5000-6000 Dalton (D). There are acids with a molecular weight of 400,000-650,000 D. However, the bulk of humic acids have a molecular weight of 20,000-80,000 D.

Thus, humic acids, due to the peculiarities of their molecular structure, actively influence the migration and accumulation of chemical elements in soil and natural water.

1.2.Mechanism of action of humic substances in vermicompost

The mechanisms by which vermicompost exerts its regulatory effect on soil and plants have not been fully revealed. The higher efficiency of using vermicomposts and their fractions on plant growth and development is explained by their influence on protein synthesis, impact on metabolic reactions, reduction in the activity of respiration inhibitors and the manifestation of hormone-like properties. The literature describes several possible main mechanisms of the influence of vermicompost fractions on plants:

1.Optimization of plant root nutrition. Direct supply of nutrients and microelements; mobilization of phosphorus compounds into bioavailable forms; mobilization and transport of transition metal cations (in particular, copper, iron and zinc) in a chelate form available to plants. Optimization of soil properties: providing energy for soil microorganisms and enhancing microbiological activity, enhancing water-holding capacity, strengthening the structure, etc.

2.Optimization of foliar plant nutrition. Vermicompost fractions contain humic and fulvic acids in varying quantities, which, being surfactants, reduce the surface tension of aqueous solutions, thereby increasing the permeability of cell membranes. In turn, this optimizes the throughput of the plant transport system: it accelerates the movement of nutrients. This accelerates energy metabolism, photosynthesis rate and chlorophyll synthesis.

3. The influence of humic substances on the physiological processes of plants. It is assumed that humic substances enhance the synthesis of high-energy adenosine triphosphate (ATP) in cells, which is involved in optimizing plant respiration. Some molecular components of humic substances lead to the formation of growth phytohormones or act as “hormone-like” substances and enhance enzymatic activity, in particular the content of catalase, peroxidase, diphenyl oxidase and invertase. Vermifertilizers affect the detoxification or inactivation of toxicants in the soil - it is usually associated with the sorption capacity of vermicompost, the number of strong and weak acidic functional groups, hydrophobicity, and sorption capacity for heavy metals and xenobiotics.

In the opinion of Demin V.V., Terentyev V.A., Zavgorodneya Yu.A. and Biryukova M.V. The biological effect of humic substances on living organisms is due to the fact that intact molecules of humic substances and the remnants of their intracellular digestion are localized in the cell walls or in the layer directly adjacent to the cytoplasmic membrane. Thus, on the surface of a living cell, a semblance of an active openwork filter appears, capable of performing the following functions:

intercept heavy metal ions, binding them into stable chelate-type complexes;

intercept xenobiotic molecules;

bind free radicals formed in the plasma membrane as a result of lipid peroxidation.

It is known from the literature that humates harmless to humans and animals, do not have allergenic, anaphylactogenic, teratogenic, embryotoxic and carcinogenic properties.

1.3. Range of produced humus preparations

The range of produced metabolic regulators of humic origin:

Huminate - sodium humate. Developed at the Dnepropetrovsk Agricultural Institute, it is sodium salts of the sum of humic acids in powder form. Obtained by alkaline extraction. The drug is classified as a biogenic stimulant;

Humin HS-1500 is a synthetic product, a bioanalogue of humic substances. Obtained by autooxidation, produced in the form of an alkaline salt of high purity and constant composition (Rudgers-Werke, Germany). The starting products are aromatic polyhydroxy compounds, converted by a multi-stage reaction into a preparation with an average molecular weight of 1500. The resulting humic substance is completely and easily dissolved in water;

Peat biostimulator (BST). Developed at the All-Russian Research Institute of Peat Industry (St. Petersburg). The drug is obtained by oxidizing a water-alkaline suspension of peat with air oxygen. The resulting oxidation products are polyfunctional organic acids with a molecular weight from 1000 to 40000;

Oxidate - proposed by the Institute of Peat of the Academy of Sciences of the BSSR. It is obtained using new technology through the oxidation-ammoniation of peat organic matter. The drug is a liquid containing 5-10% dry matter, which contains a wide range of macro- and microelements.

Nitrohumic stimulant (NGS). The production technology was developed at the Kalinin branch of VNIITP by the method of oxidation of high-moor peats with a high degree of decomposition with nitric acid, followed by neutralization with ammonia water;

Gumadapt is a new humic preparation, a regulator of metabolic processes and an active detoxifier and others.

2. EXPERIMENTAL

2.1. Materials and research methods

The material for the study was vermicompost. (Application - I , Table 1), obtained in the mini-vermilaboratory of the Testing Laboratory of the Scientific Research Center "Agrotechnopark" of the Federal State Budgetary Educational Institution of Higher Professional Education of the Belgorod State Agricultural Academy named after V.Ya. Gorin from compost worms of the Belgorodskaya hybrid line (Application - II). This is a structured product of dark brown color with a pleasant earthy aroma. A humic preparation was obtained from it. The working solution of the humic preparation was prepared in distilled water by diluting the original concentrates. Testing of the biological activity of the resulting drug was carried out on cucumber seeds in accordance with GOST R 54221, pH - GOST R 54221.

The work also presents data from laboratory studies of the obtained humic preparation, which were carried out in an accredited testing laboratory using equipment and devices for chemical research of the composition of the preparations.

Based on the elemental composition data, changes in the chemical composition of microcomposites of the isolated fractions were assessed. The mass fraction of moisture was determined according to GOST R 52917; ash content - according to GOST 11022; total nitrogen, ammonium and nitrate nitrogen - GOST 26715, GOST 26716; free humic acids (HA) - GOST R 54221 and GOST 9517; R 2 O 5 and K 2 O - GOST 26 717, GOST 26718; mineral elements - according to GOST 30692; the determination of the group fractional composition of humus was carried out according to Tyurin’s scheme as modified by Ponomareva and Plotnikova.

Factors affecting the yield of humic acids: temperature, extraction time, alkali concentration, mass ratio of substrate: alkali. The optimal conditions for the extraction of humic acids from vermicompost are: extraction temperature - 25 0 C, extraction time - 24 hours, using a rotator - 240 min, alkali concentration for extraction - 0.2 N NaOH, acid concentration for precipitation of humic substances - 1 N H 2 SO4.

Security measures:

Hazard class of the drug - IV (low-hazardous substance)

When working, you must use gloves; you must not drink, smoke, or eat. After work, wash your face and hands with soap and water.

In case of contact with skin, wash with soap and water.

In case of contact with eyes, rinse with plenty of water.

3. RESEARCH RESULTS

By selecting parameters and reagents for the extraction and precipitation of humic substances, a humic preparation with a maximum yield of soluble humic acids was obtained.

Table 2 - Yield of humic acids

3.1. Physico-chemical composition of sodium humate

The chemical characteristics of the humic preparation are presented in Table 3 (data from the Testing Laboratory of the Belarusian State Agricultural Academy).

Table 3 - Physico-chemical composition of humus preparation

|

Indicator name |

SODIUM HUMATE |

|

Moisture, % |

|

|

Ash content, % |

|

|

Total nitrogen, mg% |

|

|

Ammonia nitrogen, mg% |

|

|

Nitrate nitrogen, mg% |

|

|

Free humic acids, g/l |

|

|

pH, units |

|

|

R 2 O 5, mg/l |

|

|

K 2 O, mg/l |

|

|

Sodium, mg/l |

|

|

Calcium, mg/l |

|

|

Cadmium, mg/l |

|

|

Lead, mg/l |

|

|

Arsenic, mg/l |

|

|

Mercury, mg/l |

|

|

Iron, mg/l |

|

|

Copper, mg/l |

|

|

Manganese, mg/l |

|

|

Zinc, mg/l |

|

|

Sulfur, mg/l |

|

|

Magnesium, mg/l |

When determining the pH of the prepared solution, it was found that the value of this indicator is in the range of 7.89-8.75, which suggests the stability of the drug with respect to photodestruction and increased resistance to light.

3.2. Study of the biological activity of the drug

In experiments on cucumber seeds under the influence of 0.005% aqueous solutions prepared from the studied drug, an increase in seed germination, biological activity of HA to increase the mass of seedlings, the length of stems and roots was noted on average by 2.0-4.0% (Table 4, Fig. 2-3). Seed germination on the third day of cultivation was 62% against the control 35%. That is, the entire drug served as a stimulator of seed germination in the test experiment.

Table 4 - Biological activity of humic preparations

Rice. 2. Study of the intensity of growth of germinal roots

Rice. 3. Study of the intensity of growth of germinal roots

testing method on cucumber seeds according to GOST R 54221-2010

4. CONCLUSION

The preparation SODIUM HUMATE was isolated from vermicompost (obtained by processing manure with compost worms of the hybrid line Belgorodskaya, Appendix - 2). The drug contains in 1 liter: humic acids of at least 78 g, nutrients phosphorus, potassium, sodium, sulfur and biogenic microelements.

The resulting drug can be used for the production of organic products, to increase crop yields. It is recommended to use the drug SODIUM HUMATE in the form of a working solution with a concentration of 0.005-0.01% of the main substance by pre-sowing treatment of seed or planting material and foliar treatment of plants during the growing season.

Economic efficiency- the use of humic preparations increases the yield of agricultural crops by an average of 5-17%.

5. REFERENCES

1.SanPiN 2.3.2.2354 - 2008. Sanitary and epidemiological rules and regulations, VI. Sanitary and epidemiological requirements for organic products. Additions and changes No. 8 to SanPiN 2.3.2.1078-01. Registered with the Ministry of Justice of Russia on May 23, 2008 No. 11741

2.GOST 9517-94 Solid fuel. Methods for determining the yield of humic acids - M.: ed. Standards. -1996

3.GOST 26713-85. Organic fertilizers. Method for determining moisture and dry residue. - M.: ed. Standards. -1986, p. 4-6.

4. GOST 26715-85. Organic fertilizers. Method for determining total nitrogen. - M.: ed. Standards. -1986, p. 9-20.

5.GOST 26716-85. Organic fertilizers. Method for determining ammonium nitrogen. - M.: ed. Standards. -1986, p. 21-28.

6. GOST 26717-85. Organic fertilizers. Method for determining total phosphorus. - M.: ed. Standards. -1986, p. 29-34.

7. GOST 26718-85. Organic fertilizers. Method for determining total potassium. - M.: ed. Standards. -1986, p. 35-38.

8.GOST 30178-1996. Raw materials and food products. Atomic absorption method for determining toxic elements

9.GOST 30692-2000. Feed, compound feed, compound feed raw materials. Atomic absorption method for determining the content of copper, lead, zinc and cadmium

10. GOST R 52917-2010. Humic preparations from brown and oxidized coals. Test methods. - M.: Standartinforma-2012

11.GOST R54221-2010 Humic preparations from brown and oxidized coals. Test methods. - M.: Standartinforma-2012

12.Asmaev M.P. Kinetic model of the process of obtaining vermicompost using vermiculture / M.P. Asmaev, D.L. Piotrovsky // Izv.university.food technology. -1997. - No. 2-3. P.84.

13. Balabanov S.S. Attempts to correct (accelerate) the natural process of humus formation in cultivated soils / S.S. Balabanov, N.I. Kartamyshev, V.Yu. Timonov, N.M. Chernysheva // Bulletin of the Kursk State Agricultural Academy. - 2010. -№ 1- p.63 - 66

14. Barne A. Zh. Dynamics of cocoon shedding in the compost worm Eisenia foetida / A. Zh. Barne // In: Proceedings of the 1st international conference “Earthworms and soil fertility”. - Vladimir, 2002. - P. 7 - 8.

15.Berkovich A.M. Antioxidant properties of a new veterinary drug containing humic substances - ligfol / A.M. Berkovich, S.V. Buzlama // Free radicals, antioxidants and animal health: international scientific and practical conference, September 21-23, 2004, Voronezh: collection. scientific tr. - Voronezh: VSU Publishing House, 2004. - P. 174-179

16.Biryukova O.N. Characteristics of organic matter of vermicomposts / O.N. Biryukova, Sukhanova N.I. // Materials of the IV International Congress on Bioconversion of Organic Waste/, Kovrov-2004

17. Bolotetsky N.M. On the technology of obtaining hybrid lines of the dung worm Eisenia foetida (Sav.) / N.M. Bolotetsky, Kodolova O.P., Nefedov G.N., Pravdukhina O.Yu., Truveller K.A. // In: Abstracts of the II International Congress. Bioconversion of organic waste from the national economy and environmental protection. - Ivano-Frankivsk. - 1992. - pp. 17-18.

18. Bykin A.V. Biological aspects of soil fertility reproduction when adding vermicompost. / Bykin A.V. // Agrochemical Bulletin. - 1997. - No. 6. - pp. 5-6.

19. Gogotov I.N. Characteristics of vermicomposts and soils produced by some Russian companies / I.N. Gogotov // Agrochemical Bulletin. - 2003. - No. 1. - page 11.

20. Gorovaya A.I. Humic substances. Structure, functions, mechanism of action, protective properties, ecological role / A.I. Gorovaya, Orlov D.S., Shcherbenko O.V. // Humic substances. Structure, functions, mechanism of action, protective properties, ecological role. - Kyiv, Naukova Dumka. - 1995.

21.Demin V.V. Probable mechanism of action of humic substances on living cells / V.V. Demin, V.A. Terentyev, Yu.A. Zavgorodnyaya, M.V. Biryukov. // In: Materials of the IV Congress of the Dokuchaevsky Society of Soil Scientists. Novosibirsk, August 9-13, 2004 - Novosibirsk, Science Center Publishing House, 2004. - P. 494

22. Yevloev Ya.V. Efficiency of modern forms of organization of agricultural production / Ya.V. Evloev // International Agricultural Journal. - 2000. No. 3 - p. 10 - 14.

23.Oliva T.V. Modern approaches to growing environmentally friendly crop products in protected soil conditions / T.V. Oliva // In: Solution of environmental problems in the production of agricultural products, Belgorod, 2004.-P.50-52.

24.Oliva T.V. Experience of growing environmentally friendly crop products in a greenhouse using vermicompost / T.V. Oliva, I.V. Nikolaeva // In: Materials of the All-Russian scientific and practical conference “Biotechnology in the service of agriculture”, Ryazan, 2004.- P.44 -48.

25. Orlov D.S. Comparative characteristics of some vermicomposts / D.S. Orlov, Ammosova Ya.M., Sadovnikova L.K. and others // In collection. : Abstract. report 3 international Congress “Bioconversion of Organic Waste”. - Moscow. - 1994 - pp. 69-70.

26. Orlov D.S., Sadovnikova L.K., Savrova A.L. // Reports of the Academy of Sciences, ser. "Geochemistry", 1995, 345(4), - P. 1-3.

27. Khristeva L.A. Effect of physiologically active humic acids on plants under unfavorable external conditions / Khristeva L.A. // Humic fertilizers: theory and practice of their application. Dnepropetrovsk, 1973, T.4, p.15-23.

APPLICATIONS

Application I

Table 1 - Characteristics of vermicompost based on cattle manure

|

№ p/p |

Indicators |

|

|

Mass fraction of moisture, % no more |

||

|

Organic matter, per dry product, %, not less |

||

|

Mass fraction of total nitrogen, per dry product, %, not less |

||

|

Mass fraction of total phosphorus in terms of P 2 O 5,%, not less |

||

|

Mass fraction of total potassium in terms of K2O, %, not less |

||

|

Mass fraction of mobile zinc, mg/kg, no more |

||

|

Mass fraction of mobile cobalt, mg/kg, not less |

||

|

Mass fraction of mobile copper, mg/kg, no more |

||

|

Weed seeds, thousand pieces, no more than 100 |

||

|

Viable helminth eggs, sporocysts |

none |

|

|

Pathogenic microorganisms, pcs./dm3, including salmonella |

none |

|

|

Pesticides in dry matter, mg/kg |

Application II

Photo 1. Compost worm from the genus Eisenia of the Belgorod line

Appendix III

Photo 2. Created vermicompost in vermitrack

The preparation contains a complex of compounds of humic and fulvic acids with phosphorus, potassium, nitrogen and microelements. In turn, all these substances have a positive effect on flower crops.

Sodium humate: description and composition

Sodium humate is a salt of humic acid. In Ancient Egypt, this substance was used as a remedy for. Then this process took place almost completely without human participation. The Nile River, emerging from its banks, flooded the nearby soil, and after the water receded, it was covered with a layer of fertile silt.

Today, brown coal, paper and alcohol production waste are used to produce sodium humate. Sodium humate as a fertilizer is also produced organically. It is a waste product of Californian worms, although ordinary ones are also capable of producing this substance.

The process of formation of sodium humate is quite simple: invertebrates absorb various organic wastes, which, after processing in the intestines, are converted into fertilizer.

The original consistency of sodium humate is a black powder that can be dissolved in water. But there is also liquid sodium humate. It is worth saying that humic acids in dry form are quite poorly absorbed due to their low solubility. Therefore, when using a plant growth stimulator such as sodium humate, it is advisable to give preference to its use in a liquid state.

Speaking about the composition of sodium humate, we should highlight the main active ingredient - sodium salts of humic acids. Acids are complex substances of organic origin. They contain more than twenty amino acids, carbohydrates, proteins and several tannins. In addition, acids are a source of wax, fats and lignin. All this is the remains of rotted organic matter.

Beneficial properties of sodium humate for plants

Numerous studies have shown that the substances contained in the sodium humate fertilizer have a positive effect on. Humates contain organic salts, which activate the supply of plants with all necessary microelements. In turn, these microelements stimulate the development of plants and increase their immunity.

It was also noted that sodium humate reduces the need for plants by up to 50%, and also increases productivity by 15-20%. This organic fertilizer restores the chemical and physical properties of the soil, which in turn increases plant resistance to radionuclides and nitrates.

Fertilizing with sodium humate provides:

Fertilizing with sodium humate provides:

- Increasing the amount of biologically active components in plants

- Better survival rate and germination when treating roots and before planting

- Accumulation of vitamins and nutrients in vegetables and

- Increased yield and accelerated ripening time

Did you know? The fact of the positive effect of sodium humate on plant development was first established at the end of the 19th century. After this, he found confirmation in many scientific works.

How to dilute sodium humate, instructions for use for plants

Sodium humate, used for or other plants, is best absorbed by them through the roots. To facilitate this process, it is necessary to prepare a special solution for. To prepare it, you need to take one tablespoon of humate, which is then dissolved in a ten-liter bucket of water. It is also necessary to mention that before using sodium humate, the plant must be gradually accustomed to such fertilizer.  So, after transplanting a plant, during the adaptation period, it is recommended to pour 0.5 liters of solution into the soil. Then, during the period when the buds are forming and blooming, the dosage of the drug should be increased to one liter.

So, after transplanting a plant, during the adaptation period, it is recommended to pour 0.5 liters of solution into the soil. Then, during the period when the buds are forming and blooming, the dosage of the drug should be increased to one liter.

Important! Sodium humate can be used to detoxify soil. In this case, the dosage is 50 grams of sodium humate for every 10 square meters of soil.

For seed treatment

Sodium humate is used for seed treatment in a proportion of 0.5 grams per liter of water. In order to accurately measure half a gram of the substance, you can use a regular teaspoon. The volume of a standard teaspoon is 3 grams. Based on this, half a gram is 1/3 of a teaspoon. It is better to stock up on a large volume of the substance; for this you need to dilute 1 gram of humate in two liters of water. To prepare such a composition, you can take a regular one, and then, if necessary, take a solution from it for treating seeds.  Sodium humate becomes liquid, and the instructions for using such sodium humate fertilizer are quite simple: the seeds are soaked in the resulting solution for two days (cucumber and flower seeds - for a day). After that, all that remains is to dry them well.

Sodium humate becomes liquid, and the instructions for using such sodium humate fertilizer are quite simple: the seeds are soaked in the resulting solution for two days (cucumber and flower seeds - for a day). After that, all that remains is to dry them well.

Did you know? To cultivate one hectare of land you need only 200 milliliters of sodium humate.

For irrigation

Often, sodium humate solution is used in the initial period, the application interval is 10-14 days. At the beginning, the dose per plant is 0.5 liters, after which it is increased to one liter. It is recommended to water the planted plants with humate immediately after planting or a few days later. The second watering is carried out during the budding period, and the third - during flowering.

To prepare the solution, you need to take one tablespoon of sodium humate and dissolve it in 10 liters of warm water. It is better to take a small volume of water with a temperature of approximately +50˚С. Humate is poured into it and mixed thoroughly. Later the remaining volume of liquid is added. Liquid sodium humate has a limited period of use, which is one month. All this time it must be stored in a dark, cool place.

Important! The humate solution must be poured directly under the root of the plant.

As a fertilizer

In this case, the concentration of the substance should be slightly lower. First of all, sodium humate is used for foliar feeding, that is, for spraying. This method has an advantage, since in this case the leaf blades are wetted, and all the beneficial substances are absorbed on the surface of the leaf and actively enter the plant.

At the same time, the consumption of the solution is significantly reduced, since you do not need to carry buckets throughout the garden. It is especially convenient to use sodium humate for spraying tomatoes. Preparing a solution for spraying involves diluting three grams of humate in 10 liters of water.

Soil treatment with sodium humate

A solution of sodium humate can improve the quality of the soil, as well as detoxify it. To do this, you need to scatter 50 grams of humate over an area of 10 square meters. To make it easier to distribute the substance over a given area, it can be pre-mixed with sand. After processing, the soil must be loosened using a hoe or rake.  Also, if you mix sodium humate with ash and sand, and then scatter this powder over the snow in early spring, you will prepare the bed for subsequent sowing. The snow will begin to melt much faster, and all you have to do is cover the area with film and the soil will be ready for planting.

Also, if you mix sodium humate with ash and sand, and then scatter this powder over the snow in early spring, you will prepare the bed for subsequent sowing. The snow will begin to melt much faster, and all you have to do is cover the area with film and the soil will be ready for planting.